I have also just waded through this entire thread and to be perfectly frank its just too wordy and full of extraneous stuff thats not needed.

I'm a persistant sob so I read all of it but most owners looking for a simple clear troubleshooting guide are not going to have either the time or inclination to wade through 7+ pages and be able to retain it all. All the questions and discussions about modified wiring systems and non standard components should be kept seperate in order not to confuse the issue

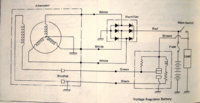

What is needed in my humble opinion is a simple troubleshoot flowchart and a seperate simple pictorial troubleshooting guide with a completely seperate thorough tutorial with a clear explanation of how the charging system works , the components , modifications, upgrades and model year differences as a locked sticky

Its too unwieldy to try incorporate the lot together in a single guide.

People need to see clearly how to test their charging system without necessarily having to wade through complicated explanations of how it all works.

Personally I like flowcharts but most folk will find it easiest to follow a video troubleshooting guide .Carbon Airwolfie Anlaf and others have done some excellent video tutorials and they have clearly been extremely helpful if the number of positive feedbacks and thanks are anything to go by.

I'd be happy to contribute to producing something but I only the components for have a 1979 model

I did do a quicky video a year ago but it was crude and contained some inaccuracies and needs a complete makeover showing testing done on the bike as well as when the rotor and stator are removed