sseres

XS650 Junkie

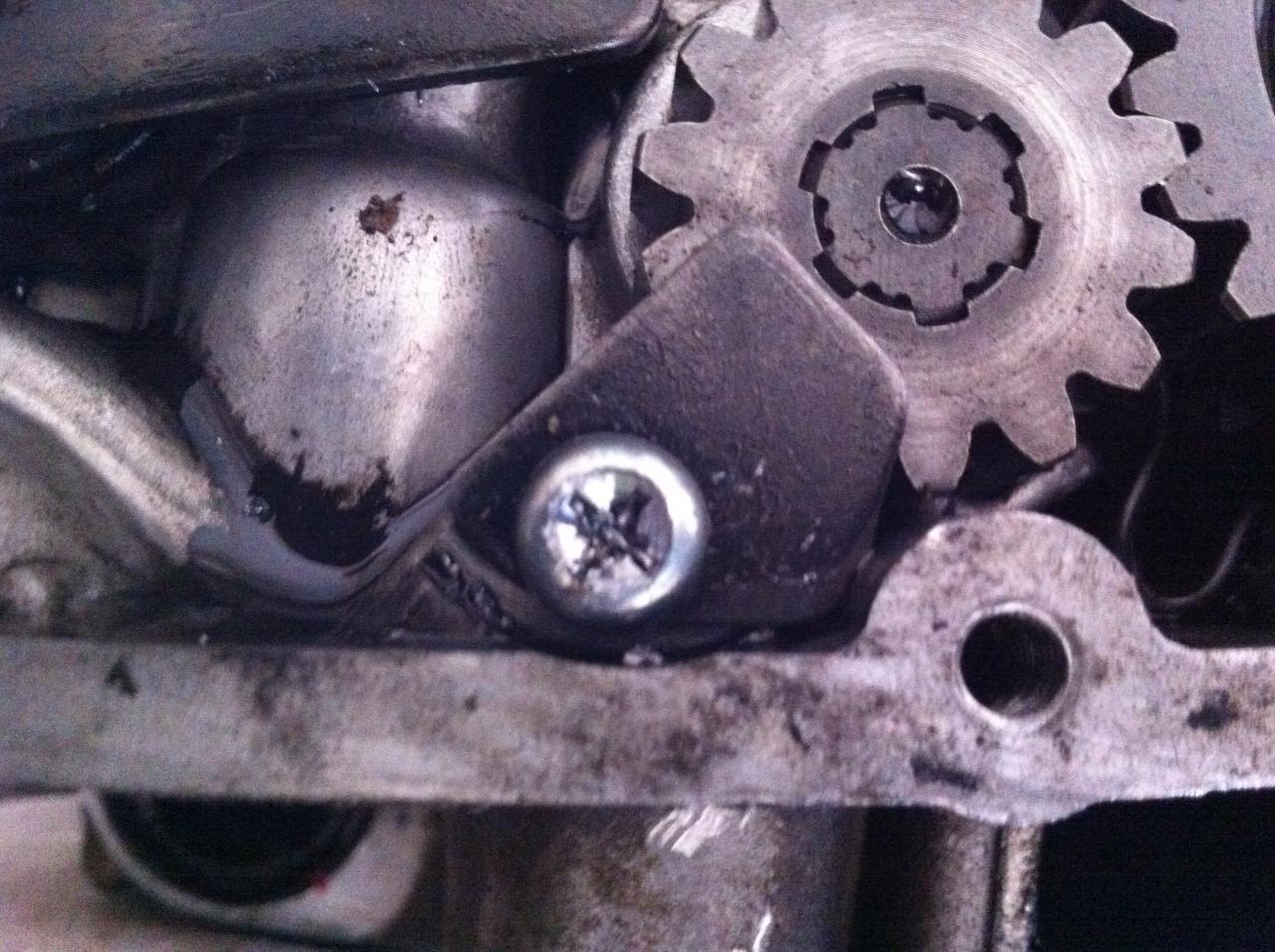

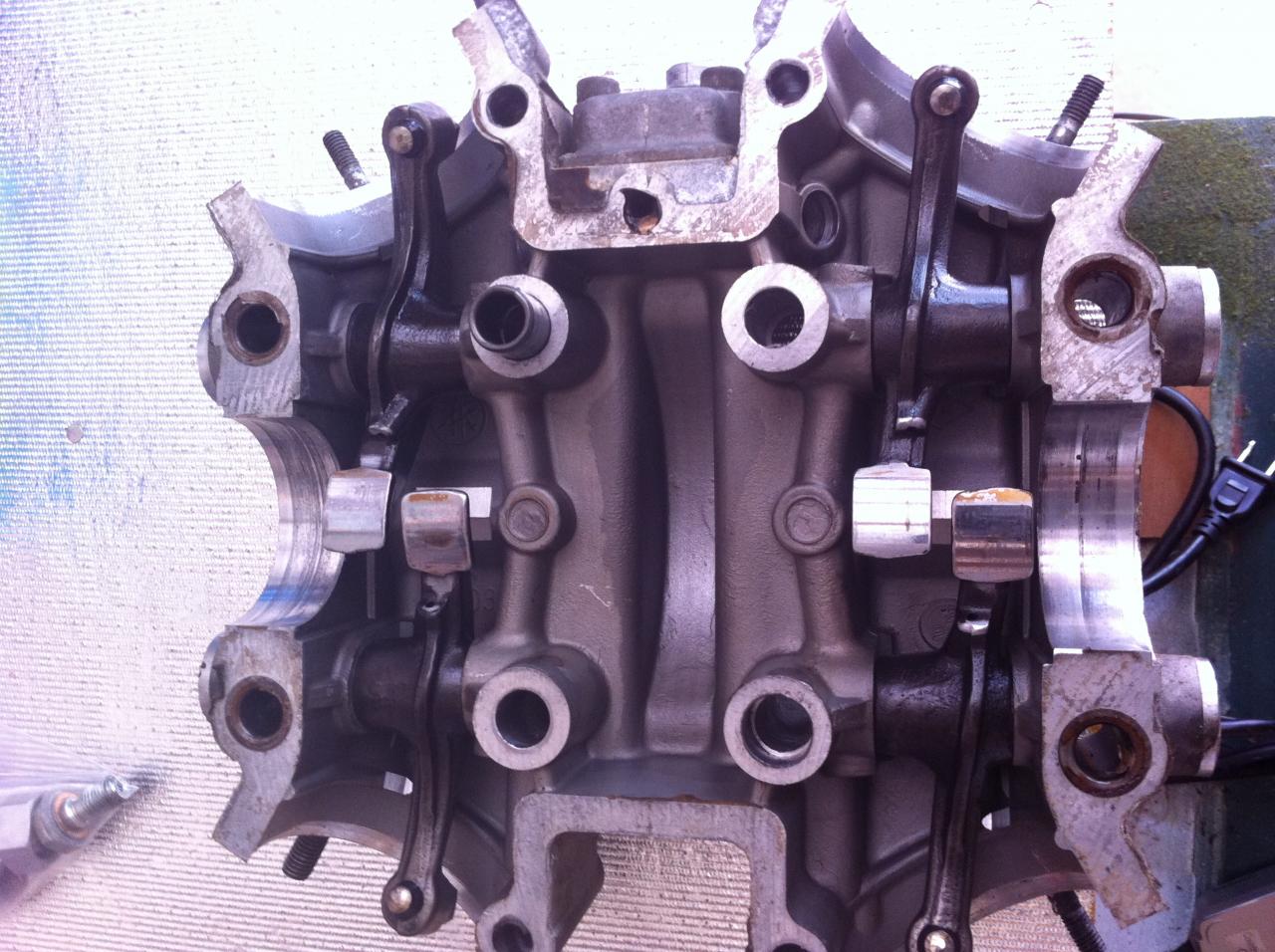

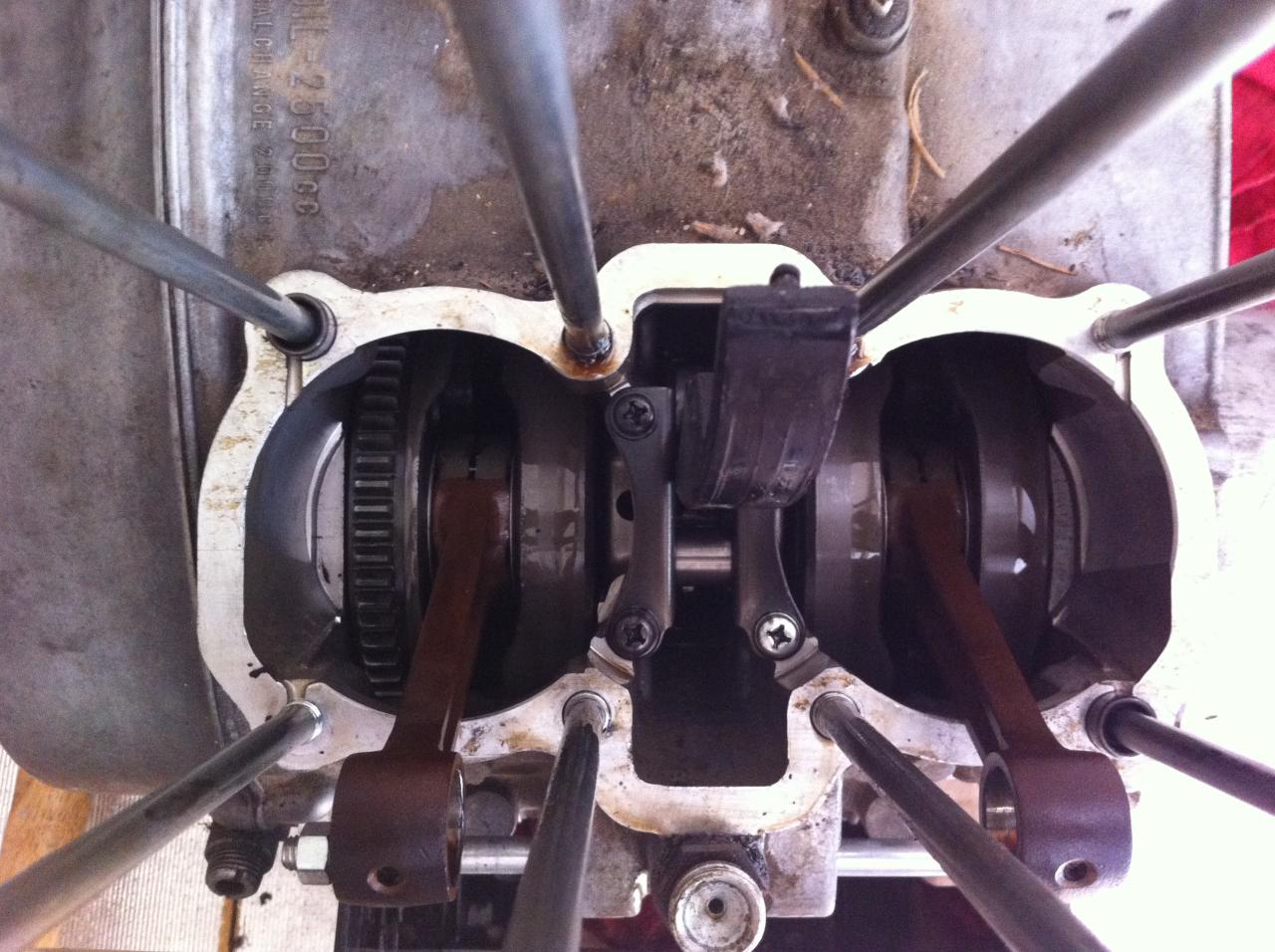

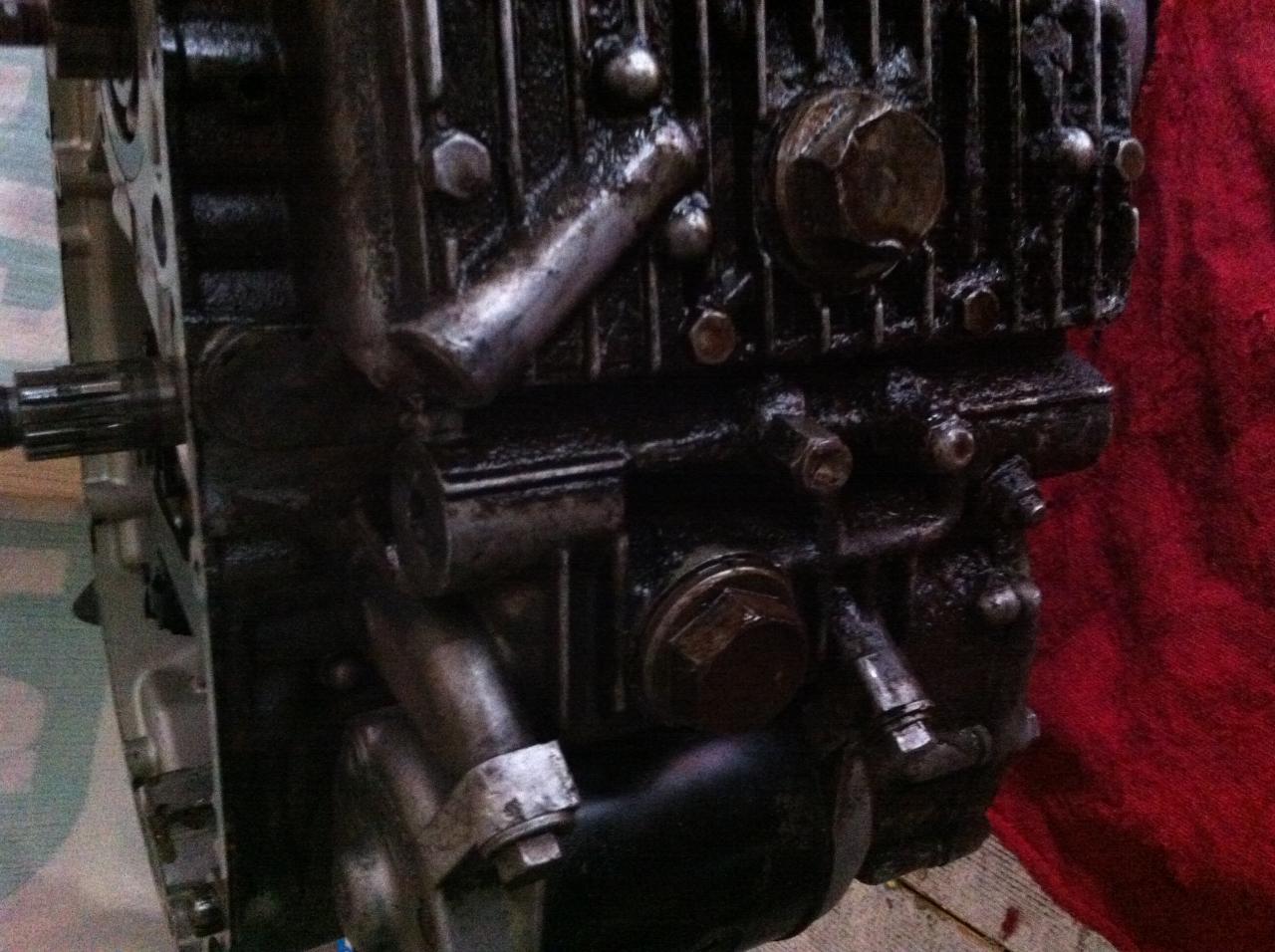

after having been talked down from disassembling my working engine, a friend talked me into finding a dead engine to go nuts on. This is my first attempt at ever rebuilding anything bigger than my son's Star Wars Legos.

Within 1 hour of posting a wanted here in the forum, I got a note from someone not too far from here with what I was looking for. 100psi compression and dirtier than you can imagine. Very nice guy with amazing land and a hoist in his garage. Now that's an awesome tool!

So, anyway, here's the goal, and then I'll swap it out with the engine in my bike (the one that runs):

Clean, clean, clean, get it blasted then maybe paint?

polish up covers

new gaskets, rings and anything wornout looking.

Rephase (planning on sending crank and cam shafts to Hugh)

so this includes the 277 PAMCO system

clutch screws replaced with Mike's hex bolts

considering PMalternator (probably only if I can get someone to buy the old one)

5th gear upgrade

Am I missing something?

Anyway, presenting... the engine!

Within 1 hour of posting a wanted here in the forum, I got a note from someone not too far from here with what I was looking for. 100psi compression and dirtier than you can imagine. Very nice guy with amazing land and a hoist in his garage. Now that's an awesome tool!

So, anyway, here's the goal, and then I'll swap it out with the engine in my bike (the one that runs):

Clean, clean, clean, get it blasted then maybe paint?

polish up covers

new gaskets, rings and anything wornout looking.

Rephase (planning on sending crank and cam shafts to Hugh)

so this includes the 277 PAMCO system

clutch screws replaced with Mike's hex bolts

considering PMalternator (probably only if I can get someone to buy the old one)

5th gear upgrade

Am I missing something?

Anyway, presenting... the engine!

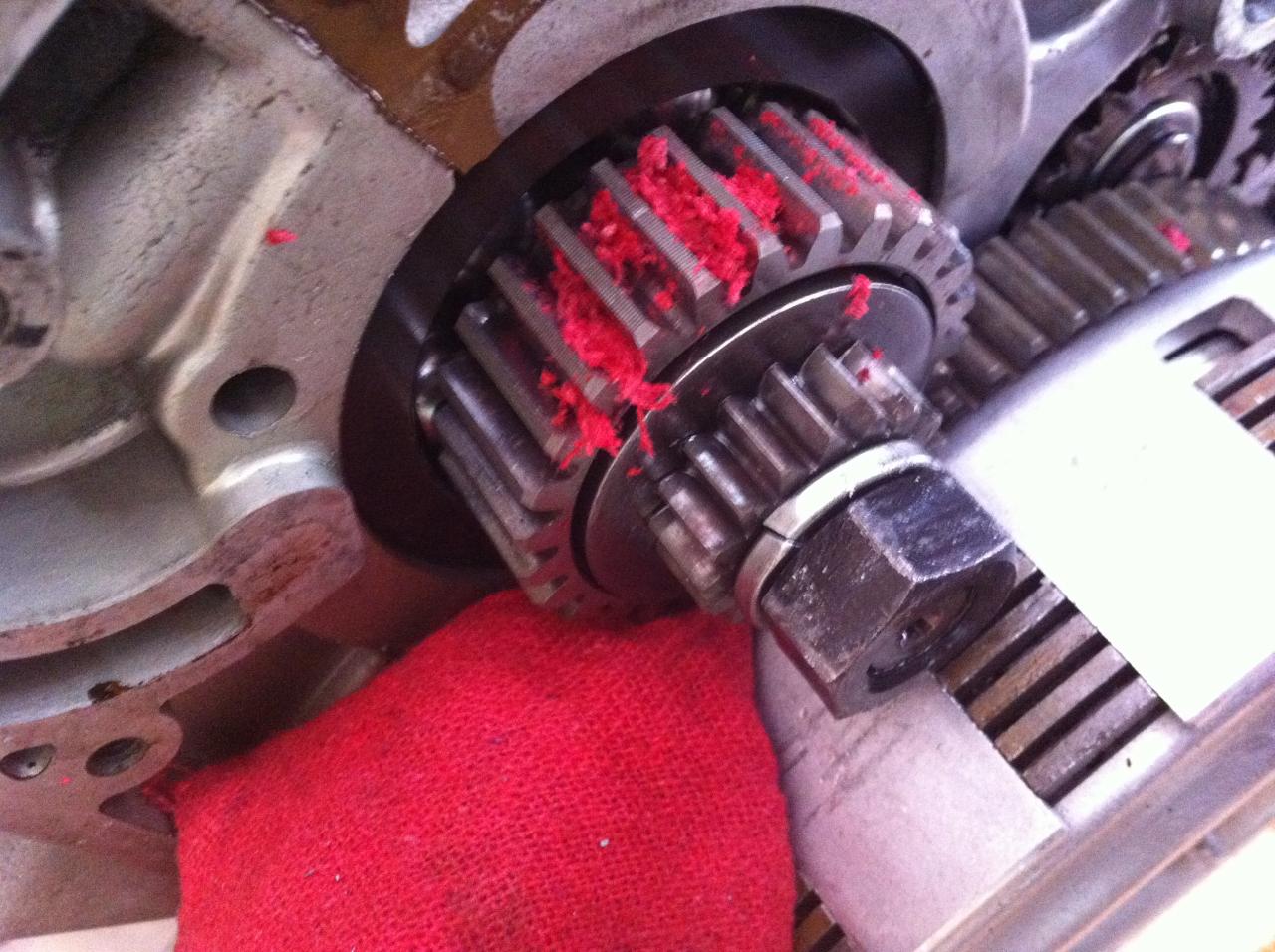

I looked and looked but just didn't see what I was missing. Then, it was kid's bed time and starting to get dark so I had to wrap it up for the night. Nuts! (get it?

I looked and looked but just didn't see what I was missing. Then, it was kid's bed time and starting to get dark so I had to wrap it up for the night. Nuts! (get it?  )

)