Royboy

many roads, little time

- Messages

- 1,079

- Reaction score

- 199

- Points

- 63

One of the guys on my staff, Justin, is a very strong guy. Yesterday he was cinching something down pretty tightly on my vintage Craftsman bench vise and he actually twisted off the threaded shaft that is the heart of any vise. It had served me well for a long time but I always knew that it was kinda weak mechanically.

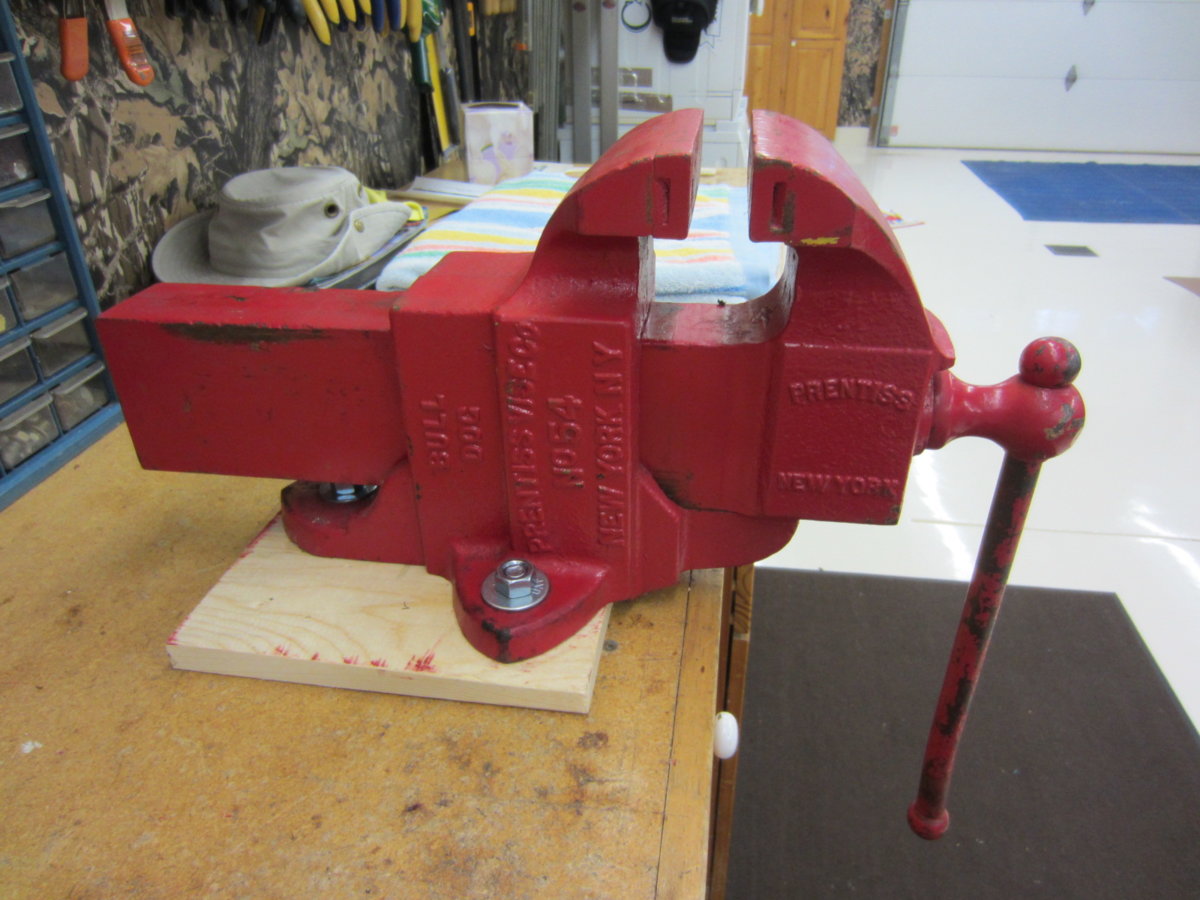

A few years ago a customer had given me his grandfathers old vise since he had no use for it. When the Craftsman crapped out I recalled that I had the old gift vise in storage so I dug it out and mounted it up on the bench. It's a Prentiss Bull Dog #54 about 100 years old I guess. This sucker weighs 74 lbs. Looks a little silly mounted as it is but will do for the moment.

If Justin twists this one off I want to be there to see it.

roy

A few years ago a customer had given me his grandfathers old vise since he had no use for it. When the Craftsman crapped out I recalled that I had the old gift vise in storage so I dug it out and mounted it up on the bench. It's a Prentiss Bull Dog #54 about 100 years old I guess. This sucker weighs 74 lbs. Looks a little silly mounted as it is but will do for the moment.

If Justin twists this one off I want to be there to see it.

roy

Last edited: