cbuckle

XS650 Enthusiast

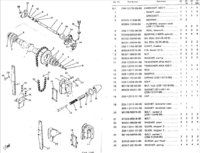

First time former, I have a 1974 TX650A with 2500 miles which has not seen a spark in 30 years, I've read a pile of information on the bike and still learning. When cleaning the points and cam I noticed the cam has a keyway cut in it, but the 'cam rod' on the threading does not have a keyseat. After losing off the nut I was able to freely spin the cam.

To properly set the timing now should I use the rotor/stator at TDC on the right cylinder compression stroke, then adjust the CAM to where I first get a short on the right cylinder point? Or use F marker instead of TDC?

I also read on how to make a spark by spinning this CAM by hand. Is this a good idea to confirm spark and point gaps setting?

http://www.xs650.com/forum/showthread.php?t=11271&highlight=cam+rod

Many thanks

To properly set the timing now should I use the rotor/stator at TDC on the right cylinder compression stroke, then adjust the CAM to where I first get a short on the right cylinder point? Or use F marker instead of TDC?

I also read on how to make a spark by spinning this CAM by hand. Is this a good idea to confirm spark and point gaps setting?

http://www.xs650.com/forum/showthread.php?t=11271&highlight=cam+rod

Many thanks