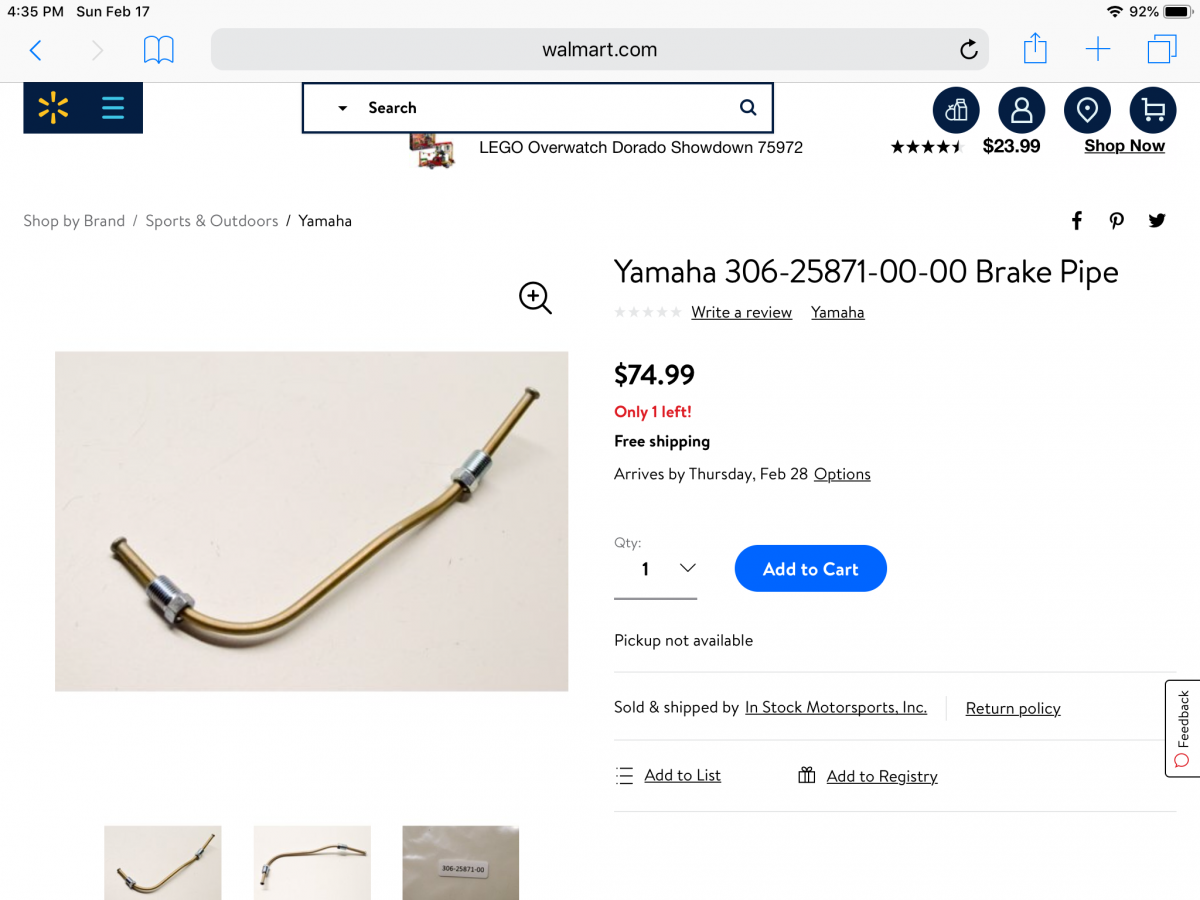

First an update on my brake line

. Then......

Pamco Ignition with E- Advancer installation.

I hopped in my Fiat this morning with brake line in hand , full of optimism and determined to come back home with something, anything to break this log jam I’ve reached. I went to......

A Brake shop.......they don’t do custom work

A local garage where all the guys are ASE certified and seem experienced..........Nope won’t do it

Two auto parts stores, just looking for a straight line that I could bend......... all the wrong sizes

A transmission shop.......they said sure, well maybe, not today, How much? I asked. Don’t know....depends ( big help)

So the search continues. 5Twins, you are absolutely right, for the cost of a new reproduction line, I could buy a tubing bender, flaring tool, tubing and fittings. But this is the first brake line I’ve ever had to make and honestly I can’t forsee ever having to make another another, I hate to buy all those tools and just have them sit unused.

The heck of it is, I’m not 100% confident that the steel line is the culprit here. All I know is that union leaks.

Moving on......

I needed to get some foward progress going again, so I decide to tackle a job that I knew I could complete with the remaining part of my day. And so ......

HERE IS MY PAMCO INSTALLATION

The first thing I did was decide where to mount my coil. I am going to mount it in the same location that the factory coils were located. I like to keep brackets simple, the mounting plate is just an aluminum plate with slotted mounting holes to allow back and forth adjustment in case I need to adjust for clearance. The stand offs I made from a galvanized pipe nipple ( cheap) cut to 25mm.

Then I installed the Pamco backing plate.

Then I installed the rotor on the advance rod and slid it through the cam.

And installed the advance mechanism replacement hub on the other end of the advance rod.

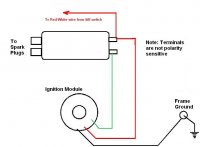

Then made all my wiring connections as per the Pamco website instructions. All ground points on the frame were shined to bare metal with a Dremel.

After that I needed to make up the spark plug wires. I bought 4’ of copper core silicone wires from an eBay seller,

And a set of NGK suppressor caps.

And installed.

So the Pamco is now installed and awaiting start up and final timing set. I do have one question at this point.

The ignition wires from my original wiring. I know that the gray and orange wires are not used, the red wire w/ white stripe goes to one side of the coil.

Coming from the wiring harness was the red wire w/ wht stripe and it was joined to a brown wire in the same multi plug.

I did not use that brown wire. I wrapped up the gray and orange and that brown wire and tucked them away.

Should I have done something else with the brown wire?

Lastly, I installed my breather tubes, just loosely for now until I fine tune the routing.

I still have to figure out my front brake riddle but it felt good to make some progress today.

Until next time,

Bob

. Then......Pamco Ignition with E- Advancer installation.

. Then......Pamco Ignition with E- Advancer installation.