This thread covers all Yamaha XS650 Gauges from 1970 - 1984.......

Honda 70/71 750/4 KO post #8 .....by WideAWAKE

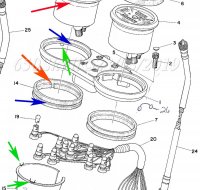

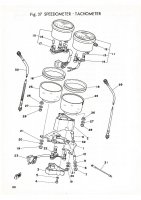

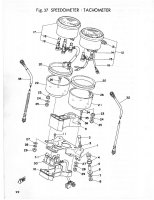

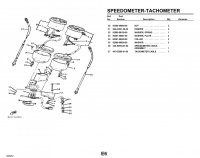

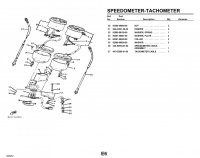

Parts Semantic 78-83 Specials

74-83 Bezel removal

1 This should be done on a soft surface so no damage will be done to the paint or metal ring. I used a folder that had a lot of paper work in it......This Bezel has been removed and reinstalled using this procedure.

2 before i started the second....3 a comparison of before and after...4 bend a screwdriver

......

...... ...............

...............

5 Using the screwdriver gently...pries the lip. NOTE: Do not try to pries open to much or you stretch the metal and it can't be returned in a neat fashion

6 Gently go around the gauge, (Note: but not the full way around leave an inch or so as in Pic #10). The lip is stretched so gentle small increments does the least damage and is easier to reinstall

7 Gently Bentley..............................8 the lip is getting to the fully opened stage

..........

..........

9 What the lip looks like when it is ready to slip off

10 Leave a small piece of the lip not pried at all to help with the tension when reinstalling and tapping back down........Need to wiggle a bit to get off and when reinstalling

11 Using the screwdriver gently insert under the ring and lever against the plastic case. If the ring has not been pried open enough it will be hard to slip of........Don't force it may need to do some extra stretching......When at this stage it is surprising how much leverage is needed to get that extra stretch out of the lip

Honda 70/71 750/4 KO post #8 .....by WideAWAKE

Parts Semantic 78-83 Specials

74-83 Bezel removal

1 This should be done on a soft surface so no damage will be done to the paint or metal ring. I used a folder that had a lot of paper work in it......This Bezel has been removed and reinstalled using this procedure.

2 before i started the second....3 a comparison of before and after...4 bend a screwdriver

......

...... ...............

...............

5 Using the screwdriver gently...pries the lip. NOTE: Do not try to pries open to much or you stretch the metal and it can't be returned in a neat fashion

6 Gently go around the gauge, (Note: but not the full way around leave an inch or so as in Pic #10). The lip is stretched so gentle small increments does the least damage and is easier to reinstall

7 Gently Bentley..............................8 the lip is getting to the fully opened stage

..........

..........

9 What the lip looks like when it is ready to slip off

10 Leave a small piece of the lip not pried at all to help with the tension when reinstalling and tapping back down........Need to wiggle a bit to get off and when reinstalling

11 Using the screwdriver gently insert under the ring and lever against the plastic case. If the ring has not been pried open enough it will be hard to slip of........Don't force it may need to do some extra stretching......When at this stage it is surprising how much leverage is needed to get that extra stretch out of the lip

Last edited: