Run the adjuster nut up tight, then tighten the axle.torquing the rear axle whilst applying the rear brake

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Do you think this would work?

- Thread starter Mailman

- Start date

Run the adjuster nut up tight, then tighten the axle.

Well hell! That just makes too much sense! Learn sumthin' new everyday..........lol

Cheeses Kay Riced, guys, you're not lifting a half ton of diesel motor, you're lifting an air cooled 2-banger that weighs less than160 lbs! Here's the drill I've followed for years, for what it's worth.

1. Strap bike down on lift. Remove all motor mounts. Insert one bolt in back of motor and one bolt in front. Put a loop of a tie down strap on each end of each bolt.

2. Throw a ratchet tie down over a rafter above each strap. That's right, kids--a cheapass ratchet tiedown with a nylon or poly strap--remember, each one is only going to lift 80 lbs. Attach a hook to each strap on the motor. Crank 'er up.

3. When the motor is a bit free, finesse it out of the frame, roll the lift with bike away, and scoot a table under the hanging motor Let the motor down and do the needful.Use wooden blocks, etc. to position and support the motor while you work: engine stands are for sissies.

if you have the bike on a lift already , wouldn't you just lower the lift until the beam carried the weight of the engine ..

It would save a lot of grunting ,....cussing and scraped knuckles trying to lift the engine with tie straps

You don't reset it as you adjust the chain? IME it gets tighter as the axle is drawn rearwards.

Well, Peanut, you could do it that way, but to wiggle the motor out of the frame you need clearance at both top and bottom of the motor, and I find it easier to find the sweet spot by controlling the ratchets rather than the hydraulic release. Grunting, straining and knuckle skinning are only part of the picture if you let your imagination run without experience to rein it in.

well lifting an engine out with tie down straps all sounds a bit Heath Robinson to me... but then,... in my youth I was strong and dumb enough to lift a 4x pot Triumph Spitfire engine out of a car with a piece of rope looped around my neck. !

but then,... in my youth I was strong and dumb enough to lift a 4x pot Triumph Spitfire engine out of a car with a piece of rope looped around my neck. !

These days I'm sensible enough to use the correct tool for a job.

heres how the Girlies do it ...........

These days I'm sensible enough to use the correct tool for a job.

heres how the Girlies do it ...........

I see the misunderstanding now--there's no way my 70 year old back would take it if I tried picking up that motor by heaving on a pair of straps! OK: Tool 1: Handlebar straps from tie down kit (nylon straps with a loop at each end). Tool 2: Poor boy's hoist--ratchet tie downs hooked onto Tool 1, lifting done with finger pressure. The bike is strapped down to the lift only to stabilize the chassis while the engine gets wiggled out.

Sure, I've removed/installed the motor by lifting/lowering the rolling chassis, but the slug still has to be lifted to and from the bench. Used to get that done by using a 2x6 board for a ramp and horsing the beast up.

Sure, I've removed/installed the motor by lifting/lowering the rolling chassis, but the slug still has to be lifted to and from the bench. Used to get that done by using a 2x6 board for a ramp and horsing the beast up.

I can remember being shocked at how heavy/unwieldy a complete XS650 engine felt. The last time I had to deal with was when I was around 30, hale and hearty. But cripes was it unwieldy. I think I got some help from my wife or my stepson and most likely used Downeaster's laudably honest method. I think I strapped the frame down to a table, covered up the tubes to avoid scratching and just used brutality and profanity to get it in place. I think removal was similar, but the lay-down-the-frame-method seems awfully intuitive and popular here as well as with Sportster folk.

When I was young and full of hope I used to lay over the frame rails of my 87 GSXR and hulk the motor in and out. I think it comes down to what you think you can get with and/or how much you look up to Wile E. Coyote.

But I don't think anybody has given bad advice here.

A nice sturdy table for this stuff helps. I had a lift like yours and things can get difficult with the available height.

When I was young and full of hope I used to lay over the frame rails of my 87 GSXR and hulk the motor in and out. I think it comes down to what you think you can get with and/or how much you look up to Wile E. Coyote.

But I don't think anybody has given bad advice here.

A nice sturdy table for this stuff helps. I had a lift like yours and things can get difficult with the available height.

I see the misunderstanding now--there's no way my 70 year old back would take it if I tried picking up that motor by heaving on a pair of straps! OK: Tool 1: Handlebar straps from tie down kit (nylon straps with a loop at each end). Tool 2: Poor boy's hoist--ratchet tie downs hooked onto Tool 1, lifting done with finger pressure. The bike is strapped down to the lift only to stabilize the chassis while the engine gets wiggled out.

Sure, I've removed/installed the motor by lifting/lowering the rolling chassis, but the slug still has to be lifted to and from the bench. Used to get that done by using a 2x6 board for a ramp and horsing the beast up.

well when equipment is in short supply .........you need to improvise and there is nothing wrong with your method .

I'm 3x years off 70 myself and I would think twice now about lifting the engine in out in, my hands... like I did in the video 5 years ago.

Sliding on a ramp sure sounds like a sensible way to me to get the beast on the bench.

And then there was late Shell Thuet, master tuner and the privateer racer's best friend. According to reliable reports, he was lifting XS650 motors onto the bench by hand at the age of 90. They don't make 'em like that any more, and I suspect they only made one back in the day.

Meddy

XS650 Addict

My thought is to hang the cable winch from a rafter, pick up the frame with the engine off of the bike jack with the cable winch.

Then set all that down on the ground, lay it over sideways on some cardboard, unbolt the motor and lift the frame off. Then re attach the cable winch and lift the motor back up, set it on the dolly, so I can roll it around.

Does that sound like it would work?

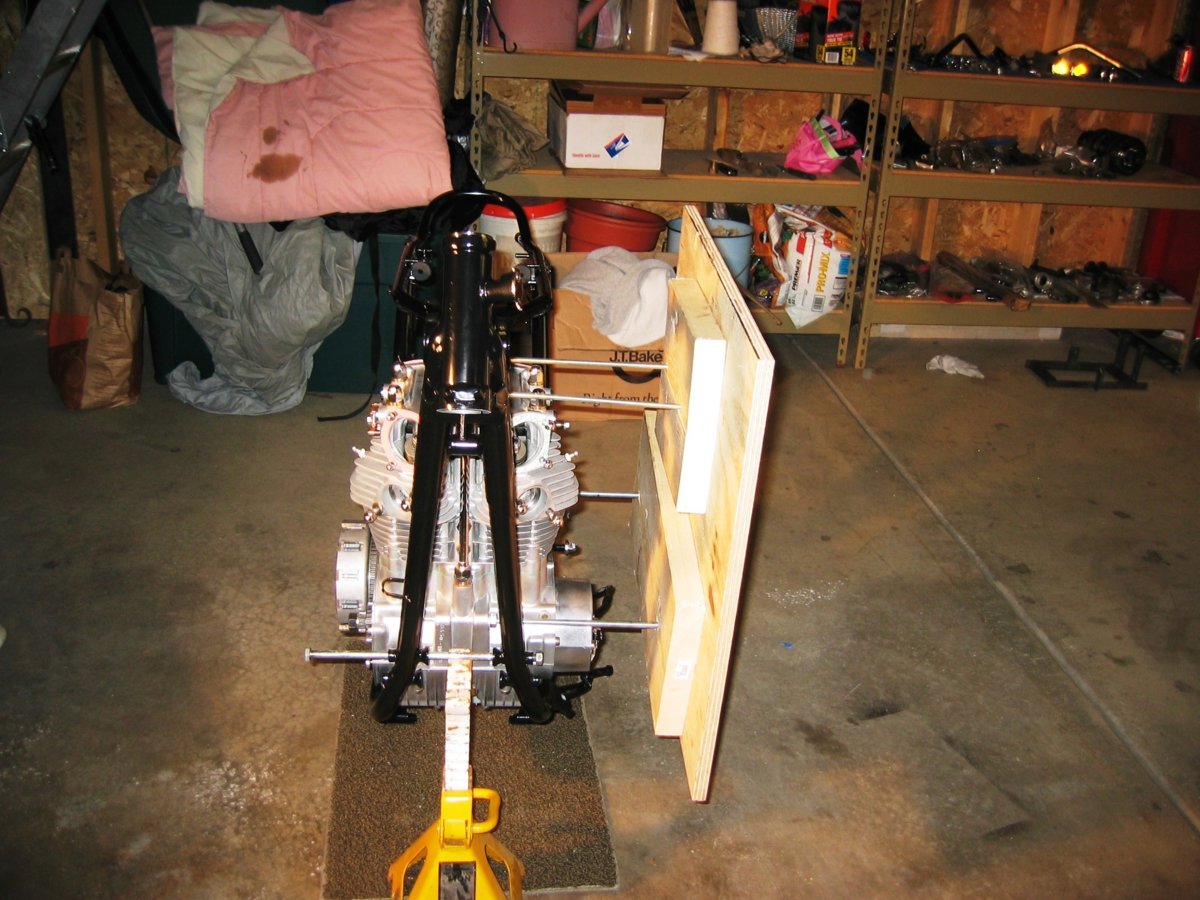

Yes, that will work Bob, here's my motor going in the frame, exactly as you proposed.

Well I’ve just kind of stood back and let you all give suggestions, and some really great suggestions included in there too.

So here’s where I’m at. First of all, no way I’m wrestling that lump by hand by myself.

After posting this , my friend and forum member Daniel Black offered to come over and help me do it whenever I’m ready.

And......as a back up plan, I went ahead and bought that 4 ton come along from Harbor Freight. I mean it was on sale and I had a coupon, it wound up costing me $13.

So thanks to all that contributed their suggestions, I now have a plan. And you know what they say about plans!

So here’s where I’m at. First of all, no way I’m wrestling that lump by hand by myself.

After posting this , my friend and forum member Daniel Black offered to come over and help me do it whenever I’m ready.

And......as a back up plan, I went ahead and bought that 4 ton come along from Harbor Freight. I mean it was on sale and I had a coupon, it wound up costing me $13.

So thanks to all that contributed their suggestions, I now have a plan. And you know what they say about plans!

Good plan, Mailman. I've never had a problem with a comealong that a little attention wouldn't fix. Sometimes frame fasteners get run down too tight at the factory and the drum gets pinched, a good slather of lube is usually needed, but I've never had one that wouldn't cooperate after a little TLC.

Agreed. I wouldn't try and go the 4000lb. rated max on it.... but for our little motors, should do just fine.

Heres is a simple and easy way which will keep your frame from being all chipped up. This was for install but the same setup could be used to remove it. 2x2 sheet of plywood, scrap 2x6, 3/8 threaded rod, some of those threaded nuts with the teeth on them which atach to the bottom of the 2x6, a few nuts &washers for the engine. Very controllable . Position the rods, attach the wood supports,tilt motor on side,either lift off or install the frame. A back saver.

Last edited:

Crazy seems like you could at least wipe the dirt off the motor if you're going to take pictures.

pamcopete

Ride.Enjoy.Life is Simple

To be used to secure a load from moving, like a tie down on a trailer or the bed of a pickup truck. The load is "dead" in the sense that it does not move.By the way, what the heck does that ad mean when it says that 4000 pound winch is “ For dead loads only. Not lifting”. Huh?

You have seen these on a trailer used to haul cars hence the need for 4000 lbs capacity.

Many of these types of ratchet devices do not have a way to gently release. If you use it to lift a load, such as an engine, you would have no way to gently lower the engine.

Last edited:

pamcopete

Ride.Enjoy.Life is Simple

Two 6 foot long 2 X 4's through the frame secured to the front and back of the engine with chains with one end of the 2 X 4's resting on a secretaries wheeled chair, lift the other end and gently move the engine out the side using the wheeled chair to carry the load. This method also provides leverage to reduce the weight that you have to lift.

Last edited:

I have my own way but as I said a couple of months back I will be doing the "Girl Method" when I strip the bike down and repaint the frame. My method always results in some chipping to the frame so I will not want that next time.

Similar threads

- Replies

- 3

- Views

- 668