alfredo

1978 xs650 Special

btw, impeccable wiring amigo.

btw, impeccable wiring amigo.

Not bad man! Came out pretty decent. Lot of sanding between coats/colors?

+1, I would guess he is an industrial electrician, looks pro.

so we'll just have to see once the engine is back in...

so we'll just have to see once the engine is back in...

Damn man, you don't waste any time!

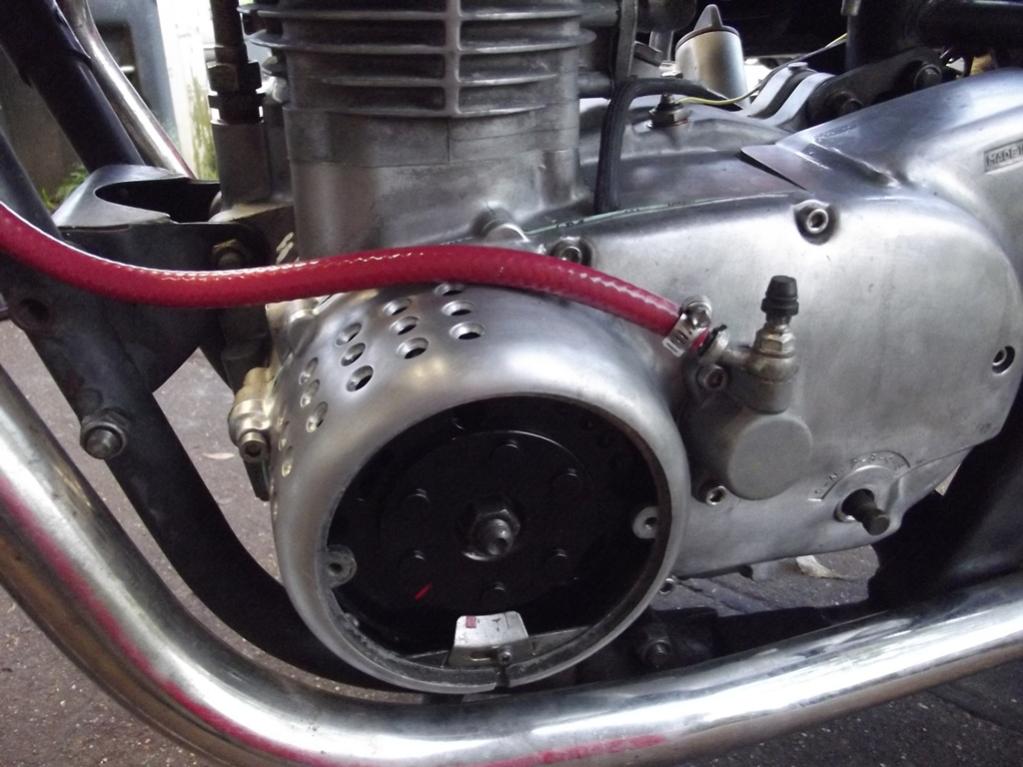

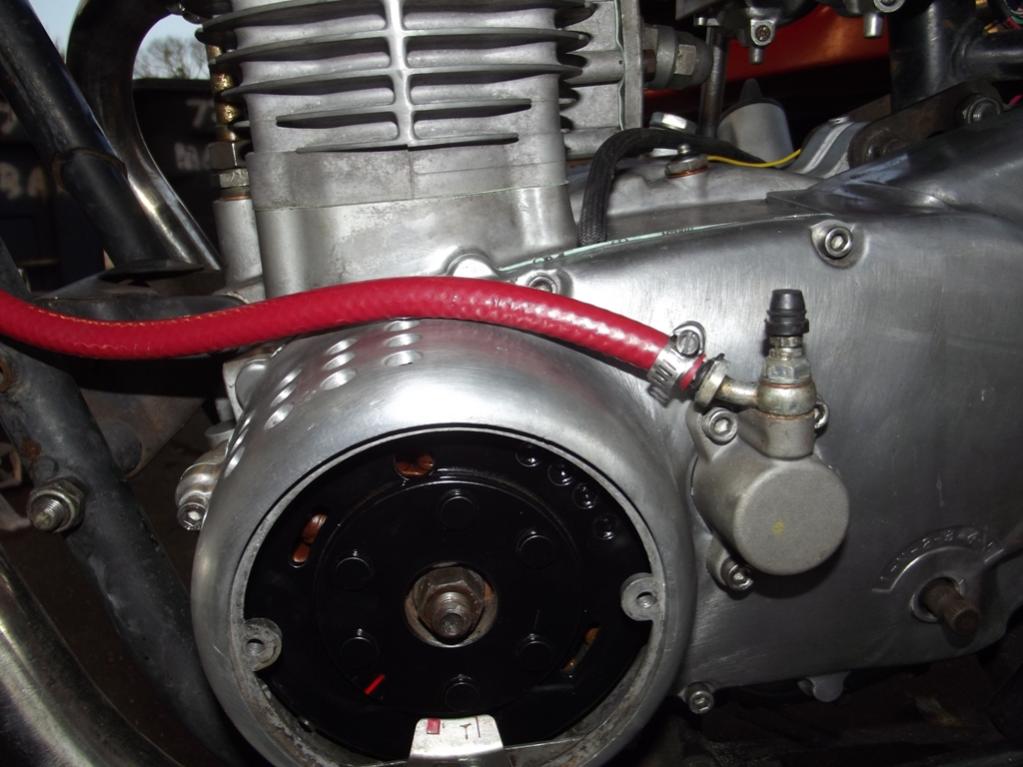

I have the same clutch slave, so I'll chime in too... Part of makes the Aprilia/Rotax slave small and neat is how the bleeder is integrated into the banjo. No physical reason you couldn't mount it in any other arbitrary location (so long as the screw lugs don't hit the alternator bulge), but it would be a real pain to bleed. If you're thinking that you could remove the slave for bleeding: that's possible, but impractical, as being mounted into the sidecover is what retains the piston... when removed from the sidecover, the piston is free to pop out when you pump the lever, unless the retainer is somehow (temporarily) bolted/clamped to the slave body.I have seen a couple of posts on the hyd clutch mod, is there any particular reason that you install the slave with the hydraulic fitting upwards? I realise that it makes it easier to bleed in situ, but if it where on the bottom it might look a little neater?

Mounted upright makes it more than just "easier"; it makes it practical and dead-simple to bleed.

, probably would have started on the first with the choke on. Checked for any oil leaks

, probably would have started on the first with the choke on. Checked for any oil leaks  none found. Listened for any ticks or odd sound and she sounded SWEET! Checked the timing and had to do a double take, it was dead on after setting the Pamco in the middle of the upper adjustmet slot. Shut her down and let her cool down for just a bit while I basked in the glow of a job well done. Hooked up my manometer and started her back up, had to shut her down real quick as the right side was pulling up quickly (just goes to show how bad it was before) made a few short runs until I got the carbs close to being synced so that I could let her run long enough to get the carbs synced and steady. I was going to adjust the fuel mixture screws using the "dead cylinder" method but the internet was not cooperating and it got dark. So there is the progress as of now, all in all not a bad day.

none found. Listened for any ticks or odd sound and she sounded SWEET! Checked the timing and had to do a double take, it was dead on after setting the Pamco in the middle of the upper adjustmet slot. Shut her down and let her cool down for just a bit while I basked in the glow of a job well done. Hooked up my manometer and started her back up, had to shut her down real quick as the right side was pulling up quickly (just goes to show how bad it was before) made a few short runs until I got the carbs close to being synced so that I could let her run long enough to get the carbs synced and steady. I was going to adjust the fuel mixture screws using the "dead cylinder" method but the internet was not cooperating and it got dark. So there is the progress as of now, all in all not a bad day.