Bob Kelly III

Ranch Kid from way back,.... that got Old !

OK Stupid question .... where is the How to make the vynal hose carb syncronizer at ?

I've looked all over and I can't find it.

I think I could figure out how to make one myself but I prefure not to suck automatic trans fluid into my engine should I be wrong ....HEHEHEHEH !

I have a UNI-SYN carb syncronizer which only a few of you have probably ever hurd of ... its a aluminum cast large washer with a rubber pad on it for placing on the carb intake. it has built into it a venturi that has an adjustable plug in it's center, you adjust the plug in and out to raise or lower the amount of vaccuum for a reading... the reading is taken from a bolted on sight tube with a small light plastic cap .... the sight tube has to be vertical to work the best otherwise small adjustments won't effect it.... the problem with using it on the XS650 is that the sight tube is on the left which is great when adjusting the right cylinder but bad for the left as it hits the down tube between the carbs....

so I figured I'ed make a carb syncronizer for the XS650 and not have to guess at the angle I am holding it on the left side and try to reproduce the same angle for the right... ( which by the way seamed to work very well) ... but I want to be more accurate than guesswork !

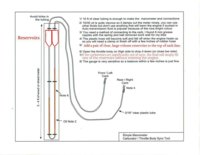

I have seen many carb syncronizers in the past, most are rediculasly expensive.... and their just clear tubes with a heavy liquid in them some have valves at the ends that must be set to certain openings for diferent bikes....

I do know that you don't touch the throttle when Using the Murcury filled ones unless you want to have the murcury sucked into the engine.... so that probably goes for the oil filed ones as well.

I would prefure to have NO oil or water or anything else, but a floating indicator that is trapped so it cannot get out....

if you can point me in the right direction to find Travis's carb sync-er I'ed appreaciate it .

or perhaps you have a idea to make one that would not have the danger of the indicator being sucked into the engine.... that would be great as well....

there is enough Inovateive people on here that surely some of you have figured this out already !

and hopefully you would like to share how to make it and use it !

Thank you very much !

Bob............

I've looked all over and I can't find it.

I think I could figure out how to make one myself but I prefure not to suck automatic trans fluid into my engine should I be wrong ....HEHEHEHEH !

I have a UNI-SYN carb syncronizer which only a few of you have probably ever hurd of ... its a aluminum cast large washer with a rubber pad on it for placing on the carb intake. it has built into it a venturi that has an adjustable plug in it's center, you adjust the plug in and out to raise or lower the amount of vaccuum for a reading... the reading is taken from a bolted on sight tube with a small light plastic cap .... the sight tube has to be vertical to work the best otherwise small adjustments won't effect it.... the problem with using it on the XS650 is that the sight tube is on the left which is great when adjusting the right cylinder but bad for the left as it hits the down tube between the carbs....

so I figured I'ed make a carb syncronizer for the XS650 and not have to guess at the angle I am holding it on the left side and try to reproduce the same angle for the right... ( which by the way seamed to work very well) ... but I want to be more accurate than guesswork !

I have seen many carb syncronizers in the past, most are rediculasly expensive.... and their just clear tubes with a heavy liquid in them some have valves at the ends that must be set to certain openings for diferent bikes....

I do know that you don't touch the throttle when Using the Murcury filled ones unless you want to have the murcury sucked into the engine.... so that probably goes for the oil filed ones as well.

I would prefure to have NO oil or water or anything else, but a floating indicator that is trapped so it cannot get out....

if you can point me in the right direction to find Travis's carb sync-er I'ed appreaciate it .

or perhaps you have a idea to make one that would not have the danger of the indicator being sucked into the engine.... that would be great as well....

there is enough Inovateive people on here that surely some of you have figured this out already !

and hopefully you would like to share how to make it and use it !

Thank you very much !

Bob............