As I am now looking to further tune the exhaust on my project: https://www.xs650.com/threads/700cc-kit-with-a-shell-1-cam-in-a-78xs650e.65405/

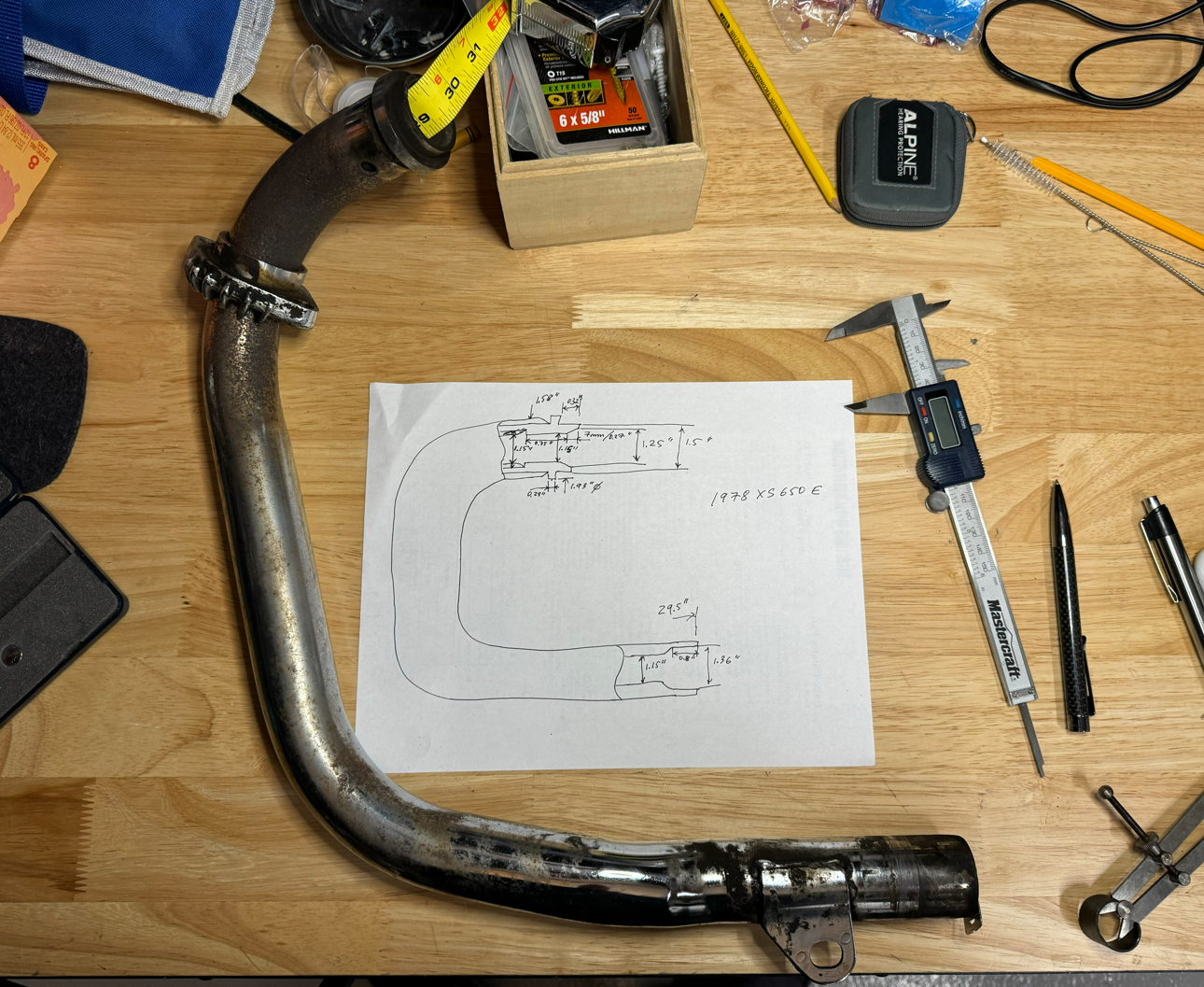

I took dimensions on the stock headers that may be of interest to some.

Overall the ID is 1.15” and the length is 29.5”. At the exhaust port there is an insert that almost looks like a “torque cone”, but I don’t think it does anything as the diameter of the pipe and the cone quickly reduce to 1.15”.

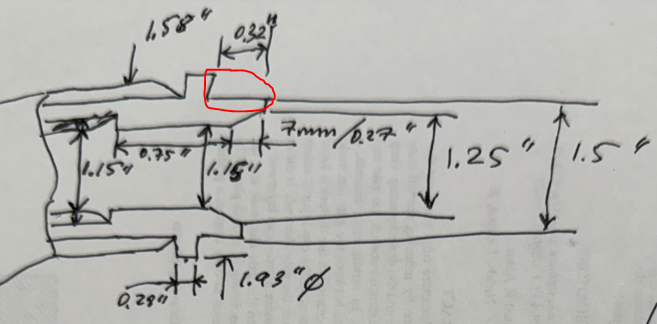

At the exhaust port of the head

at the muffler facing end

One thing I notices is that the “shoulder” beyond the gasket ring that fits into the exhaust port is only 8mm (0.32”)

which is not long enough to bridge to the depth of the cutout pocket inside the port itself and to ensure a smooth transition from the port to the headpipe:

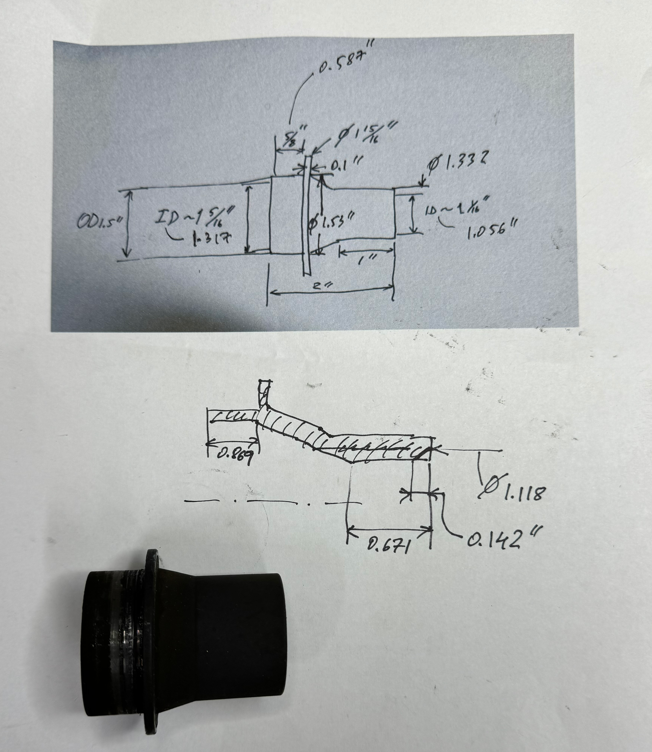

The depth of this pocket is 15mm and is taken well into account by the design of the exhaust optimizers from yamahaxs650.com

I will be soon testing 1.75" headers with these exhaust port inserts and MMM's torque peak optimizers on my 700cc build. The 1.75" headers without the mods did not do well for me.

I took dimensions on the stock headers that may be of interest to some.

Overall the ID is 1.15” and the length is 29.5”. At the exhaust port there is an insert that almost looks like a “torque cone”, but I don’t think it does anything as the diameter of the pipe and the cone quickly reduce to 1.15”.

At the exhaust port of the head

at the muffler facing end

One thing I notices is that the “shoulder” beyond the gasket ring that fits into the exhaust port is only 8mm (0.32”)

which is not long enough to bridge to the depth of the cutout pocket inside the port itself and to ensure a smooth transition from the port to the headpipe:

The depth of this pocket is 15mm and is taken well into account by the design of the exhaust optimizers from yamahaxs650.com

I will be soon testing 1.75" headers with these exhaust port inserts and MMM's torque peak optimizers on my 700cc build. The 1.75" headers without the mods did not do well for me.

Last edited: