As I was making the entry hole cutter tool, a thought kept pinging in the back of my head. This thing looked familiar, then it dawned on me:

I was re-inventing the faucet seat recutting tool !!!

Found the Mintcraft #T1533L repair tool, with the 9/16" cutter head, ordered 2.

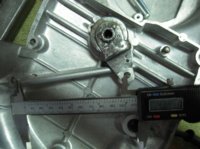

Now, just need to make the 4" long pilots for it...

I was re-inventing the faucet seat recutting tool !!!

Found the Mintcraft #T1533L repair tool, with the 9/16" cutter head, ordered 2.

Now, just need to make the 4" long pilots for it...