hoffman900

XS650 Addict

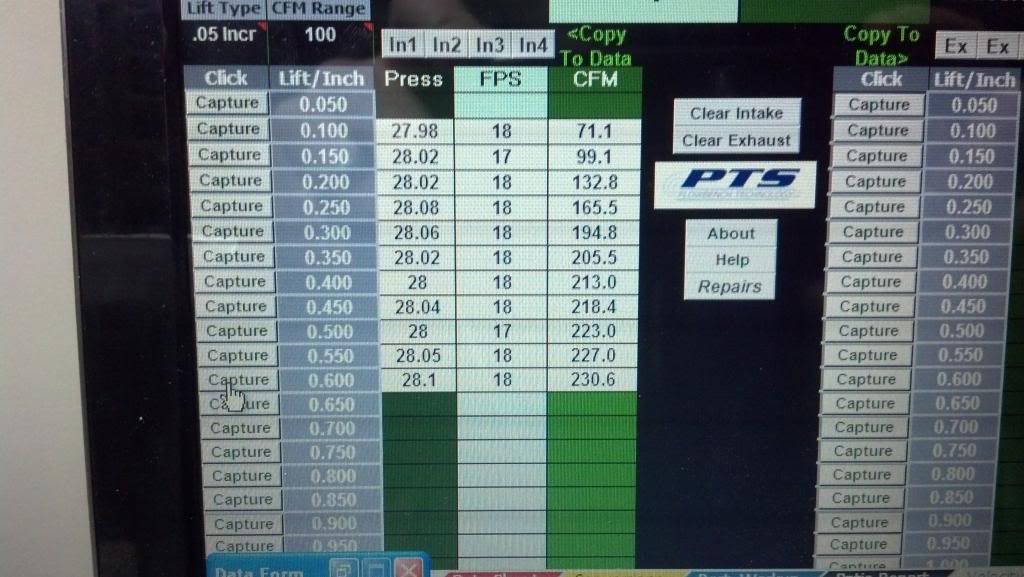

Playing around with things a little more. He has a special valve shape that works well in his Chrysler Hemi work (sorry, I'm holding the shape of that close to my chest). He had a blank come in for another project, so after he got done playing with that, he cut it down so it was ~2mm larger than standard and flowed it. Keep in mind the seat is still at sized for the 47mm valve. Pretty cool to see how it picked up low through the mid. You can see as valve lift increased, the throat/seat became the controlling factor in airflow, hence it didn't really change.

Of course, once the seat is cut, numbers will surely shift around.

The next step is to order valves after the retainer and locks for the 7mm valve stems come in, and open up the valve seat.

I also found someone who will machine a velocity stack with a elliptical profile and a full radius around the periphery.

Of course, once the seat is cut, numbers will surely shift around.

The next step is to order valves after the retainer and locks for the 7mm valve stems come in, and open up the valve seat.

I also found someone who will machine a velocity stack with a elliptical profile and a full radius around the periphery.