First off just want to introduce myself. I go by Bezz and I am a 30 year old mechanical engineer with a motor problem. I love everything motorized and have been wrenching and modifying my own junk since I brought a 77 F100 home when I was 12.

I have never done a build thread before but decided with this project to document my efforts to hopefully gain some input from the community, provide a place for others to learn (from successes and failures) and keep me motivated.

The build is called the Two Four build because that's what I paid for the bike, 24 cold beers. It is a 1979 xs650 and other than good compression on the motor, has nothing going for it.

Here is what I started with:

Started by completely tearing it down:

Had to make room in the garage to store the last bike I built. Bought it as a write off and completely rebuilt it from the bottom up, minus the engine:

The bottom fairing are removed for an oil change in this picture.

The blue you see in the lower right is my 1970 Nova that I am currently building as well.

I have never done a build thread before but decided with this project to document my efforts to hopefully gain some input from the community, provide a place for others to learn (from successes and failures) and keep me motivated.

The build is called the Two Four build because that's what I paid for the bike, 24 cold beers. It is a 1979 xs650 and other than good compression on the motor, has nothing going for it.

Here is what I started with:

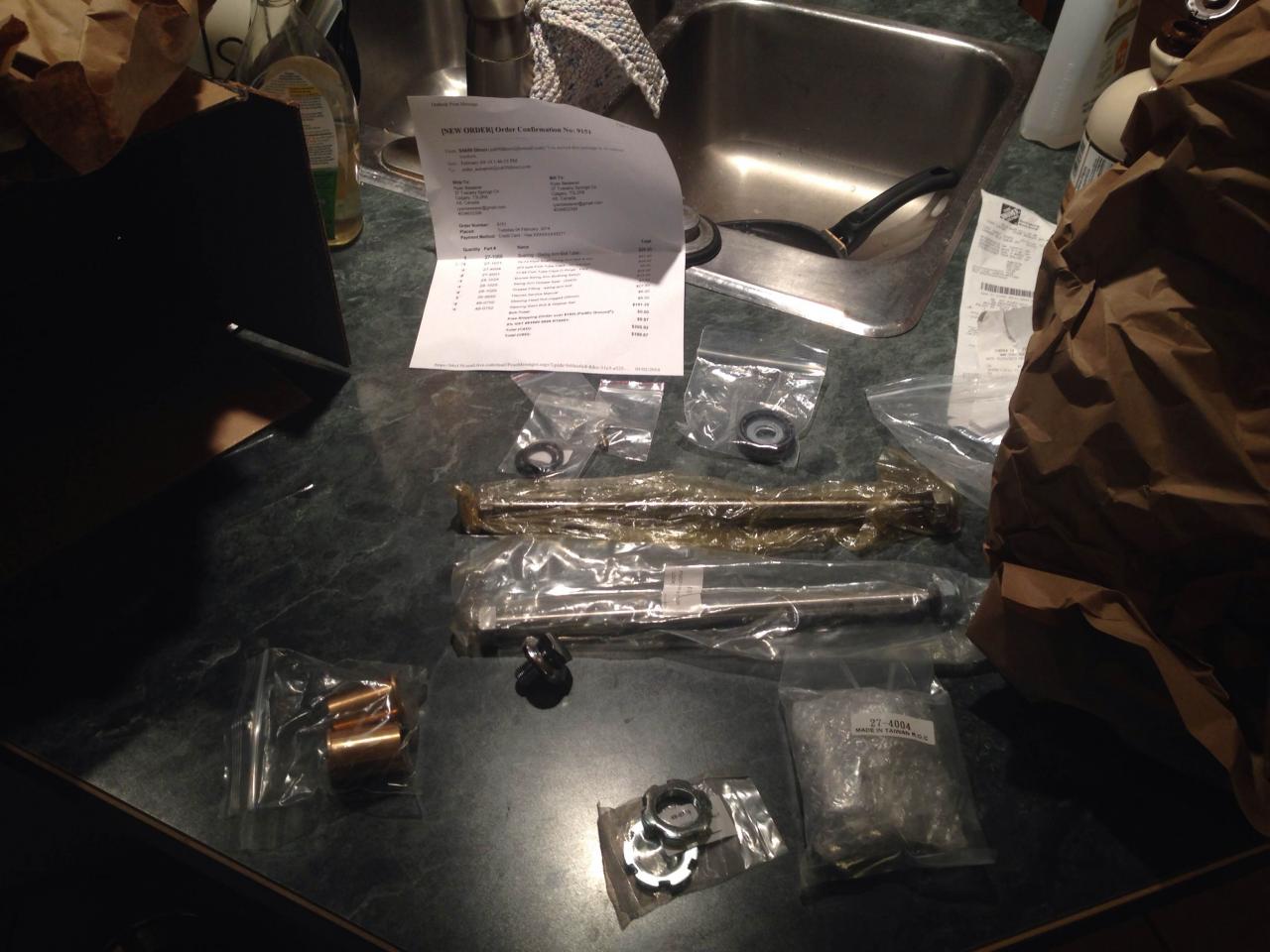

Started by completely tearing it down:

Had to make room in the garage to store the last bike I built. Bought it as a write off and completely rebuilt it from the bottom up, minus the engine:

The bottom fairing are removed for an oil change in this picture.

The blue you see in the lower right is my 1970 Nova that I am currently building as well.