Alright, I'm having some issues with my master cylinder rebuild - fighting and losing.

I got the kit suggested above (08-0219) and I can't for the life of me get the snap ring in. I have snap ring pliers, but not master cylinder snap ring pliers. Before either buying some or filing down some cheap hobby pliers, I took some measurements and think something is amiss.

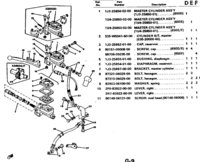

The bore for the cylinder is 14mm+/-, and the piston (plunger?) is basically 14mm. The snap ring and metal washer that came in my kit are 18.5mm. I was under the impression that the washer went between the piston and the snap ring, but given the size the only possible way I could reassemble this would be spring-->cap->plunger->snap ring->metal washer->rubber top hat boot. Given the washer's size, there's no way I could possibly get it into the bore to sit underneath the snap ring (Further down the chamber). My pliers were *just* too short to remove the snap ring, but I was expecting to be able to get the new ring in the bore and then use a pick or something to push it down into its home where it could expand.

Could my snap ring and washer be too large? I don't think I could get that snap ring seated even with the right pliers, it just seems to big. Then there's the washer - shouldn't that be 14mm as well to sit in the bore and press up on the snap ring?

For what its worth, when I took everything out the first time the order was spring->cap->brass disc->plunger->snap ring->rubber top hat boot. There was no washer at all. Am I dealing with an earlier model m/c or something? The snap ring that was originally inside broke when I took it out so I foolishly tossed it - wish I still had it to measure. Any ideas? I think the next step are some of those cheap harbor freight hobby pliers, but I'm still nervous that the snap ring isn't going to fit; and then there's the issue of what to do with the washer - just let it sit between the snap ring and the groove where the top hat boot seats?

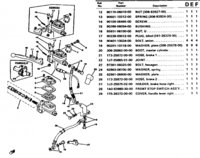

*Edit* as I mentioned before, my M/C has "ASCO 12" stamped on the bottom of the body and a 14 stamped on the top. I thought it a little odd that a reservoir o-ring I bought off Ebay was too thick, but figured the seller had the wrong part. In searching for ASCO12 master cylinder I'm getting results for RD400s and small Suziki GTs - kits available that look exactly what came out of my M/C (

http://www.discountbikespares.co.uk...IT-ASCOAISHIN-GT550500380-GT250185125-GS.html) & (

http://yambits.co.uk/fs1dx-brake-master-cylinder-repair-kit-front-p-33098.html). I'm officially confused - but I'm starting to think I have an RD400 Master Cylinder. When I search RD400 M/C I get a lot of my m/c - doesn't seem to cross reference the xs650.