hard_y_rd

XS650 Guru

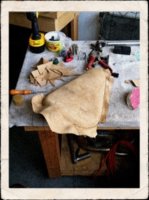

Just wondering if any of you lads tried rolling your own pan from 1/8 steel. I don't have fancy tools and want to do this pretty cheap. I picked up a piece of sheet metal and made a template. Enough to make 2 if I don't like my first. Just want to make a 3 inch sweep on the rear.

Got sick of building wheels, on to something different. I know, i'm all over the place on this build just want to stay motivated.

Got sick of building wheels, on to something different. I know, i'm all over the place on this build just want to stay motivated.