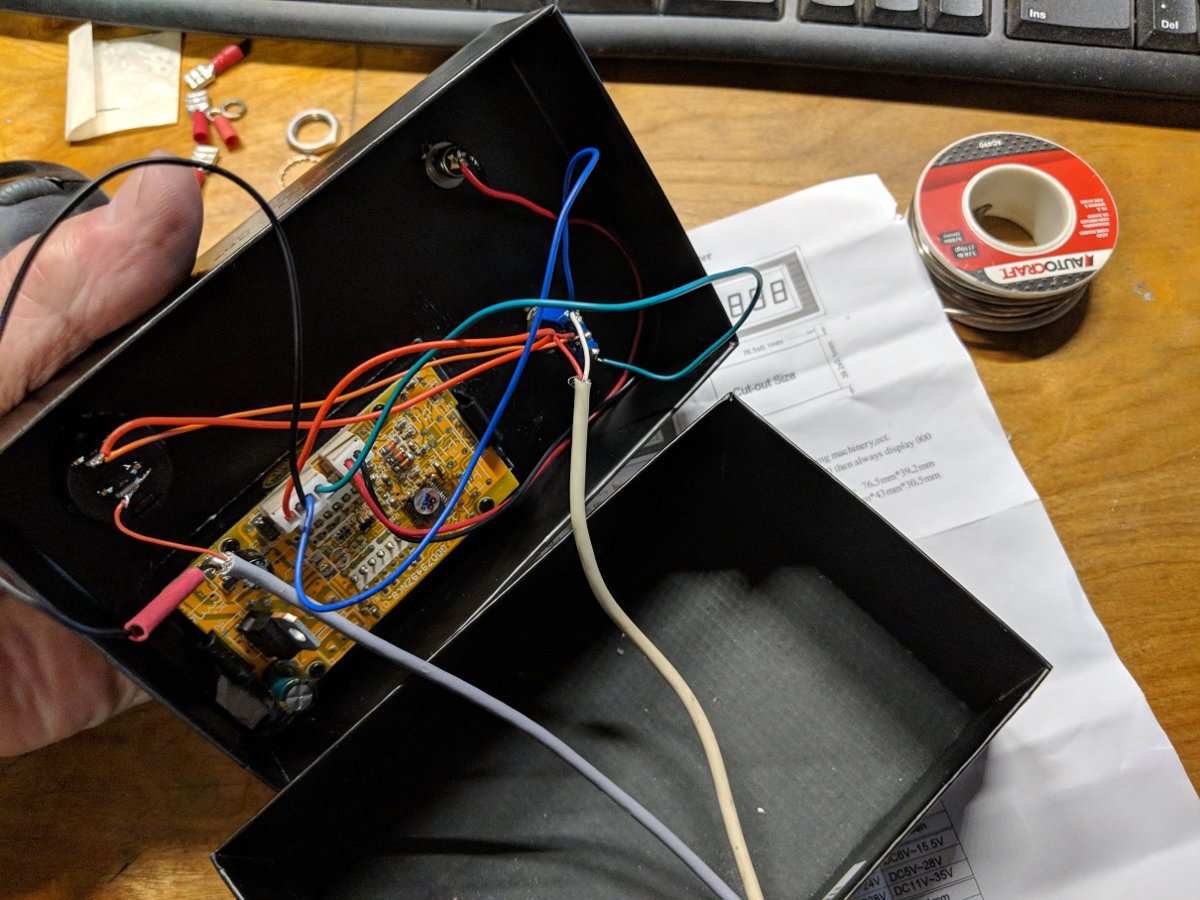

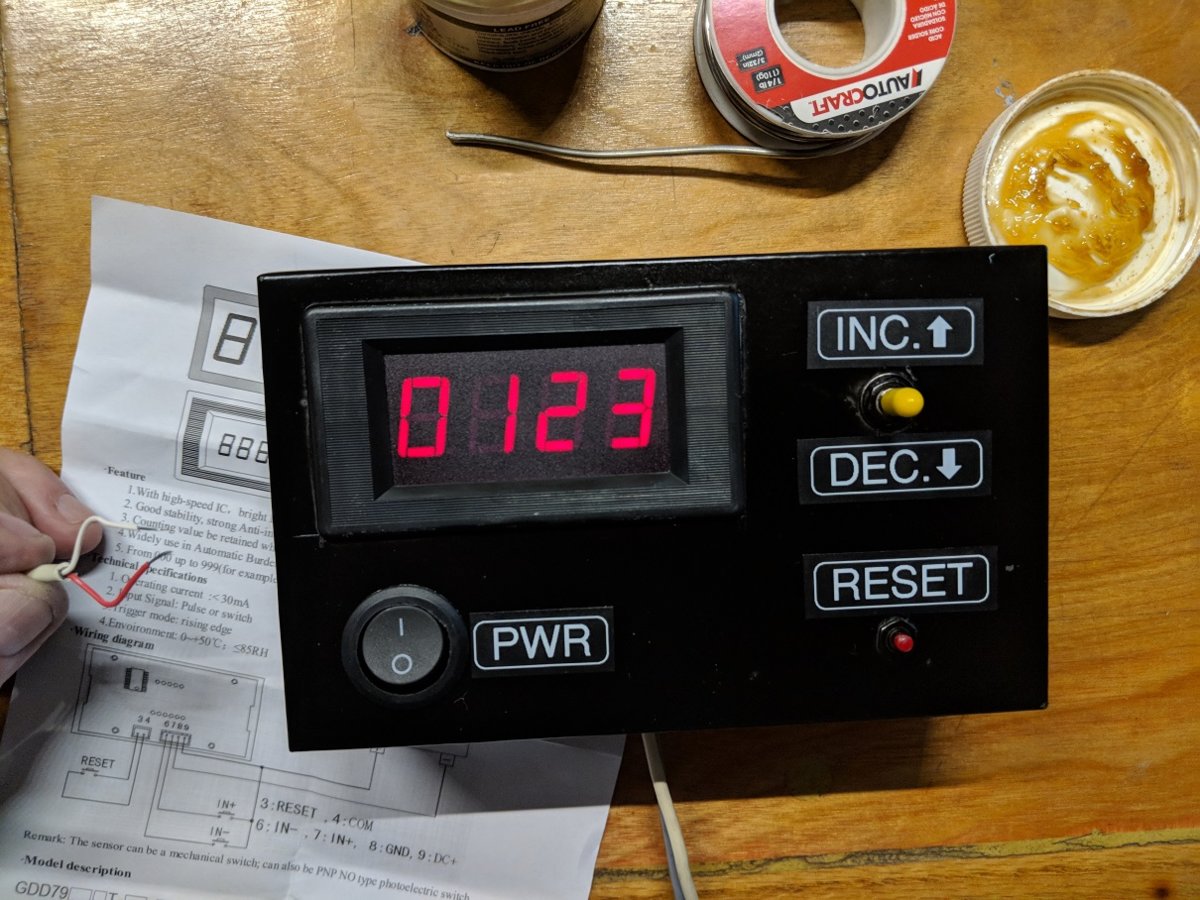

A week or so back, I took a cardboard box and about ten bucks worth of Chinese stuff and made a rotation counter.....

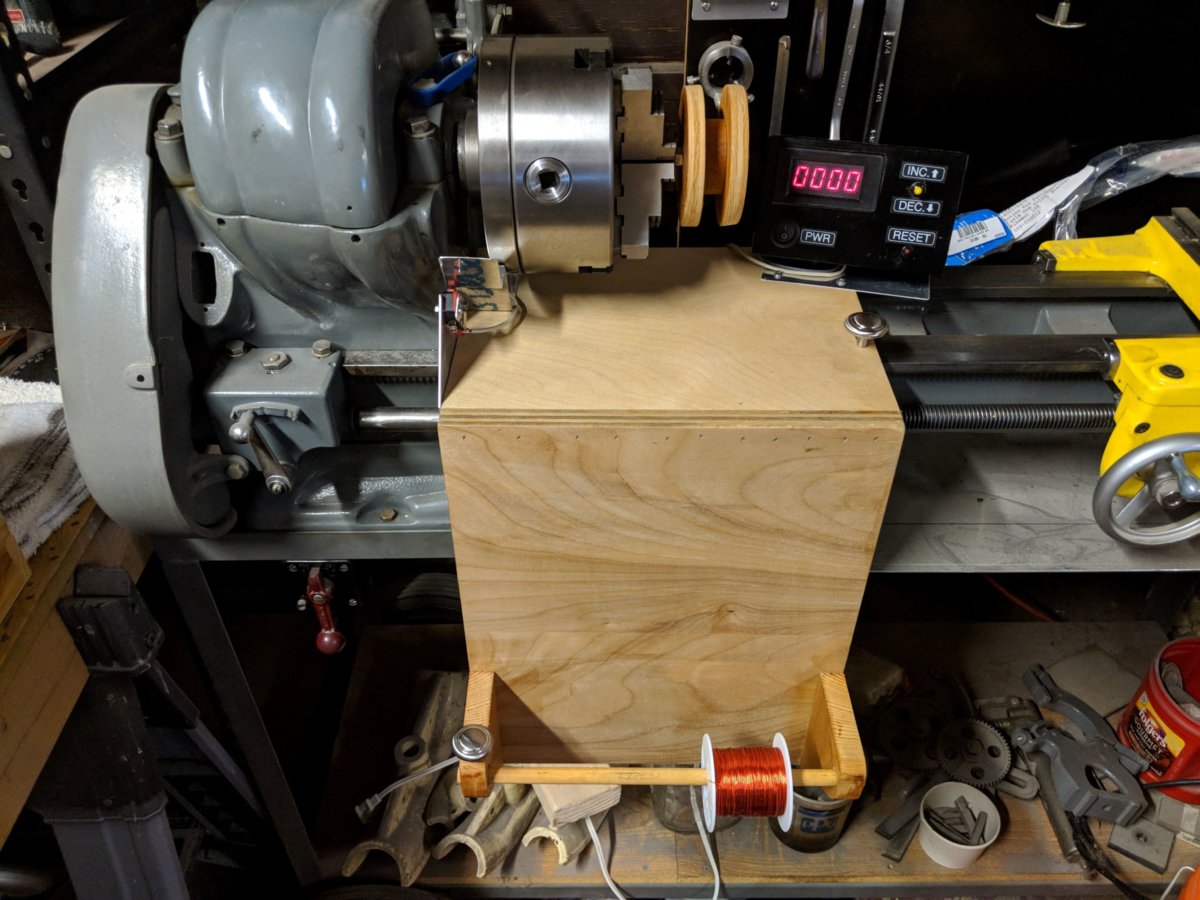

Today I made the rest of the wire coil winder/maker thingey.... I'm using the Atlas to make the coils, so I wanted something that was easy to install and remove. Glued and nailed two pieces of 3/4 ply together and added a simple angle to the back of it to grab the bed of the Atlas.

The drawer knob is to lock it in place. Installed another aluminum angle off the right side to install the counter on.

.

Added a spool holder to the bottom.

..... and a micro-switch for counting......

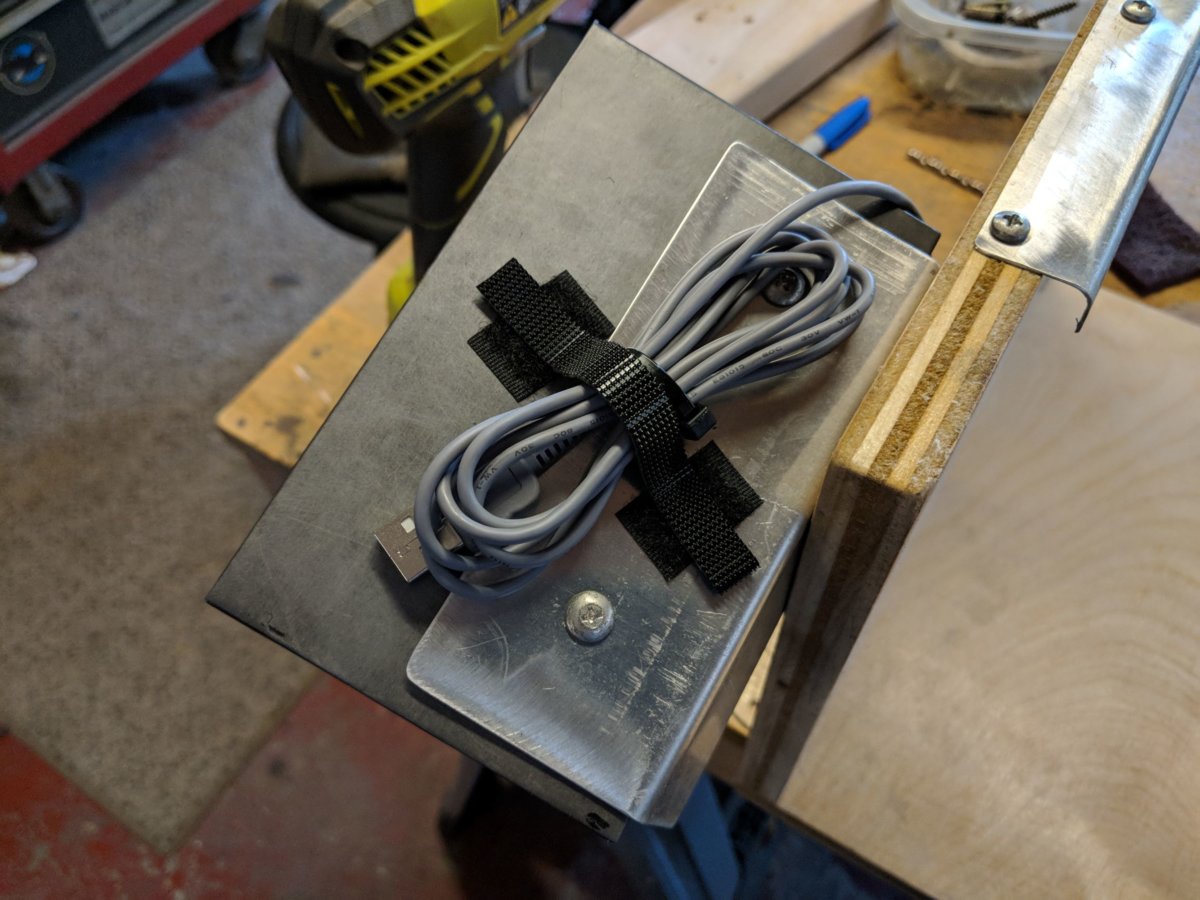

I was powering the counter from a USB charger but today I installed a 9v battery holder in the box. I went ahead and left the charger cord hooked up just in case... and used velcro to hold it.

It takes about 15 seconds to install or remove it.

Did a quick video of it in operation. The Atlas was at it's lowest speed. I'll play with the speed as I learn. I think before I wind any wire, I'm gonna make a foot switch addon for the Atlas so I have both hands free to tension and guide the wire. I'm guessin' the switch mechanism clinking is gonna get on my nerves.... so I'll order a hall effects switch for it....

Today I made the rest of the wire coil winder/maker thingey.... I'm using the Atlas to make the coils, so I wanted something that was easy to install and remove. Glued and nailed two pieces of 3/4 ply together and added a simple angle to the back of it to grab the bed of the Atlas.

The drawer knob is to lock it in place. Installed another aluminum angle off the right side to install the counter on.

.

Added a spool holder to the bottom.

..... and a micro-switch for counting......

I was powering the counter from a USB charger but today I installed a 9v battery holder in the box. I went ahead and left the charger cord hooked up just in case... and used velcro to hold it.

It takes about 15 seconds to install or remove it.

Did a quick video of it in operation. The Atlas was at it's lowest speed. I'll play with the speed as I learn. I think before I wind any wire, I'm gonna make a foot switch addon for the Atlas so I have both hands free to tension and guide the wire. I'm guessin' the switch mechanism clinking is gonna get on my nerves.... so I'll order a hall effects switch for it....

Last edited: