Tiesco

XS650 Addict

Before I begin I would like to direct you to this thread. ( https://xs650temp.proboards.com/thread/7899/19-junkyard-electronic-ignition ) It's pretty straight forward and Mr. Riggs knows much more than I. Please correct any misinformation that I spread. I'm still learning as I go along. I plan on just condensing the information to the best of my understanding(which isn't all that much) and making it a bit easier to find. I'm no expert I just want to share this information seeing as I haven't seen all that many people showcasing this setup. I hope these threads are useful to you.

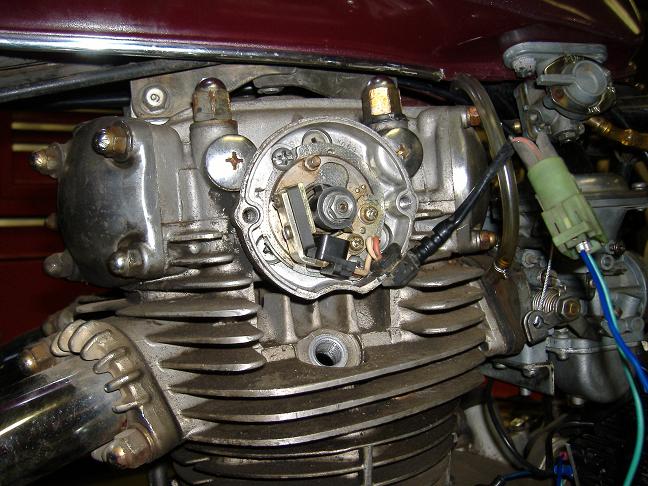

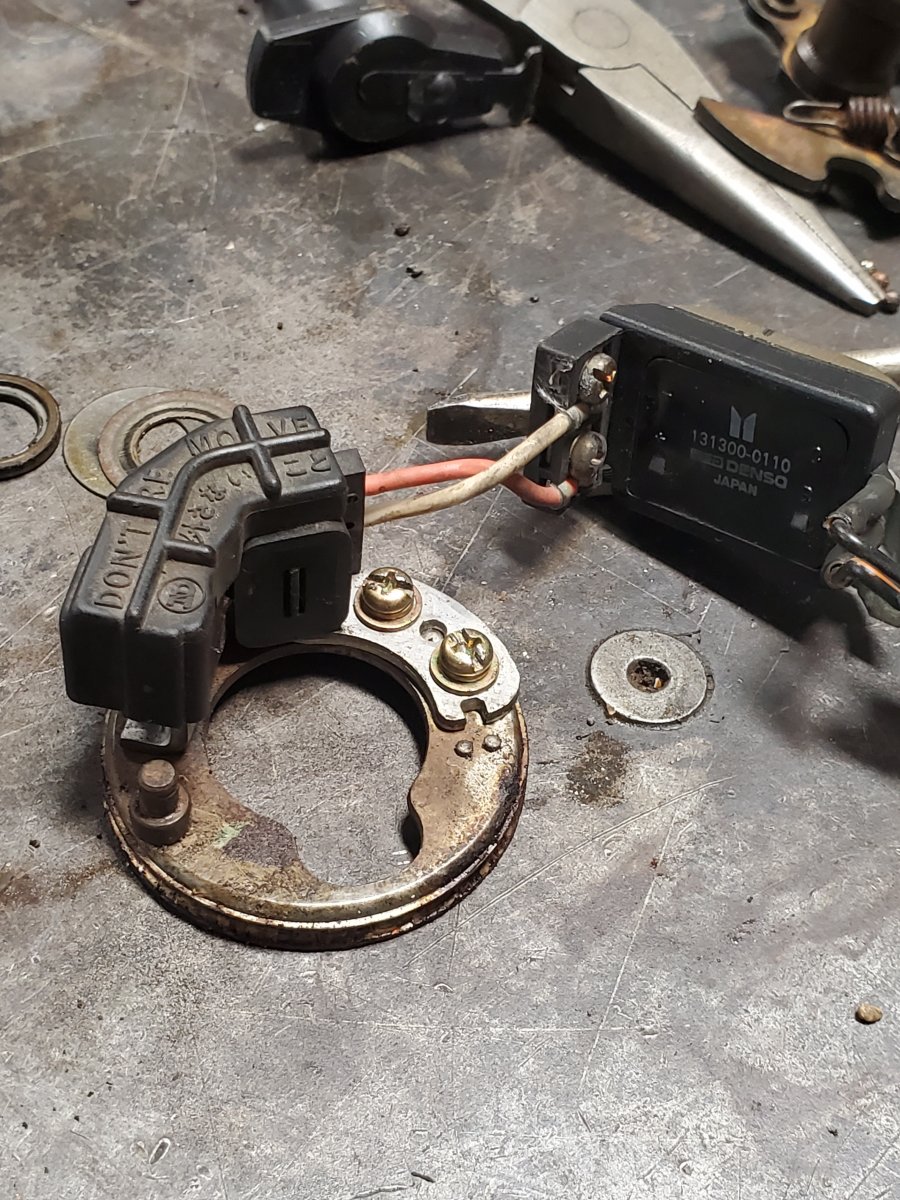

I have been planning on putting an electronic ignition on my 77 since I bought it. I was having trouble finding a new set of points and the ones I had were badly worn. I started looking around for electronic ignitions and came across this thread. Mr. Riggs used the pickup and reluctor out a Toyota 22R motor from the 80s. Here's a part of Mr Riggs setup.

I found my parts our of a 1985 Isuzu pickup truck. There really isn't that much of a difference.

It easily fits up against the points plate but you'll have to grind off the little pins off.

There will be more to follow.

I have been planning on putting an electronic ignition on my 77 since I bought it. I was having trouble finding a new set of points and the ones I had were badly worn. I started looking around for electronic ignitions and came across this thread. Mr. Riggs used the pickup and reluctor out a Toyota 22R motor from the 80s. Here's a part of Mr Riggs setup.

I found my parts our of a 1985 Isuzu pickup truck. There really isn't that much of a difference.

It easily fits up against the points plate but you'll have to grind off the little pins off.

There will be more to follow.

Attachments

Last edited: