Looking good Pete, I can't wait to see the final chapter of this story!

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Thread...Special to Cafe Bike

- Thread starter MaxPete

- Start date

OK - here are the lessons learned on the starter hairpin job:

Thanks very much to Gary, YamaDude, 2M and 5T and everyone else who helped along with info, ideas, suggestions and encouragement. This really isn't a very difficult job (none of them are really...) - but it does take a little patience and some special tools to do it properly.

NEXT TASK: getting the bike running reliably, safely and well - before the conversion tasks commence like the tank swap, the new cafe seat, the 18" rear wheel, the double disk conversion and the final paint. Stay tuned and watch this space!

Cheers,

Pete

- I asked Gary and he said that he can do this job in two hours. This was my first time and it probably took me five hours - but the next time, two hours would be a reasonable estimate.

- Lay the bike over on its left side - this task is much easier if gravity is helping you assemble things rather than having them fall all over the floor.

- Get a GOOD manual that shows a detailed exploded view of the entire clutch assembly - WITH the thicknesses of the various shims and washers.

- BE SURE to push the kickstarter shaft IN while you are removing the RH side engine case-cover.

- Once you have the RH engine case-cover off - carefully remove all traces of the used gasket from the sealing surfaces.

- Get one of those Vessel #3 JIS IMPACTA impact screwdrivers - unless you know that your clutch screws have been replaced with Allen head screws.

- Get a buzz-gun or air impact gun & the exact sized socket to remove the big clutch centre nut.

- Get a fish or luggage weighing scale to test the slip force of the hairpin on gear #4.

- Test all hairpins BEFORE installing them - regardless of where you got the part

- DO NOT install any hairpin that slips at less than 6 lb but higher is better.

- Get a digital vernier caliper to measure the clutch parts when you have it apart.

- XS650 clutches are very tough - but you might as well check the thickness of the clutch plates, length of the six clutch springs and also inspect the condition of the anti-rattle springs on the backside of the clutch basket - because you'll have the entire clutch apart during this job.

- Have a supply of clean rags handy to cover the parts as you remove them and also to cover the engine while you are working on the clutch.

- Put the bike in gear and use the rear brake to lock the clutch when removing or installing the clutch centre nut and clutch holding screws. The MikesXS clutch holding tool is a waste of money and will fold-up like a pretzel and make a fetching lawn ornament.

- Get a torque wrench with the correct range for the clutch centre nut (47 ft-lb) and holding screws (7 ft-lb). This means a big & a small wrench.

- BE SURE to install the little top-hat clutch pusher piece BEFORE you put the clutch plates, the inner member and six holding screws back on.

- Get a new RH case-cover gasket & your favourite gasket goo (I used Hylomar Blue - looks really trick oozing out around the edge of the engine case).

- Torque everything - these are highly loaded, very precisely made assemblies and things will go wrong if you skip steps or are sloppy with the work.

Thanks very much to Gary, YamaDude, 2M and 5T and everyone else who helped along with info, ideas, suggestions and encouragement. This really isn't a very difficult job (none of them are really...) - but it does take a little patience and some special tools to do it properly.

NEXT TASK: getting the bike running reliably, safely and well - before the conversion tasks commence like the tank swap, the new cafe seat, the 18" rear wheel, the double disk conversion and the final paint. Stay tuned and watch this space!

Cheers,

Pete

Last edited:

Good to hear that you got it all back together just fine and that the clutch is working as it should. Thats a good feeling.

And you got all the photos to fit in place, just where they should be !

I imagine you were a bit bleary-eyed by 1:21 AM.

I would have followed along, but I installed carpeting yesterday in intense heat, and collapsed to the bed at 9:30.

SO, your tension reading of only 6.5 on the Mikes repair kit was disappointing, and something they should be informed about, IMHO. I got 11 pounds on mine. So, this means that this item is inconsistent in quality. Does feedback to Mikes matter? I can say that I recently told them that their info re the manual petcock for later model XS's was misleading, and in response they completely re-wrote their description on that webpage.

Your photo essay is good, especially covering the little split washer well, which the tech article doesn't, as I recall. But the existing tech article does include the good suggestion of stacking the clutch plates in a particular manner so as to facilitate the separation of the plates from the cage, smoothing the cage contact points (if needed), and the suggestion I've made of measuring the springs and re-inserting them in a balanced manner around the "circle".

BTW, I have never encountered a RH leak by using just a well-greased, new gasket on the case, and copper washers on the screws that are below the oil line.

Looking forward to the rest of your build.

Hope you have access to good coffee up there in Windsor.

And you got all the photos to fit in place, just where they should be !

I imagine you were a bit bleary-eyed by 1:21 AM.

I would have followed along, but I installed carpeting yesterday in intense heat, and collapsed to the bed at 9:30.

SO, your tension reading of only 6.5 on the Mikes repair kit was disappointing, and something they should be informed about, IMHO. I got 11 pounds on mine. So, this means that this item is inconsistent in quality. Does feedback to Mikes matter? I can say that I recently told them that their info re the manual petcock for later model XS's was misleading, and in response they completely re-wrote their description on that webpage.

Your photo essay is good, especially covering the little split washer well, which the tech article doesn't, as I recall. But the existing tech article does include the good suggestion of stacking the clutch plates in a particular manner so as to facilitate the separation of the plates from the cage, smoothing the cage contact points (if needed), and the suggestion I've made of measuring the springs and re-inserting them in a balanced manner around the "circle".

BTW, I have never encountered a RH leak by using just a well-greased, new gasket on the case, and copper washers on the screws that are below the oil line.

Looking forward to the rest of your build.

Hope you have access to good coffee up there in Windsor.

Last edited:

If you have access to a welder and have an extra steel clutch plate, you can make a better holding tool than the one Mike's sells .....

I bought one new steel plate (cheaper than the tool), put it in my clutch, and made the tool from the old plate. It works better because it holds the hub through 2 slots, not just 1.

I bought one new steel plate (cheaper than the tool), put it in my clutch, and made the tool from the old plate. It works better because it holds the hub through 2 slots, not just 1.

GeorgeOC

XS650 Junkie

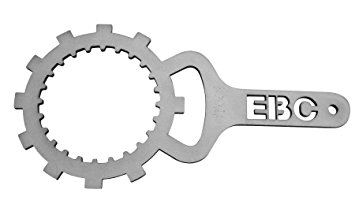

Great read Pete, thank you. FWIW, EBC sells a remarkable clutch tool. https://ebcbrakes.com/product/ebc-clutch-installation-and-removal-tools/

I believe it's the CT017 model. This made my work easy when reassembling the motor recently...

https://www.amazon.com/EBC-CT017-Clutch-Removal-Tool/dp/B0041C8YMY

I believe it's the CT017 model. This made my work easy when reassembling the motor recently...

https://www.amazon.com/EBC-CT017-Clutch-Removal-Tool/dp/B0041C8YMY

Ah, I shouldn't have gone to bed so early , I missed the second half! Nice write up Pete.

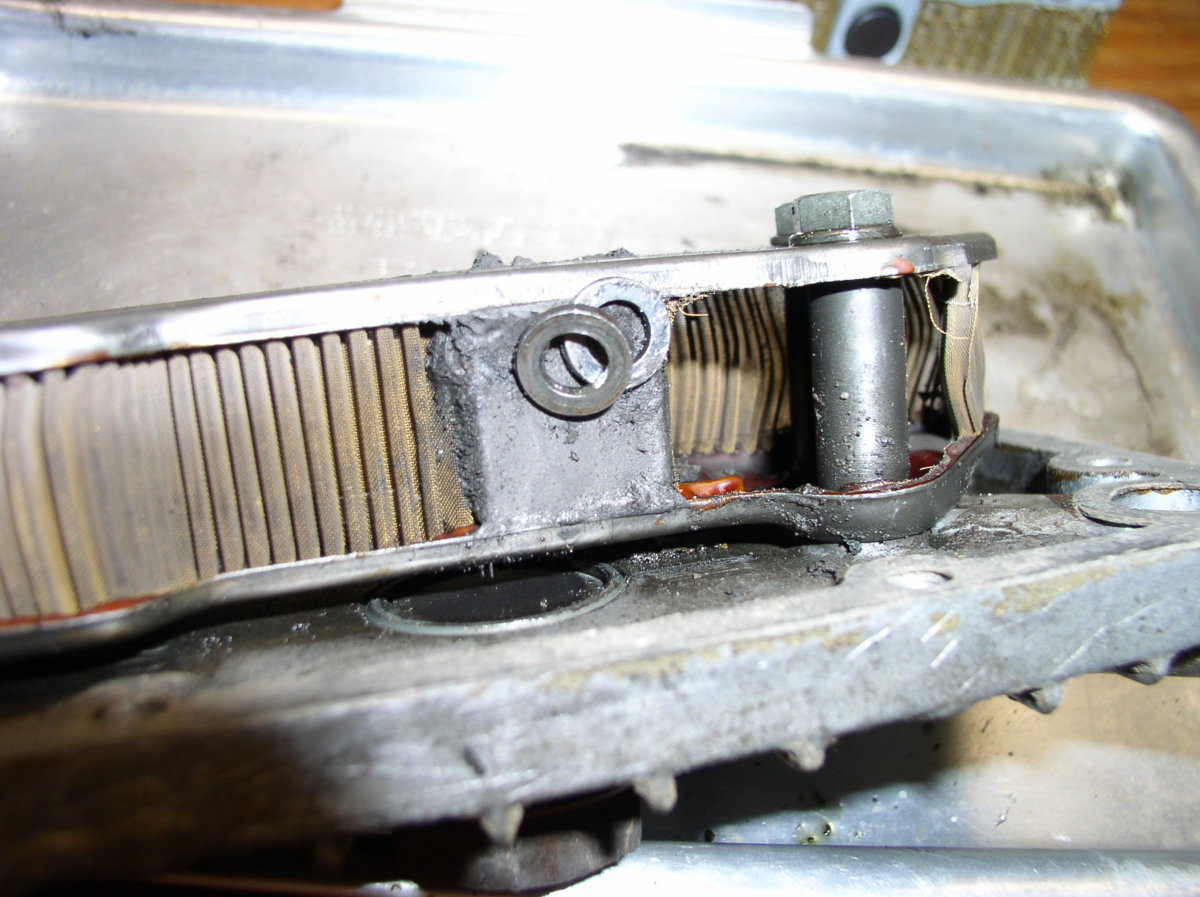

Was this the gear that came off of your bike?

If so, you can really see how worn that gear was. Also you were satisfied with the quality of the spring that came with the replacement gear from Mikes correct? And you kept the NOS spring just for a spare. The idea of tipping the bike makes good sense also.

Well done.

Was this the gear that came off of your bike?

If so, you can really see how worn that gear was. Also you were satisfied with the quality of the spring that came with the replacement gear from Mikes correct? And you kept the NOS spring just for a spare. The idea of tipping the bike makes good sense also.

Well done.

GeorgeOC , that EBC clutch tool looks pretty nice too, for those of us without access to a welder to make our own.

Hi All:

George - thanks for the info she n the EBC tool - it does look good!

Mailman:

Yup, the XSDirect / MikesXS replacement unit was OK in all respects - EXCEPT - the supplied hairpin was too loose with a slip force of only about 4.5 lb. I didn't realize this initially because I didn't test it. As a result, I barged ahead and installed it as-supplied and the starter sounded like a coffee grinder. Once I did test it with my fish scale and found the low slip force, I simply mounted the assembled XSDirect / MikesXS unit in my vise and did the squeeze. The new slip force was well over 12 lb, so all was well - and that is the unit I have installed.

The coil backup spring that sits BEHIND gear 4 was much stiffer on the XSDirect / MikesXS unit than on the "old" one that I took off the bike - so I used it as well.

Finally, the rubber surface on the backside of the "old" gear #4 was a little chewed-up much like the one in your photo above - and that is why I didn't re-install it, but have kept it as a spare. It is now sitting in my parts box with one of my two NOS OEM hairpins on it and the other NOS hairpin is sitting right beside it.

I have had a couple of PM questions about all of this swapping of parts and so I will clarify as follows:

Everything that is on the bike now came from XSDirect / MikesXS - the only modification being that I did the squeeze on the hairpin. Incidentally, that operation is done with a vise and the hairpin mounted on the gear. You just need to be careful to NOT get the actual gear teeth tangled up with the jaws of the vise.

Squeeze ONLY the wire hairpin and NOT any part of the gear itself.

Thanks again for all the help everyone!

Pete

George - thanks for the info she n the EBC tool - it does look good!

Mailman:

Yup, the XSDirect / MikesXS replacement unit was OK in all respects - EXCEPT - the supplied hairpin was too loose with a slip force of only about 4.5 lb. I didn't realize this initially because I didn't test it. As a result, I barged ahead and installed it as-supplied and the starter sounded like a coffee grinder. Once I did test it with my fish scale and found the low slip force, I simply mounted the assembled XSDirect / MikesXS unit in my vise and did the squeeze. The new slip force was well over 12 lb, so all was well - and that is the unit I have installed.

The coil backup spring that sits BEHIND gear 4 was much stiffer on the XSDirect / MikesXS unit than on the "old" one that I took off the bike - so I used it as well.

Finally, the rubber surface on the backside of the "old" gear #4 was a little chewed-up much like the one in your photo above - and that is why I didn't re-install it, but have kept it as a spare. It is now sitting in my parts box with one of my two NOS OEM hairpins on it and the other NOS hairpin is sitting right beside it.

I have had a couple of PM questions about all of this swapping of parts and so I will clarify as follows:

Everything that is on the bike now came from XSDirect / MikesXS - the only modification being that I did the squeeze on the hairpin. Incidentally, that operation is done with a vise and the hairpin mounted on the gear. You just need to be careful to NOT get the actual gear teeth tangled up with the jaws of the vise.

Squeeze ONLY the wire hairpin and NOT any part of the gear itself.

Thanks again for all the help everyone!

Pete

Last edited:

I have just made reference to the older Tech threads on the starter gear repair, but it appears that they have succumbed to the "Photobucket debacle". I have read the discussion from earlier this month in the thread regarding this picture-hosting issue, but am wondering what the future holds for the XS650.com Tech section, in general, assuming that Photobucket was used for a lot of those thread pics. Will the Tech section need to be "rebuilt"?

As for myself, I don't use any aspect of the cloud. Never trusted the concept.

As for myself, I don't use any aspect of the cloud. Never trusted the concept.

I think that chewed up rubber "pad" on the #4 starter gear is responsible for many of the little rubber chunks you find in your oil filters, not the front cam chain guide. The guide usually falls apart in long strips or just falls off the aluminum base whole, lol.

I think that chewed up rubber "pad" on the #4 starter gear is responsible for many of the little rubber chunks you find in your oil filters, not the front cam chain guide. The guide usually falls apart in long strips or just falls off the aluminum base whole, lol.

You know 5T, I'll bet that you are precisely correct on that.

I did find a lot of little bits of crap lying in several of the nooks and crannies of the RH engine case cover and I spent quite a bit of time cleaning it up. To me, that suggests that the oil circulation within the XS650 engine may be a bit weak - but as long as those bits and pieces don't cause trouble by getting into bearings etc, I guess it's nothing to worry too much about.

Last edited:

It ain't killed most of these engines yet, lol. Usually, the filters are terribly gunked up and full of crap on a new-to-you 650 because they were never cleaned often enough. It took several thousand miles and multiple oil changes and filter cleanings before my filters started coming out clean. It takes quite some time to flush that long time build-up out.

That's why I'm a big fan of having an extra side filter and sump plate/filter assembly, clean and ready to swap in at oil changes.

That's why I'm a big fan of having an extra side filter and sump plate/filter assembly, clean and ready to swap in at oil changes.

I just removed this sump from my new-to-me '80 :

Holy cow 'Dude - how the heck did those two washers get there? Was any part of Jimmy Hoffa in there as well?

OK - on to another topic:

After I finished the starter hairpin and clutch reassembly late last night, I started the bike (yeah baby - worked like a charm). I was using the newly rebuilt BS34s with NO air box or pod filters and the stock '81 Special fuel tank with the vacuum peacock set on PRIME.

After a few seconds, there was fuel dribbling out of the danged carbs (a bit scary actually ).

).

I guess a float needle may be stuck....but I have no experience with these petcocks. Any other suggestions about where to look for problems before I pull off the carbs <again>?

I also have a question and a request:

Pete

OK - on to another topic:

After I finished the starter hairpin and clutch reassembly late last night, I started the bike (yeah baby - worked like a charm). I was using the newly rebuilt BS34s with NO air box or pod filters and the stock '81 Special fuel tank with the vacuum peacock set on PRIME.

After a few seconds, there was fuel dribbling out of the danged carbs (a bit scary actually

).

).I guess a float needle may be stuck....but I have no experience with these petcocks. Any other suggestions about where to look for problems before I pull off the carbs <again>?

I also have a question and a request:

- To what does the vacuum barb on the petcock connect? It isn't obvious to me where the vacuum source actually is.

- Could someone please post a photo of an '81 Special showing how the airboxes are installed - including the PCV hose routing? I have the parts, but this is crowded part of the bike and the routing is not obvious to me.

Pete

Last edited:

To what does the vacuum barb on the petcock connect?

Your intake manifold should have a barb on it.

Your intake manifold should have a barb on it.

Do you mean one of the two spigots that are capped off - the ones used for carb balancing manometers?

BOTH carbs are leaking?Holy cow 'Dude - how the heck did those two washers get there? Was any part of Jimmy Hoffa in there as well?

OK - on to another topic:

After I finished the starter hairpin and clutch reassembly late last night, I started the bike (yeah baby - worked like a charm). I was using the newly rebuilt BS34s with NO air box or pod filters and the stock '81 Special fuel tank with the vacuum peacock set on PRIME.

After a few seconds, there was fuel dribbling out of the danged carbs (a bit scary actually).

I guess a float needle may be stuck....but I have no experience with these petcocks. Any other suggestions about where to look for problems before I pull off the carbs <again>?

I also have a question and a request:

Many thanks for any and all info!

- To what does the vacuum barb on the petcock connect? It isn't obvious to me where the vacuum source actually is.

- Could someon please post a photo of an '81 Special showing how the airboxes are installed - including the PCV hose routing? I have the parts, but this is crowded part of the bike and the routing is not obvious to me.

Pete

Yup.Do you mean one of the two spigots that are capped off - the ones used for carb balancing manometers?

Well, good question - I only saw the LH one leaking but I'll have to check that. At that moment in time, I was mainly focussed on preventing "an earth shattering kaboom"

I am still puzzled about this vacuum line thingy? Both of my carb vac outlets are plugged with what look like factory caps.

Any chance you could post a photo and also one of the airbox installation?

I am still puzzled about this vacuum line thingy? Both of my carb vac outlets are plugged with what look like factory caps.

Any chance you could post a photo and also one of the airbox installation?

Last edited:

Your petcock might be letting gas through (like it has failed). The float needles are not actually designed to FULLY shut off the gas, am I correct?Holy cow 'Dude - how the heck did those two washers get there? Was any part of Jimmy Hoffa in there as well?

OK - on to another topic:

After I finished the starter hairpin and clutch reassembly late last night, I started the bike (yeah baby - worked like a charm). I was using the newly rebuilt BS34s with NO air box or pod filters and the stock '81 Special fuel tank with the vacuum peacock set on PRIME.

After a few seconds, there was fuel dribbling out of the danged carbs (a bit scary actually).

I guess a float needle may be stuck....but I have no experience with these petcocks. Any other suggestions about where to look for problems before I pull off the carbs <again>?

I also have a question and a request:

Many thanks for any and all info!

- To what does the vacuum barb on the petcock connect? It isn't obvious to me where the vacuum source actually is.

- Could someon please post a photo of an '81 Special showing how the airboxes are installed - including the PCV hose routing? I have the parts, but this is crowded part of the bike and the routing is not obvious to me.

Pete