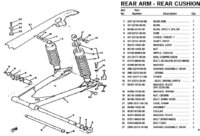

installing a new ushing (swing arm Bolt tube) Swingarm Pivot Bolt (Shaft) & bushings on my rear end

Bushing installed into the swing arm just fine

the shaft fits into the bushings just fine

Now when install the bolt into the pivot bolt shaft isn't going well. Way to tight a fit into it. I realize they have to work as one but I'm 100 heavy hammer strikes into trying to drive the bolt through and only gained about 2" inches. Yes I'm using a brass drift between the hammer and bolt. Way way too tight. The original one was a bit*^h to get out but not like this.

This is way to tight a fit. The pivot bolt shaft has 4 holes in it for grease to come through and those weren't cleaned up. I used a rat tail file to clean them up in anticipation of driving the bold through.

Any ideas here?

Bushing installed into the swing arm just fine

the shaft fits into the bushings just fine

Now when install the bolt into the pivot bolt shaft isn't going well. Way to tight a fit into it. I realize they have to work as one but I'm 100 heavy hammer strikes into trying to drive the bolt through and only gained about 2" inches. Yes I'm using a brass drift between the hammer and bolt. Way way too tight. The original one was a bit*^h to get out but not like this.

This is way to tight a fit. The pivot bolt shaft has 4 holes in it for grease to come through and those weren't cleaned up. I used a rat tail file to clean them up in anticipation of driving the bold through.

Any ideas here?