Remember reading about that darn green base gasket? that’s mostly why the top end was disassembled, And to check over what this engine is about.

Incidentally, the front chain guide and mounts seem to be new MikesXS items not surprising at all. Those front chrome mounts are and have been noticed in other threads (Bob) to be slightly longer that original. I looked at this… discovered that the appropriate copper gaskets were in fact the same dimensionally as a neutral indicator switch gasket, except the neutral switch gasket is thicker. So I doubled up a neutral gasket with a chain guide gasket and wala, called it good.

Improvising is necessary on Your project!

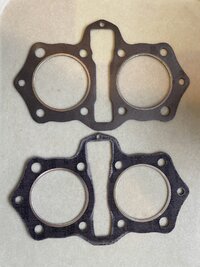

Now I’m looking at both of my in hand head gaskets. I seem to have an Athena and a SCM which are visibly different in thickness. Of course my battery is dead in my digital caliper, Dead battery! It’s normal for the times.

Im so tempted to get copper spray sealer like Jim suggests and use the thinner head gasket in hand.

And L

I was told this top end is “low mileage” and see nothing to doubt that statemen.

Anyway, that’s where it is currently. Pics~