I am Carbon

shade tree mechanic

I had to do a small mod to make the job easier

I've read about the procedure many times but I wouldn't be afraid to do one myself now. Thanks again and keep em coming. Think we will be seeing you dismantle a lower end?

jefft

There's a coupe out thereThink we will be seeing you dismantle a lower end?

Yup, pretty much the way I did mine, smoothing that edge with a dremel tool.

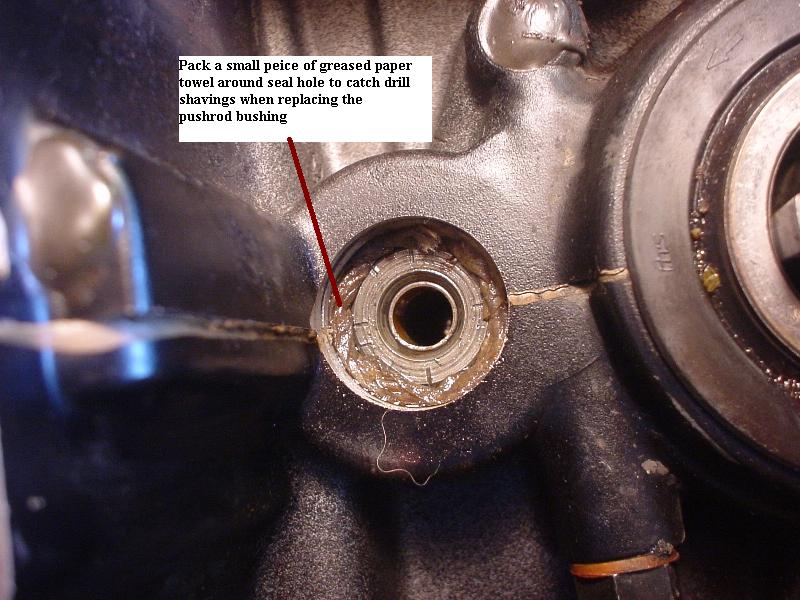

Also, once I get that seal out, I check the rod for play. If I get some wiggle, I replace the bushing too. Just like it says on MikesXS with a drill, cleaning out the hole with a Que-Tip, being very careful not to push any metal bits inside.

@ I am carbon

Why did you leave the push rod and drive sprocket in/on during the procedure?

it was the first time for me. maybe I was scared

it was the first time for me. maybe I was scared

(But, I almost lost a ball in the process).

(But, I almost lost a ball in the process).Sucked my own rod and got a happy ending...(But, I almost lost a ball in the process).Rich

Ok, so here's yet another / different way to do it...

I was able to get the bushing out by tapping it 3/8" (removal and cleaning out the minor shavings a few times before going in all the way) and inserting a 3/8"x8" bolt. I slipped a large socket on to the bolt(redneck slide hammer). And, with two little slaps, out comes the bushing. Took 5 minutes total and very little shavings to speak of.

So, with that said, I put a shop vacuum up to the hole to clean up any remaining shavings. And, I said to myself. "Self". Instead of trying to pull out a stubborn rod(which already didn't come out with a magnet), why not let the shop vac pull it out? 2 seconds of suction pulled both the rod and the remaining ball bearing out as easy as can be.

Note to self: Clean out the shop vac before attempting this again. It took more time to find the ball bearing in the bottom than it did to do the entire afore mentioned procedure....

Sucked my own rod and got a happy ending...(But, I almost lost a ball in the process).

Thanks again for all of the help!

Rich

So if the back of my shirt has oil splattered on it and my chain is extremely oiled is that a good indication I need to replace the clutch seal rod?