here,s my wheel polisher ,old ride-on-mower spindle and belt

'View attachment 151887 View attachment 151888

What caught my eye was the Z1 in the background

here,s my wheel polisher ,old ride-on-mower spindle and belt

'View attachment 151887 View attachment 151888

View attachment 164192 As suggested I’ll add this here.

Sprocket holding tool.

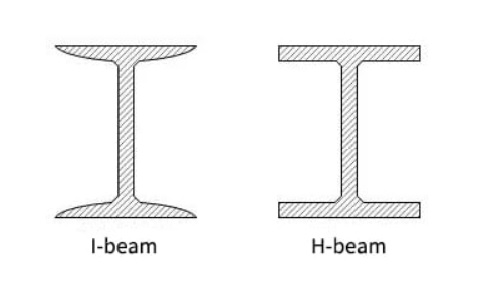

Well, I was at it again this past summer with my little welder, lol. I had this 4'- 6" long length of scrap I-beam, actually it's an H-beam. An H-beam differs from an I-beam in that the top and bottom flanges are parallel to one another and not tapered .....

This makes it ideal for clamping stuff to it. Even though it was just laying loose atop my scrap metal pile, I often did just that, clamping pieces of metal to it for drilling, cutting, and/or grinding. It was very handy for this but obviously not that stable just sitting there loose on top of the scrap pile, lol. So, I decided to turn it into a couple of small, heavy duty (very heavy duty as it turned out) saw horses. First step was to cut the beam in half, giving me two shorter ones about 27" long .....

With the leg assemblies installed, the horses sit about 17.5" high .....

The leg assemblies just slide on the ends of the beams and are held in place by set bolts .....

The set bolts were turned into "T'' bolts by welding a strip of plate across the tops, so they can be loosened and tightened by hand .....

I wanted the legs to come off so I could easily break them down for transport. They turned out great and I've been using the heck out of them, lol.

Well, I was at it again this past summer with my little welder, lol. I had this 4'- 6" long length of scrap I-beam, actually it's an H-beam. An H-beam differs from an I-beam in that the top and bottom flanges are parallel to one another and not tapered .....

This makes it ideal for clamping stuff to it. Even though it was just laying loose atop my scrap metal pile, I often did just that, clamping pieces of metal to it for drilling, cutting, and/or grinding. It was very handy for this but obviously not that stable just sitting there loose on top of the scrap pile, lol. So, I decided to turn it into a couple of small, heavy duty (very heavy duty as it turned out) saw horses. First step was to cut the beam in half, giving me two shorter ones about 27" long .....

With the leg assemblies installed, the horses sit about 17.5" high .....

The leg assemblies just slide on the ends of the beams and are held in place by set bolts .....

The set bolts were turned into "T'' bolts by welding a strip of plate across the tops, so they can be loosened and tightened by hand .....

I wanted the legs to come off so I could easily break them down for transport. They turned out great and I've been using the heck out of them, lol.

or the industrial version; pins sized to fit the head recess diameter.View attachment 182687

This is the tool I made for removing stuck oil screen covers.

View attachment 182688

Here it is in use.

View attachment 182689

The tool consists of a piece of hardwood salvaged from a chair rail. The studs are full-diameter M6 shanks cut from really long M6 bolts. The wood started splitting when I used it on a particularly stuck-on cover, so I added the three wood screws for reinforcement.

It's surprising how often these covers are stuck on bikes that weren't maintained. Or, when owners get heavy-handed with gasket cement, and it oozes all over. I now routinely use this tool on any cover that doesn't just fall out by itself.

.jpg)

Here's a couple pics showing the frame of the truing stand and it in use. Made mostly with 1" DOM, a piece of hex bored for bearings, 15mm linear bearing shaft, aluminum for the cones and a piece of 1/4" steel to hold a mag base. Got the idea for single sided from the motionpro stand, but skipped out of the folding bit.

View attachment 183791 View attachment 183792

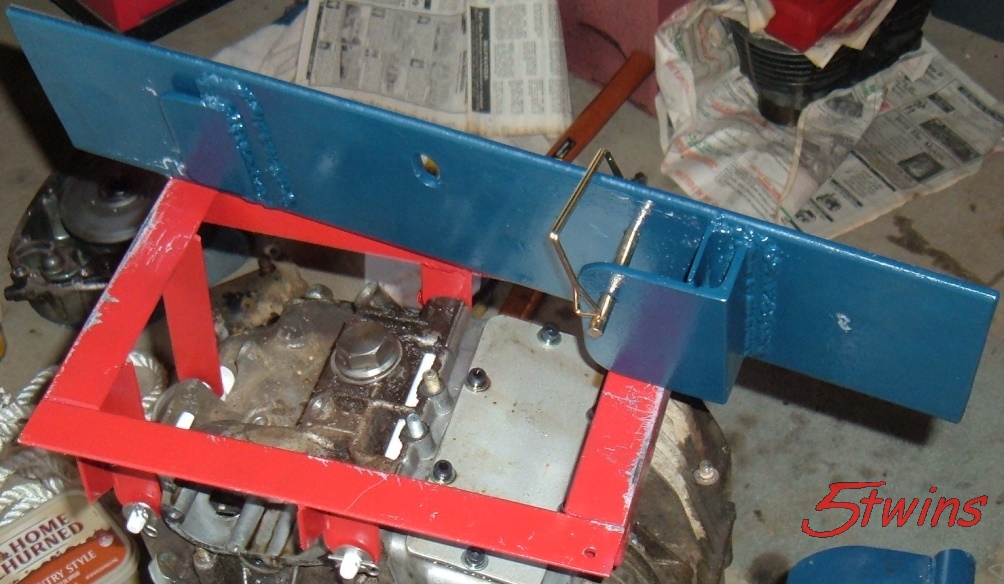

When I built my little "flip" stand several years back, I got the idea that I might be able to split the cases using the power of hydraulics by placing a bottle jack at the front. All I'd need is a plate of some sort to attach to the motor stand on top .....

Well, I finally got around to making the plate .....

It has brackets on it so it locks onto the engine stand at the front and rear .....

Since the bottle jack will only lift and separate the front of the cases, I made the plate long enough so I could use a big rubber mallet at the rear to separate the back end .....

So, here it is all set up and ready to go .....

A couple of pumps on the bottle jack and ..... pop!! Success!! .....

Then a few good whacks with the rubber mallet upward on the overhanging plate at the rear, and it's a done deal .....

Wow, this was too easy, lol.