Thank you. Toglhot. I like the 535 GT too. It's bizarre how some of us end up with the bikes we do end up with. Mrs thinks I should buy a Classic 350 - for under £4,500 I would have a brand new reliable economical bike in a very similar style to the Bullet. Instead, I perversely buy a bike first brought to the market in approximately this form in 1948 and then spend my time dealing with the, uhm, issues. As you have read, have pretty much fully rewired the bike so I feel it will be more reliable and more susceptible to me being able to find faults that arise. No immediate plans to ditch the Boyer but thanks for the suggestions.

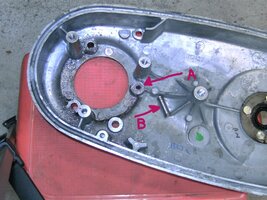

Yesterday, started out on replacing the inner chaincase and had a surprisingly successful day considering I haven't splurged out on the necessary special tools.

View attachment 215361

Remove brake lever, footpeg, outer chaincase. Then the alternator stator and pull the cables out. Ah, but next you need to put bike in gear and apply rear brake to lock the engine. Hmm, small block of wood under the tyre sufficed. Able to undo the rotor nut and to my surprise & delight the rotor pulled off by hand, extractor not needed this time.

Dismantled the clutch springs and plates and similarly able to loosen the centre nut without a locking tool - the small block of wood jammed in the primary chain was enough.

Wiggling the crankshaft sprocket and clutch basket gave me hope that these might not put up too much of a fight. With no clutch puller, I used the clutch cap, which normally retains the springs. Put a screw inside the hollow gearbox shaft to protect the end, placed a piece of sawn off bolt that was in me box of hardware bits'n'pieces to take up the distance, wound the three clutch cap screws in and the clutch basket pulled out with no drama, along with crankshaft sprocket and primary chain.

View attachment 215362

So those bits in the tray are the special tools what got me this far. At which point, quit while I was ahead.

Today, see how the inner chaincase comes out. Then will have to face drilling holes in the crankcase. Hmmmm.