Noticed the side stand was sloppy even with the spring attached so I unbolted it and cleaned it all up and then installed a brass shim around the shaft. It still had some play so I cut two strips of brass shim half inch wide and one inch long and put those in the gap between the stand bore and the shaft at 3 o'clock and 9 o'clock then re fitted the plate and bolt. It's not perfect but it won't drop down on its own so its an improvement until I can find a new stand.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What have you done to your XS today?

- Thread starter I am Carbon

- Start date

-

- Tags

- maintenance

Did I do this wrong. It is a Harbor Freight jack. It DOES have tie down loops on the rolling frame but using those locks you at a fixed height. Comments?

I didn’t see this when you first posted it, but I wanted to throw in my two cents. I have and use that same jack. The first thing I do is screw the floor locks down into place , so it won’t roll around. Then I usually jack it up to the height I want, then drop the lock down in place and then let the jack down until it’s resting on the lock, so if the hydraulic cylinder bleeds off it won’t surprise you and drop your bike. I use the tie down loops on the frame of the jack, I usually tie down all four corners, it only takes a few minutes and makes it so much more secure. Once it’s tied down like this I can even push the bike around in the garage to get it out of the way.

For general all around work blue magic at farm and fleet is my goto. At a minimum get a 4" drill powered cotton wheel to take some of the elbow grease out of it. Use a spritzer bottle of water, keep the cotton and the part wet for best polishing action.recommendations on alloy polish compounds?

This bike had been sitting for 20 plus years, was pretty grungy, near all blue magic work.

some with cotton buffs

Last edited:

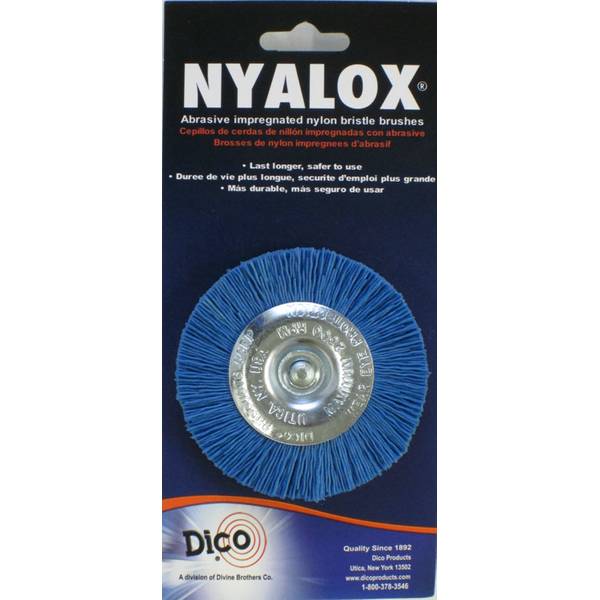

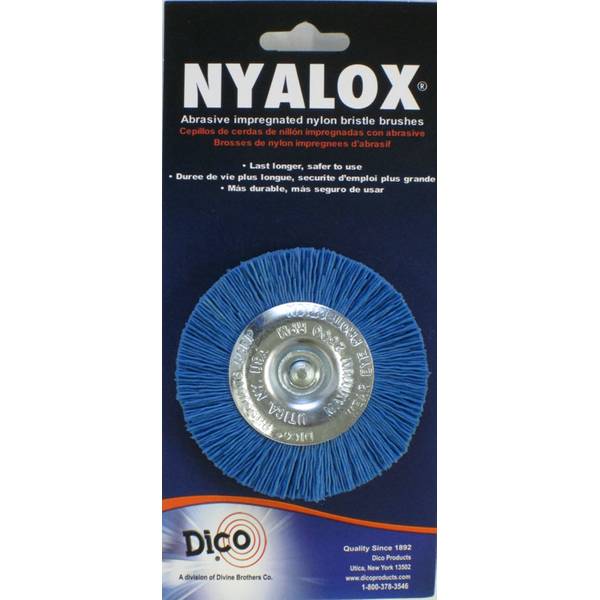

For uglier aluminum these are a good first step,

strong enough to remove light oxidation and any remaining clear coat, fine enough you won't spend the rest of your natural life removing scratches. I like a bit of mineral spirits or water with the dico wheel also, improves the abrasive action, reduces airborne dust.

For a good looking rider most of my work involves the dico then the blue magic. it won't make a mirror but shows well on the street.

strong enough to remove light oxidation and any remaining clear coat, fine enough you won't spend the rest of your natural life removing scratches. I like a bit of mineral spirits or water with the dico wheel also, improves the abrasive action, reduces airborne dust.

For a good looking rider most of my work involves the dico then the blue magic. it won't make a mirror but shows well on the street.

Your new space is looking awesome. Hats off to using the Habitat source. My local Habitat store is a "must visit" weekly.View attachment 202914

Repurposed some cabinets I got at Habitat's Restore. The formerly vertical one set crossways forms a void to hang up riding jackets.

Hoping to roll in a tool chest and my lift tomorrow.

Gary at your recommendation I bought a pair of these (blue and orange) and they did a great job cleaning up oxidation on my boat and utility trailer. I never tried them with any sort of lubrication though. What speed do you like to run them at? So far I’ve only used a drill but the ones I used only ran up to about 2500 rpm.For uglier aluminum these are a good first step,

strong enough to remove light oxidation and any remaining clear coat, fine enough you won't spend the rest of your natural life removing scratches. I like a bit of mineral spirits or water with the dico wheel also, improves the abrasive action, reduces airborne dust.

For a good looking rider most of my work involves the dico then the blue magic. it won't make a mirror but shows well on the street.

I have since the picture moved to 4 corner tie down on the rolling frame hoops. I failed to adhere to the sacred tenet of "if it moves, lube it" so while the jack rolls easily enough, I know I should have lubed the rollers before putting the bike on it. I just can't spray lube at those roller/caster wheels now and stain the garage floor.View attachment 202995

I didn’t see this when you first posted it, but I wanted to throw in my two cents. I have and use that same jack. The first thing I do is screw the floor locks down into place , so it won’t roll around. Then I usually jack it up to the height I want, then drop the lock down in place and then let the jack down until it’s resting on the lock, so if the hydraulic cylinder bleeds off it won’t surprise you and drop your bike. I use the tie down loops on the frame of the jack, I usually tie down all four corners, it only takes a few minutes and makes it so much more secure. Once it’s tied down like this I can even push the bike around in the garage to get it out of the way.

View attachment 202996 View attachment 202998

Speed varies, gotta slow down to get into slots, angles etc. Run dry and real fast, you CAN melt the ends of the bristles, which slows cutting action. I don't spin super fast. Orange and even gray have their uses but the scratches are deeper, so you go over with the blue then go to blue magic. Try with fluid see what you think. If you have a lot of clear coat start with paint stripper or acetone.Gary at your recommendation I bought a pair of these (blue and orange) and they did a great job cleaning up oxidation on my boat and utility trailer. I never tried them with any sort of lubrication though. What speed do you like to run them at? So far I’ve only used a drill but the ones I used only ran up to about 2500 rpm.

There have been two styles of dico wheels US made have a finer bristle Chinese made a larger stiffer bristle. the finer is much better IMHO. With reasonable pressure ie don't smash the wheel into your work piece these wheels are good for a LONG time I don't think there are ANY other abrasive products as durable as these. I've got a blue wheel around I've been using for over a decade. This is polishing 101. Do some searching in here for threads with lots of advanced show quality finish, methods and materials.

Last edited:

For the most part, I've found a 2500 RPM drill isn't fast enough for polishing. On the other hand, a die grinder (8 -10K RPMs) is too fast and as Gary mentioned, melts the bristles. I invested in a 4K RPM drill and get good results with it.

from Dico on the nyalox wheels; 3 color coded abrasive grits:gray is coarse, orange: medium, blue: fine.All with 1/4" quick change mandrel.Safer to use than wire brushes, safer for your project surfaces! Made in USA. Max RPM 2500. NEW & NOW AVAILABLE: WHITE NON ABRASIVE NYALOX FOR GENERAL CLEANING!

...and eye protection...

For the most part, I've found a 2500 RPM drill isn't fast enough for polishing. On the other hand, a die grinder (8 -10K RPMs) is too fast and as Gary mentioned, melts the bristles. I invested in a 4K RPM drill and get good results with it.

Like this one?

My electric drill is a 40 year old Craftsman, the damn thing just won’t die! I did however buy a Dewalt cordless drill that sees the most action anymore.

I have a corded drill, but I don't know how many RPM it turns. I don't recall the brand either. I'm sure it was cheap as I usually buy cheap until I break it, then follow with something better. Professional tools are another story. I used to work with a guy we called "Kroger Tools." (Kroger is a large grocery chain)My electric drill is a 40 year old Craftsman, the damn thing just won’t die! I did however buy a Dewalt cordless drill that sees the most action anymore.

For buffing dico wheel work I'm in year three of using a corded 3/8 VSR dewalt I got at a pawn shop for $10.

Yes, like that one, except mine is a Milwaukee. There aren't that many 4K RPM drills out there, and as you can see, they're not cheap, lol. We used them at work and I always wanted one, finally found a good deal on eBay (about $70). I worked with sheet metal siding and roofing, and most of our drilling was small holes up to about 1/4" dia. through sheet metal and steel up to about 1/4" to 3/8" thick. The 4K drills were ideal for this.

Yes, I saw that 2500 RPM limit on the Dico Nyalox wheels but they seem to work fine at 4K and clean better. Regular cloth buffing wheels definitely work better at 4K compared to 2500, so do wire wheels. The drills are variable speed so you don't have to run them at the max 4K, but it's nice to have that option.

Yes, I saw that 2500 RPM limit on the Dico Nyalox wheels but they seem to work fine at 4K and clean better. Regular cloth buffing wheels definitely work better at 4K compared to 2500, so do wire wheels. The drills are variable speed so you don't have to run them at the max 4K, but it's nice to have that option.

5T you might want to give a lower RPM and some water with a dico wheel a try, report what you think.

Hint; lower RPM reduces the mess with water involved. ;^)

Hint; lower RPM reduces the mess with water involved. ;^)

Similar threads

- Replies

- 32

- Views

- 1K