Rexxis

Almost there...

Thanks Cleon!

Thanks George for encouraging me to update.

Sentricity, you were correct, check it out. Not only did my electronics box interfere but the frame did as well.

So I chopped them bitches up!

Before and after.

Had to notch the elec box to allow the filters to clear.

Finished up my seat, idk why the pic is a screenshot of my phone, I don't remember it being like that, whatever. And yes I have 700+ pictures on my phone and its slowing it down. I should do something abt that..

Got down to business on the sissy bar.

I found a quality, all metal brake switch at a local bike salvage call A&A cycle, more abt them shortly..

I like the way the switch wires look from the outside.

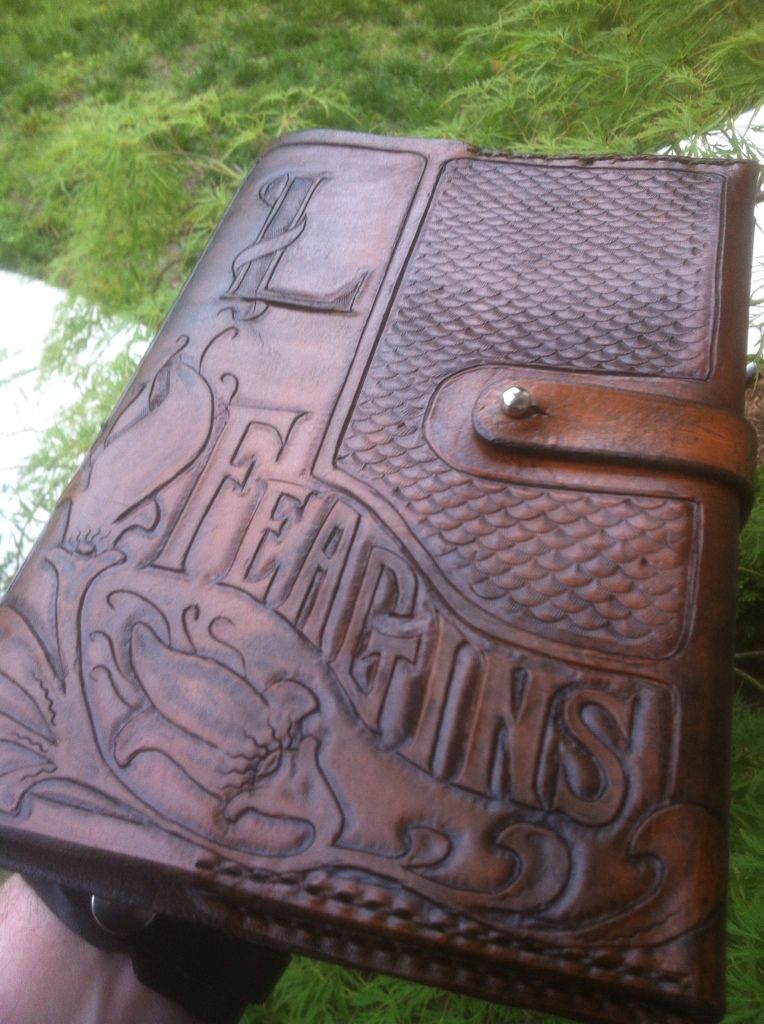

Well, I'm gonna be covering my seat soon so I figured I should start brushing up on my leather working skills. I made mom a planner cover thingie for moms day.

So I found the motherload of motorcycle salvage here in OKC. It's called A&A Cycle Salvage. This is just a fraction of all that is there.

Tanks galore, this shot x 10. I couldn't get a good picture of them bc they are hanging everywhere

4 or so aisles like this. If you look close, theres a girder sitting back there, I just now noticed it. Haha

One more shot of the bike.

Thanks George for encouraging me to update.

Sentricity, you were correct, check it out. Not only did my electronics box interfere but the frame did as well.

So I chopped them bitches up!

Before and after.

Had to notch the elec box to allow the filters to clear.

Finished up my seat, idk why the pic is a screenshot of my phone, I don't remember it being like that, whatever. And yes I have 700+ pictures on my phone and its slowing it down. I should do something abt that..

Got down to business on the sissy bar.

I found a quality, all metal brake switch at a local bike salvage call A&A cycle, more abt them shortly..

I like the way the switch wires look from the outside.

Well, I'm gonna be covering my seat soon so I figured I should start brushing up on my leather working skills. I made mom a planner cover thingie for moms day.

So I found the motherload of motorcycle salvage here in OKC. It's called A&A Cycle Salvage. This is just a fraction of all that is there.

Tanks galore, this shot x 10. I couldn't get a good picture of them bc they are hanging everywhere

4 or so aisles like this. If you look close, theres a girder sitting back there, I just now noticed it. Haha

One more shot of the bike.