sseres

XS650 Junkie

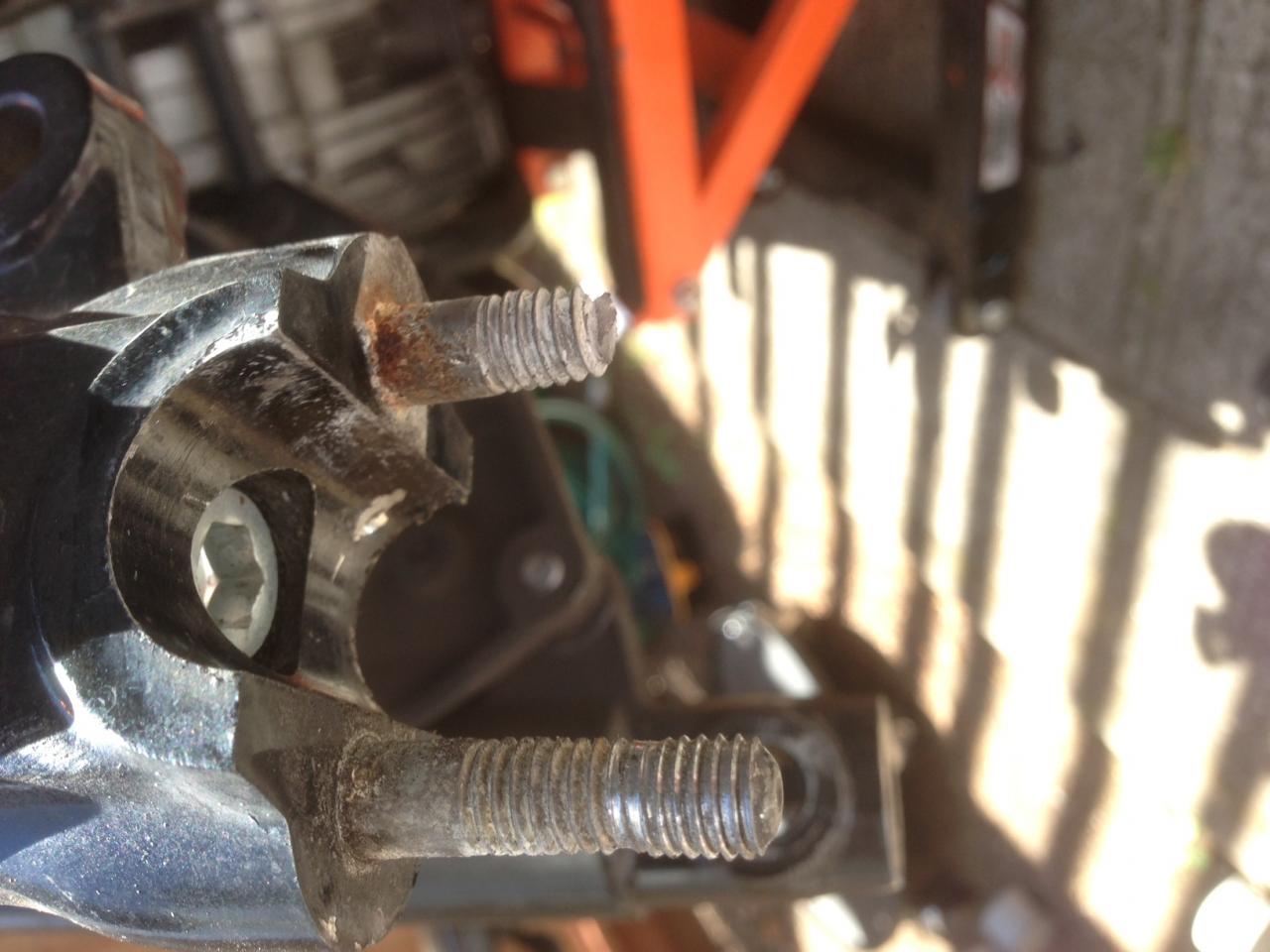

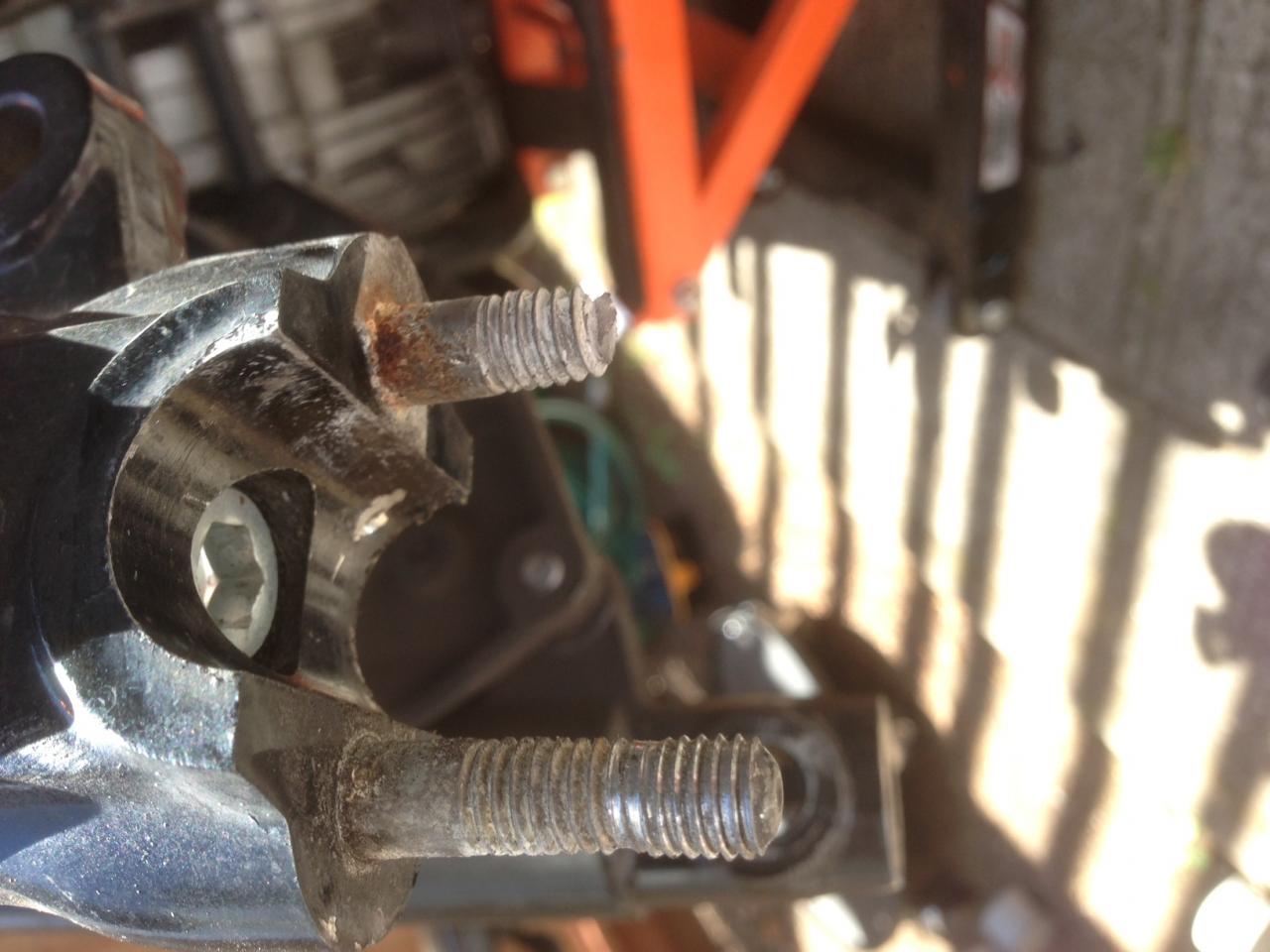

man.... this bike and broken bolts. I was taking the front wheel off today to get a new rotor on, and one of the two bolts at the end of the left fork broke off in my hand! It looks like a stem, you know, a bolt with threads at both ends? Anyway, do I have a snowball's chance of getting what's left out and put a new one in, or is this more serious? It actually looks like the other one has been stretched out, too, but it's not broken.... yet