Machi

XS650 Addict

My clutch action is stiff enough to hurt!

This is a '75 with a stock rebuilt engine. The clutch plates, springs and right hand mechanisms looked good and no upgrades or mods were done on that side before we buttoned it down.

It a one-piece push rod, I 'think' the bearing is in there on the right side.

First I had the '75 push lever on it and after some adjustment and fiddling the pull wasn't too bad, though finding neutral was a problem.

I changed the lever out for a used one - which is ~ 0.3" longer - off my '80. I was able to rehab the frozen lock nut that caused me to change it back when.

After two tries I still can't get it even as 'less stiff' as the '75 lever was working.

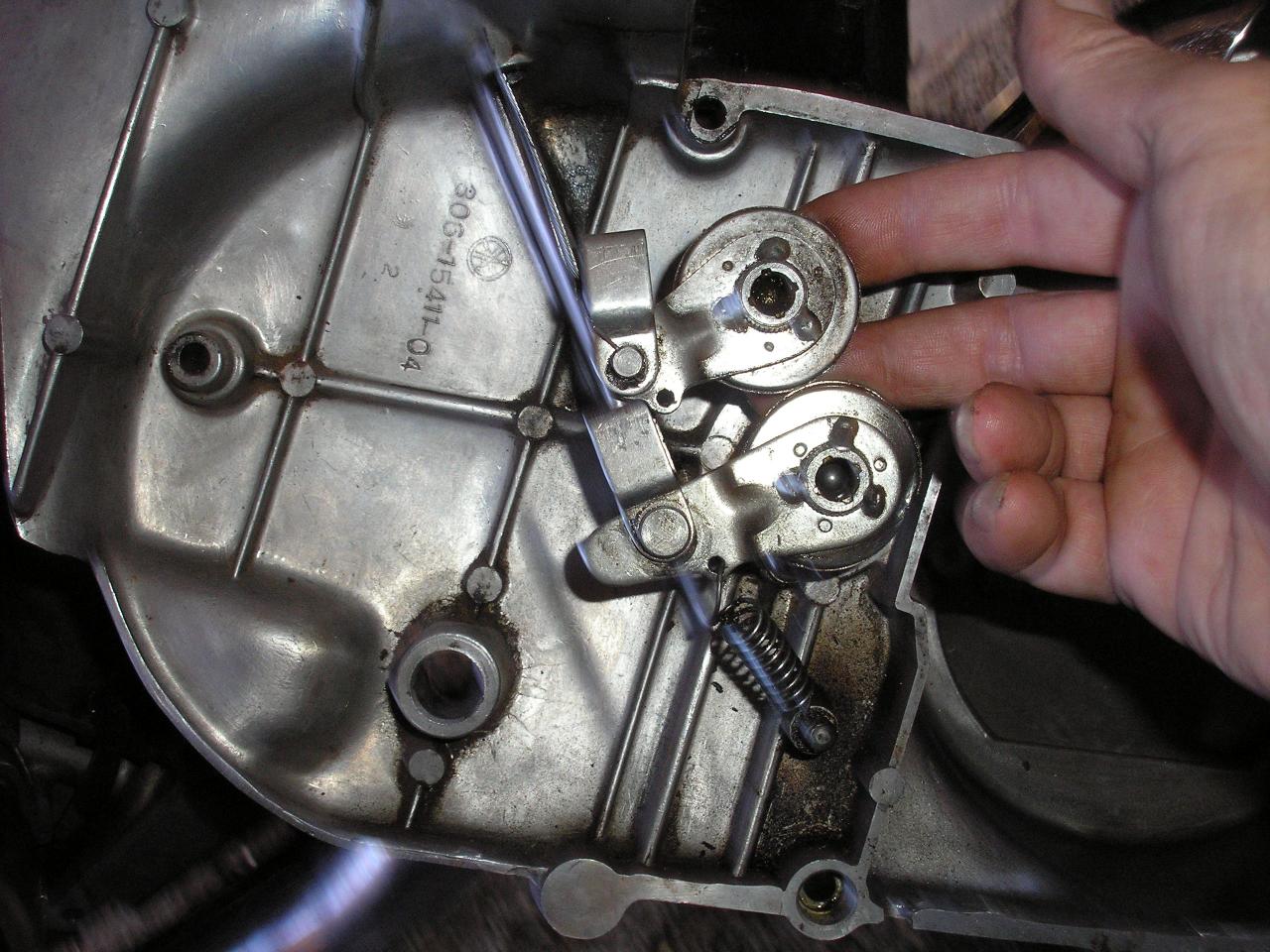

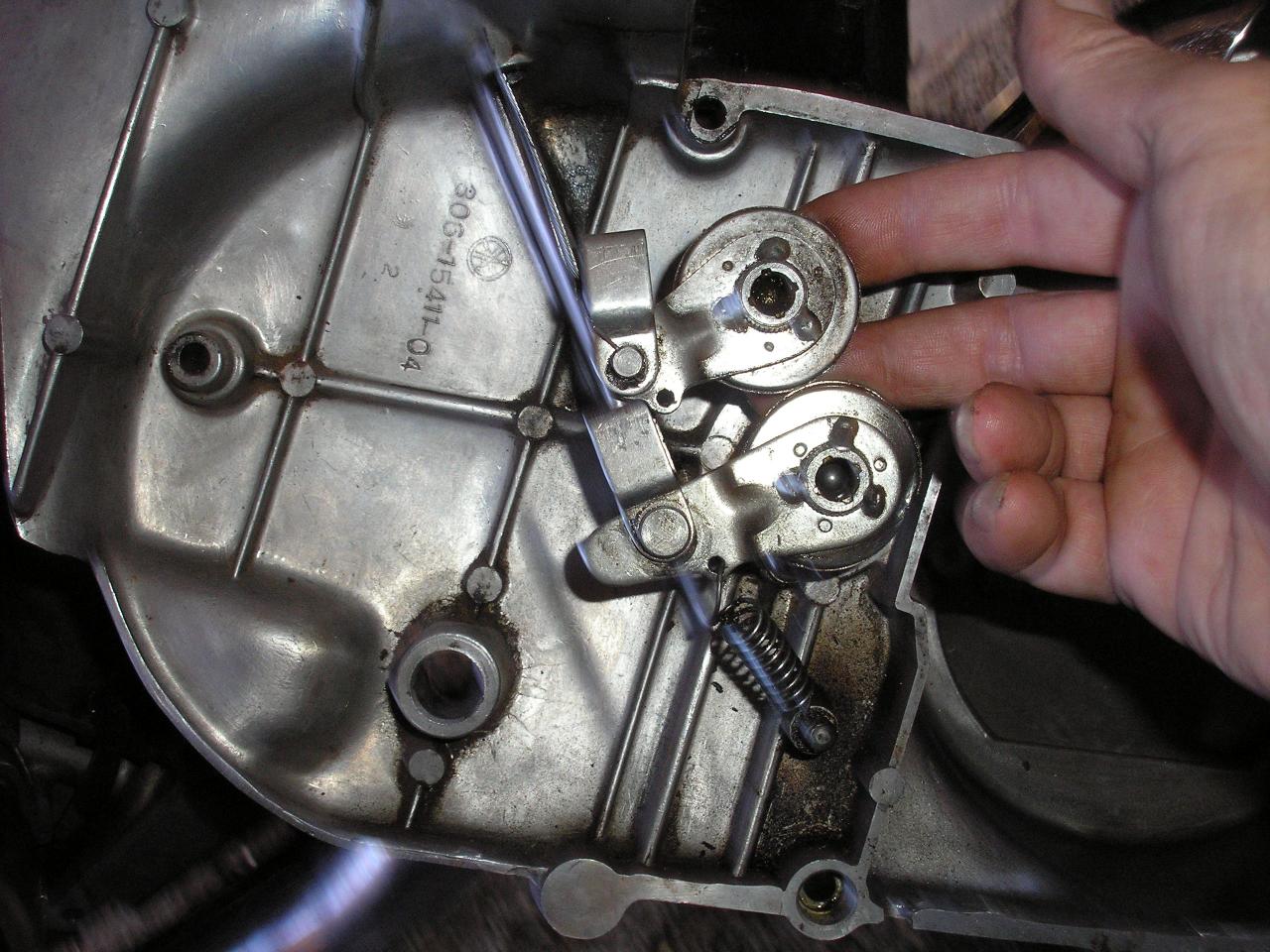

Here's a pic comparing the two (the '75 is at the top):

I am going to try a different angle on the lever and see how it works. I have read a lot of links here on these adjustments and this will be the 6th or 7th time I've done it, so I think I got the process down.

But I am starting to think the stiffness might be something on the right side. What should I look for over there if I decide to get into it?

Thanks

This is a '75 with a stock rebuilt engine. The clutch plates, springs and right hand mechanisms looked good and no upgrades or mods were done on that side before we buttoned it down.

It a one-piece push rod, I 'think' the bearing is in there on the right side.

First I had the '75 push lever on it and after some adjustment and fiddling the pull wasn't too bad, though finding neutral was a problem.

I changed the lever out for a used one - which is ~ 0.3" longer - off my '80. I was able to rehab the frozen lock nut that caused me to change it back when.

After two tries I still can't get it even as 'less stiff' as the '75 lever was working.

Here's a pic comparing the two (the '75 is at the top):

I am going to try a different angle on the lever and see how it works. I have read a lot of links here on these adjustments and this will be the 6th or 7th time I've done it, so I think I got the process down.

But I am starting to think the stiffness might be something on the right side. What should I look for over there if I decide to get into it?

Thanks

moments (of course).

moments (of course).