Norton7d

XS650 Junkie

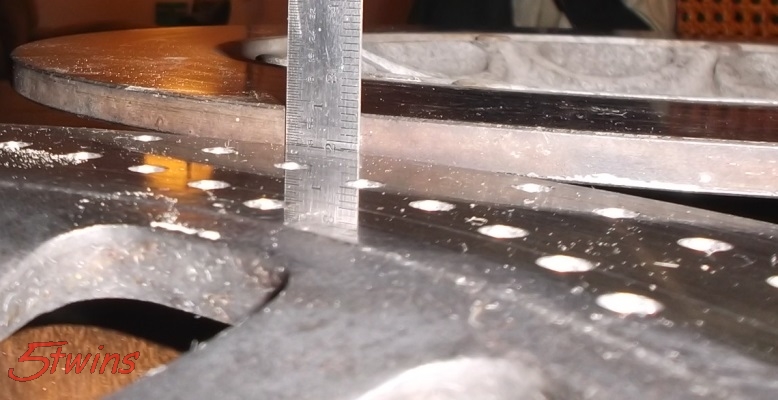

If I run the pad shims, I notice the wavy-ness of my rotor, no shims is better but then I can hear my outside pad moving forward and back in the caliper which makes a clicking noise, so much so the clicking is bothersome at any speed.

So its likely time for a new rotor but everything new and not fancy is for 77 and newer?

What about us old guys?

Thanks.

So its likely time for a new rotor but everything new and not fancy is for 77 and newer?

What about us old guys?

Thanks.