Well, hang in there. It may not work with the parts you have. So far, in your vid, the first 2 washers seem to place the basket in the appropriate alignment with the primary drive gear.

The real problem here is the excessive exposed spline after fitting the hub. The hub is spaced out by the washers with the smaller ID's, and the inner bush of the basket.

It's one thing to repair a machine that was working correctly prior to breakdown.

It's something else trying to assemble a basket case or an unproved frankenbike.

So, was it working fine before? Or is this an unfinished 'project'?

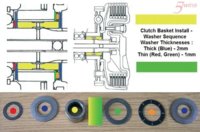

This is where I get out the micrometers, measure and sketch, and derive running clearances using sideviews like that posted above. The idea of 'throwing it together' would be out the door.

Again, the hub fitting too deeply onto that driveshaft is a warning sign. Unfortunately, I don't have the factory drawings showing the manufacturing dimensions, so no help there.

If the bike was here in my shop, we could get this to work, possibly machining special spacer washers, ensuring proper dimensional and clearance setups. Kinda like reinventing the wheel...