No, Gary, I'm wide awake and fully caffeinated, and know whereof I speak. Every time I've dealt with XS650 carbs popping out of the boots it's been a case of worn bob weights with advance timing correctly set and idle timing way too far retarded. That experience includes diagnosis and correction of advance governor grief on the machines of two successive 650 Society directors (ask our mutual friend John about that). I don't like the look of those weights as much as you do. Good idea re. shims--faster than my old fix of pounding the bob weight tips to widen them. Might want to fashion the shim as a sleeve to give the glue more contact and a little mechanical support.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tuning.....Where the hek to start!

- Thread starter Paul75

- Start date

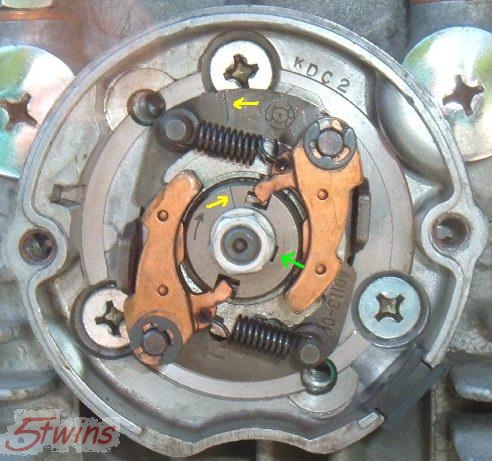

I have to agree with Gary, I don't think that advance unit looks worn much at all. Mine is worse and the bike still times up fine. If you look at the alignment slash marks on the little disc and advance backing plate, they still align very well. As you can see on mine, the little disc's mark is falling behind (yellow arrows) .....

Sometimes there is some play in the locating slot on the back of the advance unit. You might try loosening the retainer ring and rotating the unit one way or the other. That will alter the relationship between the advance unit and timing plate. The timing will fire at a slightly different spot. That might be enough to correct the idle timing.

Sometimes there is some play in the locating slot on the back of the advance unit. You might try loosening the retainer ring and rotating the unit one way or the other. That will alter the relationship between the advance unit and timing plate. The timing will fire at a slightly different spot. That might be enough to correct the idle timing.

You often have to adjust the gap a bit to compensate for cam chain stretch and get left right balanced. Careful that any advance degree knob on the timing light is zero'd out, been caught on THAT oopsie.

PS the advance setting is MUCH more important than the idle setting. Eventually most say F-it and put in a pamco, now with the integrated advancer on the plate it's nearly a no brainer.

Inability to bring the timing in is natures way of telling you it's time for a cam chain and guide....

"You often have to adjust the gap a bit to compensate for cam chain stretch and get left right balanced"

Sorry Gary, which gap are you refering to?

Points gap, it isn't critical, anywhere from say .010 to .016 is fine if that helps get the timing where it needs to be and balanced L-R

Playing with the gap is just altering the position on the cam where the points open/close. You can move this position higher up or lower down by altering the gap which then changes the ignition timing relative to TDC.

Edit: You can check this out with a bulb and marking the cam position for a small gap verses a large gap to see which retards or advances..

Edit: You can check this out with a bulb and marking the cam position for a small gap verses a large gap to see which retards or advances..

Last edited:

I changed my last entry because my thoughts are getting screwed up - Bad cold! I suggest checking which advances/retards by marking the cam before starting the engine.

To understand what effect the size of the points gap will have on the timing, you need to understand how the points operate. The high spot on the points cam pushes on the rubbing block which opens the points. To open them more, you need to move the points set closer to the cam so the high spot pushes the points open more. This also means that as the cam spins around, it's high spot will contact the rubbing block a little sooner. This will advance your timing a little. So yes, a larger gap will advance the timing.

To experiment with the advance mounting, you need to loosen that big notched ring that holds the unit on the cam. No, this won't change the alignment of the two slash marks. The amount of wear on the ends of the weights where they fit into the slots on the little center disc determine that.

To experiment with the advance mounting, you need to loosen that big notched ring that holds the unit on the cam. No, this won't change the alignment of the two slash marks. The amount of wear on the ends of the weights where they fit into the slots on the little center disc determine that.

... with idle timing too far retarded, you'll experience hard starting and carbs popping out of the boots...

Have another cup of coffee this deary sunday morning Grizzly bear, advanced idle timing will pop the carbs off not so much retarded....

No, Gary, I'm wide awake and fully caffeinated, and know whereof I speak. Every time I've dealt with XS650 carbs popping out of the boots it's been a case of worn bob weights with advance timing correctly set and idle timing way too far retarded...

Ooooooh, this is a good'n. Let's get into it.

Numerous posts about this carb backfire, *chuff*, *pop* issue, and I've experienced it myself.

Been thinking on this for years. An interesting conundrum.

Consider that the XS650 points ignition has about 90° dwell, which translates to roughly 180° at the crank. If the idle timing is about 15° BTDC, which is when the points open, then the points are closing 180° before that, about 15° BBDC. if the timing is too retarded, say about 5° BTDC, then the points closure would be about 5° BBDC.

Note that the intake valve is still open when the points close.

Now, consider at what point in the start attempt when this backfire, *chuff*, *pop* occurs.

I've only experienced this a few times on my XS1b, but it has ALWAYS occurred at the END of a kickstart attempt. NEVER during the kickstart cycle, only AFTER the engine has spun, then come to rest.

I'm thinking that, as the engine spins down, with its last bit of angular momentum (rotational energy):

- Pistons approach BDC, one intake valve is closing,

- Points close, coil energizes,

- Pistons continue traveling past BDC,

- An intake valve closes, that cylinder enters compression stroke,

- Piston travels upward, beginning compression,

- *grunt*, not enuff energy to compete compression cycle,

- There's some compression pressure in there, fighting the piston's last gasp,

- Engine rotation stops,

- Residual compression pressure forces piston back down,

- Engine now rotating backwards,

- Intake valve reopens,

- Piston passes BDC in reverse,

- The currently closed points now open,

- *spark*,

- *blammo*

If the ignition timing is correct, the crank/piston will have to travel backwards at least 15° past BDC for the points to open. There may not be enuff rotational energy for the engine to spring back this far. If the timing is retarded, that would be an advanced condition for a backwards turning engine. If the retarded timing was at 5° BTDC, the backwards points opening would be closer to BDC, only 5° away, and that reversing engine may actually reach that position. Points open. Backfire thru opened intake valve.

This supports Grizld1's position,

And my experiences, since I prefer an overly retarded idle timing.

Is this viable? Does it make *any* sense at all?

I suppose the only way to know for sure is to closely monitor the points cam, see if any rearward motion, and if its enuff to re-open a point...

I stand corrected? Haven't blown the carbs off the 79 standard yet, currently my only regular ride with points. IIRC I set points and timing to spec fairly early on. I also run stock air boxes bolted in place..... I have blown off a few sets of carbs over the years mostly while road testing. I think the resto did it a time or two before I pamco'd it. Several in here have reported carbs blown off at a stop light. Worn points parts, random opening events?

Sounds reasonable, 2M. I don't know the why and the wherefore. All I know is what happens, a few things to do about it, and one thing you shouldn't even think about doing, all of it learned the hard way. Gary, I haven't seen carbs blown out of boots at stop lights or gotten my hands on a motor that did that, so I can't speak to that issue. More than one defect could be at work to cause that. Every time I've dealt with the problem hands-on it's occurred as 2M describes, after the kick or starter button release. So far that hands-on experience with escaping carbs and advance governor correction has been with six XS650s: two of my own and four belonging to others.

Last edited:

"To experiment with the advance mounting, you need to loosen that big notched ring that holds the unit on the cam."To understand what effect the size of the points gap will have on the timing, you need to understand how the points operate. The high spot on the points cam pushes on the rubbing block which opens the points. To open them more, you need to move the points set closer to the cam so the high spot pushes the points open more. This also means that as the cam spins around, it's high spot will contact the rubbing block a little sooner. This will advance your timing a little. So yes, a larger gap will advance the timing.

To experiment with the advance mounting, you need to loosen that big notched ring that holds the unit on the cam. No, this won't change the alignment of the two slash marks. The amount of wear on the ends of the weights where they fit into the slots on the little center disc determine that.

5T, is there a set procedure when experimenting with the advance mounting?

I'm not trying to be mean or snarky, Paul, but you'll have an easier time if you start to think about how these things work. Ask yourself this question: If you rotate the points cam in the direction of engine rotation, will the points open sooner or later? If you rotate the points against the direction of engine rotation, will it retard or advance the points opening? (Given: when the whole governor assembly rotates on the camshaft, the points cam rotates with it.)

Not really, turn it full hard in one direction to take up the play, tighten the ring retainer, check the timing to see if it helped. If not, or if it made it worse, loosen it again and turn it in the other direction. Turning it one way will retard the timing, the other will advance it, but I can't tell you off hand turning which way will do what.

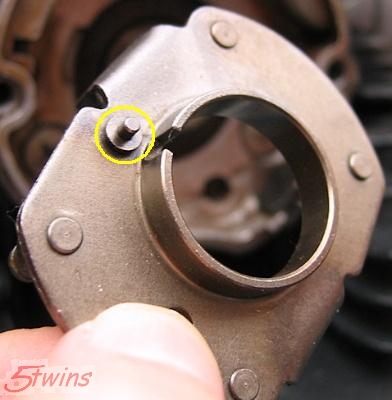

The advance unit has a slot on the back that fits on a little locating pin stuck into the side of the cam. You can see the slot here just to the right of the yellow circle. The circled peg is a stop to hold the pin in the cam so centrifugal force doesn't eject it as the cam spins .....

The advance unit is normally a pretty good snug fit on the pin but if it was run for a while with the retaining ring loose, the unit could rock or work back and forth, causing wear to the slot. That could then effect the timing if the advance unit was not installed and locked on the cam in it's original position.

The advance unit has a slot on the back that fits on a little locating pin stuck into the side of the cam. You can see the slot here just to the right of the yellow circle. The circled peg is a stop to hold the pin in the cam so centrifugal force doesn't eject it as the cam spins .....

The advance unit is normally a pretty good snug fit on the pin but if it was run for a while with the retaining ring loose, the unit could rock or work back and forth, causing wear to the slot. That could then effect the timing if the advance unit was not installed and locked on the cam in it's original position.

It's usually a good idea to pull the advance unit right off and inspect all this stuff when you first get one of these bikes. Make sure the locating pin is present in the side of the cam (sometimes they're missing) and inspect the slot on the back of the advance unit for wear. Sometimes they're pretty hammered. The advance unit usually needs a good cleaning anyway. It's just raw steel so can get all rusty. I coat mine lightly with motor oil to prevent that. Not much, just enough to make it shine. Too much and it will just fling off as it operates and make a mess inside the housing.

"To experiment with the advance mounting, you need to loosen that big notched ring that holds the unit on the cam."

5T, is there a set procedure when experimenting with the advance mounting?

In addition to the above advice, I'd also suggest making changes in fairly small increments - and only change one thing at a time. That way, you can really assess the effects your work is having on how the engine runs.

I know that may seem obvious, but in my experience anyone can fall into the trap of "going at it", particularly if a whole bunch of interesting new parts and/or tools or other toys has just arrived.

....don't ask me how I know this....

Cheers,

Pete

No you are absolutely right, just spent the last hour or so going back over the points, re-setting, turning, turning and generally figuring things out so as to understand it better.....there is no substitute for garage time! I have been back to the start of this thread a couple times too to re-read, it's amazing how much more info can be digested a second time over.......I'm not trying to be mean or snarky, Paul, but you'll have an easier time if you start to think about how these things work. Ask yourself this question: If you rotate the points cam in the direction of engine rotation, will the points open sooner or later? If you rotate the points against the direction of engine rotation, will it retard or advance the points opening? (Given: when the whole governor assembly rotates on the camshaft, the points cam rotates with it.)

Indeed.

I have found on things like the points-setting and timing procedure, If you simply read the procedure, it sounds like constitutional law - but if you actually stare at the parts while reading it, the entire process becomes clear and actually quite intuitive.

Tell me - and I might learn, show me and I will understand.

I have found on things like the points-setting and timing procedure, If you simply read the procedure, it sounds like constitutional law - but if you actually stare at the parts while reading it, the entire process becomes clear and actually quite intuitive.

Tell me - and I might learn, show me and I will understand.

Last edited:

..... and it does get easier with practice, even though it remains a P.I.T.A., lol. I can remember the 1st set of points I ever replaced many years ago. I couldn't get a peep out of the new ones and had to put the old ones back in. Turns out I made one of the most basic mistakes - I didn't clean the oil off my feeler gauge blade before sticking it in the points. I fouled the faces and they wouldn't fire at all.