New cyls, pistons, rings. Rings right side up and clocked. Valves don't leak. Head gasket looks ok. Compression 75 instead of 175+. No bad noises. Tappets set right. Passing enough oil to smoke and wet the plugs.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oil in cylinders

- Thread starter Stoop22kid

- Start date

Stoop22kid

XS650 Addict

More to come tomorrow eveningNew cyls, pistons, rings. Rings right side up and clocked. Valves don't leak. Head gasket looks ok. Compression 75 instead of 175+. No bad noises. Tappets set right. Passing enough oil to smoke and wet the plugs.

Stoop22kid

XS650 Addict

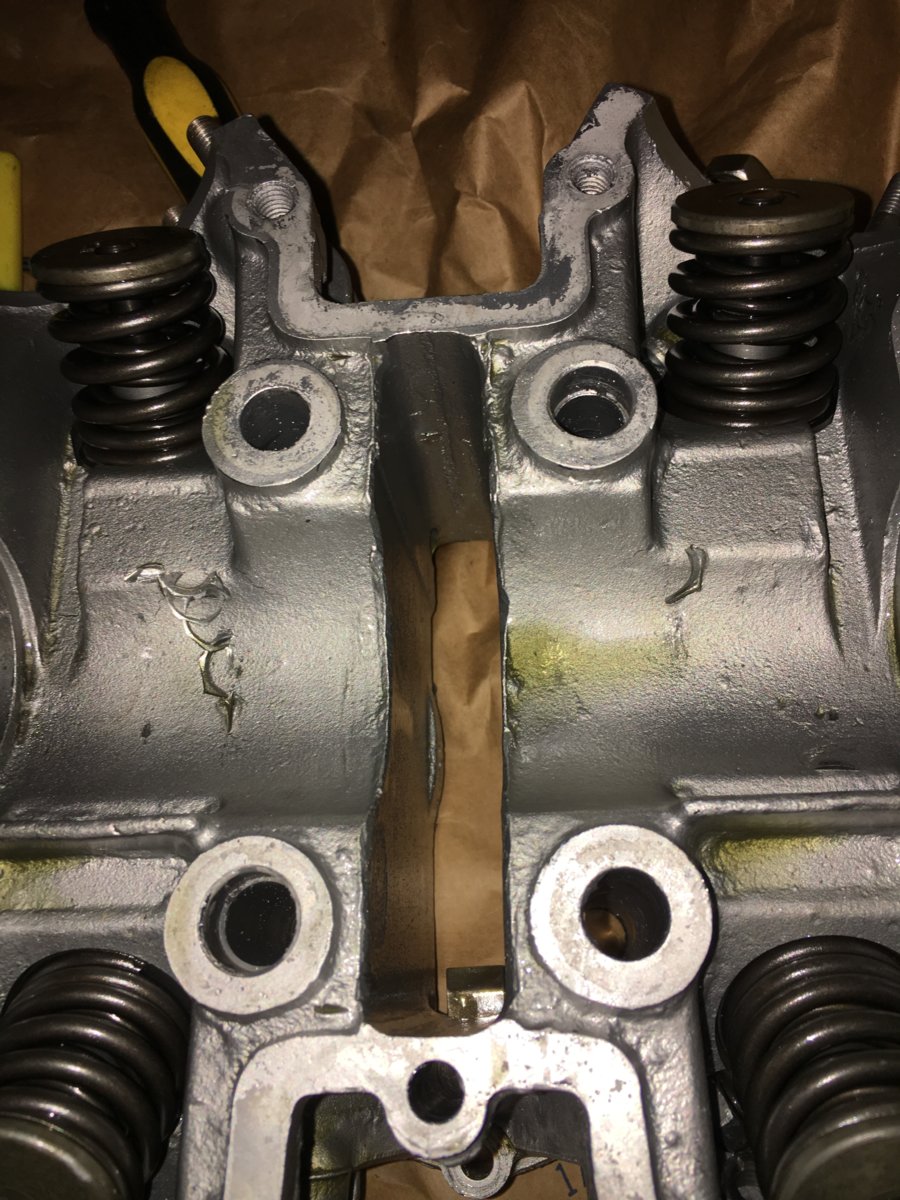

So let me take y'all through my morning.....I get off work at 5 am. Have a nice relaxing 20 minute drive home. Take my lunch box inside and grab a beer and head to the garage. Take off my gas tank. I take the cam bearings off and fight the chain a little bit but it finally lets the cam slide out. Almost drop the cam chain but I caught it in time and put the handle of a hammer through the chain to hold it. I life the head up as much as I can while still holding the chain then place a knife under the head and between the chain to hold it from falling into the cases. I get the head off and something catches my eye (poorly lit garage) so I take the head over and look at it closer under the better lighting. And I see multiple gouges in the head where the cam sits...

so of course my heart drops thinking the my cam is going to be toast. I go get the cam to check it out and there's not a scratch on it what so ever. So I'm a little relieved and go back to lookin at the head. Other than this the top of the head looked ok. So I flip it over and heard something fall on the ground. I look down and this is what I find.

so of course my heart drops thinking the my cam is going to be toast. I go get the cam to check it out and there's not a scratch on it what so ever. So I'm a little relieved and go back to lookin at the head. Other than this the top of the head looked ok. So I flip it over and heard something fall on the ground. I look down and this is what I find.

looks to be a 10mm nut. No idea where it came from. No idea how it got there. No idea how in the world I never noticed it was there. No idea how I never heard any grinding. So I guess my next step is to file down where the gouges are, order my new parts, and get this thing back together.....or is the head toast? Here's some more pictures that I took so tell me what y'all think

looks to be a 10mm nut. No idea where it came from. No idea how it got there. No idea how in the world I never noticed it was there. No idea how I never heard any grinding. So I guess my next step is to file down where the gouges are, order my new parts, and get this thing back together.....or is the head toast? Here's some more pictures that I took so tell me what y'all think

Stoop22kid

XS650 Addict

Wow.....figured out what it was.....tappet nuts. Anyone want to kick me in the balls for this stupid mistake and make me feel better?

It's good that you found that stray nut but I don't see how it could relate to all the excess oil in your cylinders. It was above and isolated from them. I think you still need to examine your bores, rings, and pistons. Your pics seem to show a lot of vertical scraping on the bores. That's something you often find on a high mileage, worn motor but I wouldn't expect to see it on one with only a few hundred miles.

Hyde

XS650 Addict

Agree with 5Twins, it's great you found the nut but that does not even begin explain the low compression. The vertical cylinder scoring is concerning. A total inspection of the entire top end is in order if you've got'er apart already. What's up with the carboned headgasket ring & cylinder sleeve? It looks like that thing was off-center and pushed back a few milimeters on both sides.

member3480

RICH

That sure looks like scraping on the side walls. Did you loose a wrist pin clip or forget to set it in the groove. I have had race motors do that when the Teflon pins wear down. I would really look at those rings good. I agree that it looks like a motor with a lot of miles. I have a set I just took off the bike with leaking oil and the marks are so bad it has to be bored.

Hyde

XS650 Addict

Heh I'd be also interested to know what's on the sump magnets and case filter at this point.

Stoop22kid

XS650 Addict

Yeah I can feel the scraping with my finger.....trying to pull the jugs as I type

Stoop22kid

XS650 Addict

Everything on the pistons are intact. No broken rings and the clips are still in. The scraping is only on the front and back of the cylinders from where the side skirts of the pistons are rubbing. There are scrapes on the pistons as well.

Did the ring gaps get set to specification during assembly?

I don't see any cross hatching on the cylinder walls...........................cylinders were never honed???

Need to have the piston diameter and cylinder diameter measured very carefully, to see if the clearance is correct.

A Mikesxs product......................quality of workmanship is always suspect.

Need to have the piston diameter and cylinder diameter measured very carefully, to see if the clearance is correct.

A Mikesxs product......................quality of workmanship is always suspect.

Does the piston to cyl clearance look excessive to anybody else? Less than .003" is allowed in a new stock motor. With the right pistion pic I think I can actually see the top ring gap at the bottom of the pic. Too much clearance would have the piston scraping up the wall. Not to mention low compression.

Last edited:

Yes, I was thinking the same thing. Maybe its the picture, but the piston to cylinder clearance looks large to me.

Stoop22kid

XS650 Addict

Ok guys here's the plan. I'm going to do a complete top end rebuild.....hopefully right this time. I'm still learning as I go and I greatly appreciate your guys help. I've got a spare set of rings I'm going to gap correctly and hone the cylinders to get rid of the scratches. Thank you guys so much.

Hyde

XS650 Addict

Dude don't just start throwing $$$ at it until you know exactly what's wrong. Start measuring and recording it on paper. Throw it back here and these awesome gents can walk ya through.

Before rushing into a rebuild just remember that it has been pointed out that the piston clearance looks too large. This is the gap between the piston and the cylinder wall. It has nothing to do with the ring end gaps. This observation may just be an optical illusion in your photos but if true then honing and new rings will not be the answer because the pistons maybe too small.

It is suggested you have the cylinder bores measured accurately along with the diameter of the pistons. The average bloke will not usually have the correct equipment to do this. You could take the cylinders and pistons to an engine rebuilder and ask them to check for you........

...... or for now just see what size feeler gauge will fit between the piston and the cylinder wall. If you do not want to remove the rings then I suggest making the measurement at the bottom of the piston. Report your findings and see what the very experienced engine rebuilders on this forum suggest.

It is suggested you have the cylinder bores measured accurately along with the diameter of the pistons. The average bloke will not usually have the correct equipment to do this. You could take the cylinders and pistons to an engine rebuilder and ask them to check for you........

...... or for now just see what size feeler gauge will fit between the piston and the cylinder wall. If you do not want to remove the rings then I suggest making the measurement at the bottom of the piston. Report your findings and see what the very experienced engine rebuilders on this forum suggest.

Right. See if you can work larger than a .006" feeler gauge between the piston and the cylinder. Top or bottom or both. If you can, you need to get your money back or get a replacement. It's something over $750, isn't it? If there's too much clearance honing will destroy your evidence and probably wouldn't do anything to help you in any case. They were honed originally; it's the final step of boring.