Hi fiends, today was the day for the starter gear change and since this is my first step that deep into the engine, there is a couple of questions along the process that would be really nice getting some answers/input to.

I started out taking the right hand cover off, took off the gasket for the cover and scraped all remaining gaskets away from,the engine. Around every mounting hole there were gasket glued to the engine. It's all removed... So first question is would it be better when I mount the new gasket that the gasket gets glued to the cover and not onto the engine, that way I can save time eventually next time I'll have to do a similar maintenance inspection!?

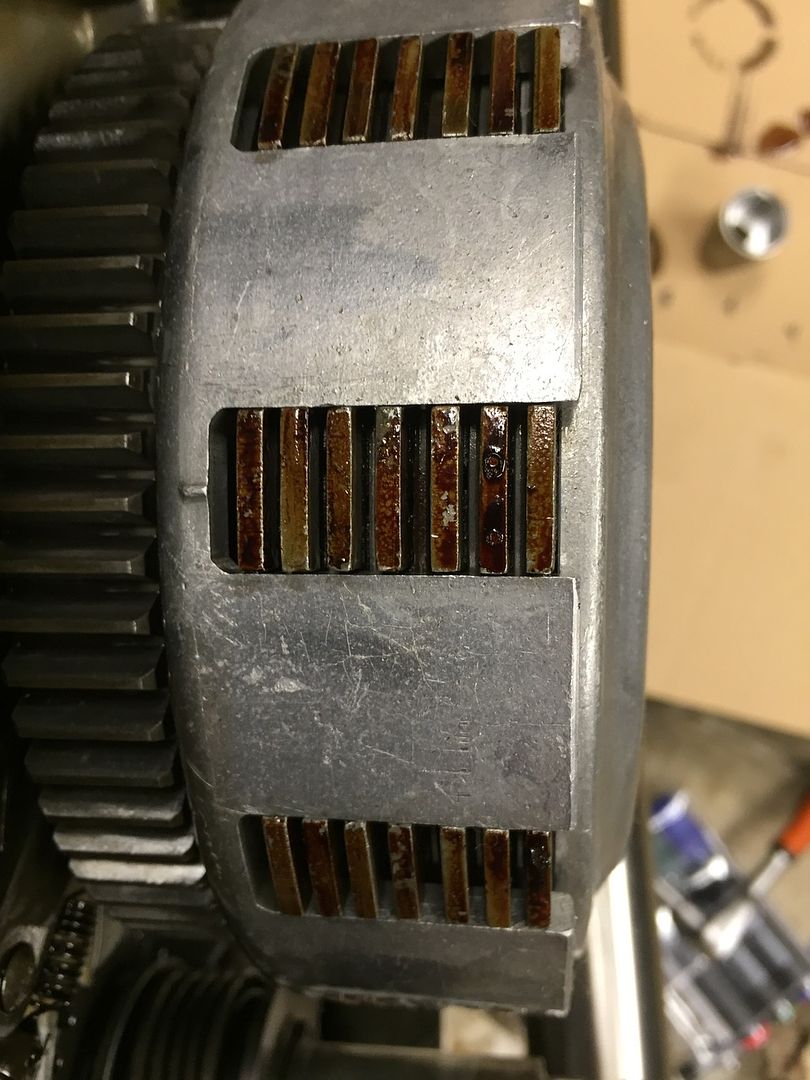

Second step were to unscrew the clutch basket and there were three short bolts and Springs and three long bolts and Springs... Seen in the picture below. Is that how it's supposed to be? And not six equally long screws and Springs!?

Next were to look at the next step unmounting the remaining clutch basket and the center piece/rod is that supposed to have a distance of a cm or two into the case??

The center rod is shown here, should it be flat to the case or stick out a few cm?

Then when I've removed it all and took out the starter gear and put the piece in the vice and tightened it up recounting the pieces and tested it would engage.. Wich it did without spinning around... Then I tested the clutch and noticed while doing so, that the clutch worked fine just discovered that three plates were moving out when pulling the lever.

Here it's mounted and lever isn't pulled as you might can see its mounted and flat alligned.

Second picture shows when I've pulled the clutch and it can be a little difficult to see when not filmed in action, but the three outer clutch plates were moving out not all of the plates...

Since this is my first time doing this it would be great to have a second opinion and some feedback on this thanks you all....

thanks you all....

Have a great Saturday

I started out taking the right hand cover off, took off the gasket for the cover and scraped all remaining gaskets away from,the engine. Around every mounting hole there were gasket glued to the engine. It's all removed... So first question is would it be better when I mount the new gasket that the gasket gets glued to the cover and not onto the engine, that way I can save time eventually next time I'll have to do a similar maintenance inspection!?

Second step were to unscrew the clutch basket and there were three short bolts and Springs and three long bolts and Springs... Seen in the picture below. Is that how it's supposed to be? And not six equally long screws and Springs!?

Next were to look at the next step unmounting the remaining clutch basket and the center piece/rod is that supposed to have a distance of a cm or two into the case??

The center rod is shown here, should it be flat to the case or stick out a few cm?

Then when I've removed it all and took out the starter gear and put the piece in the vice and tightened it up recounting the pieces and tested it would engage.. Wich it did without spinning around... Then I tested the clutch and noticed while doing so, that the clutch worked fine just discovered that three plates were moving out when pulling the lever.

Here it's mounted and lever isn't pulled as you might can see its mounted and flat alligned.

Second picture shows when I've pulled the clutch and it can be a little difficult to see when not filmed in action, but the three outer clutch plates were moving out not all of the plates...

Since this is my first time doing this it would be great to have a second opinion and some feedback on this

Have a great Saturday