-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is it my turn? Anything to do with lathes, mills and other shop tools

Exactly!

Compound still moving a little, tho not nearly as bad. Needed to broach an internal keyway in a sleeve, don't have a broach.

There's a trick using a parting tool and a lathe. Mount the parting tool sideways, mount the piece in the chuck. With the lathe OFF and the back gear in to lock the spindle in position, use the saddle to drive the cutoff tool through the piece and advance it a couple of thousands after each pass.

Slow...Very, VERY slow...but it works.

It also spurred me to crack open the toy fund and buy a basic set of broaches...

Hi Downeaster,

like Beags was too polite to say:- "Congratulations! You have invented the shaping machine!"

OR

Mr. Bodger sez:-

Make two concentric sleeves on your lathe.

Hacksaw a groove through the inner sleeve.

Press the sleeves together & plugweld.

You can still fit a car in the garage? I'm impressed, my 2 car garage has never had a car in it since I bought the house.

24 x 48 garage. I can fit two (compact...a Corolla and a Yaris) cars in there. As long as no one opens the door on both cars simultaneously...

JimD54 made a comment a while back about "hanging a bolt in mid-air and building an airplane around it."

Well, I'm doing that with a snowblower...

Daughter had an 8/28 Crapsman with a 110v electric start Briggs and Scrapiron on it that I got on a horse trade with a sheared flywheel. Fixed that and she ran it for a couple of years but apparently the flywheel flopping around before I fixed it took out a crank seal and it leaked all the oil out and seized up.

I gave her my MTD e-start and took this one back. No future at all in rebuilding that POS Briggs with it's aluminum cylinder and no rod bearings. So I grabbed a Horror Fright Predator. Figured if I was gonna hafta retrofit things, I might as well go with MORE POWER! so I bought a 13 horse 12v e-start. Had to set the motor back a bit over an inch to get the pulleys to line up plus it has a larger mounting bolt pattern, so had to build a custom mount for it. In order to drill the holes to bolt the new motor mount to the chassis, it was easier to strip the chassis down to the frame and drill it on my press.

With the motor mounted to the chassis, reassembling the transmission was easier with the motor/chassis assembly hanging at shoulder height.

It's hanging from my Horror Fright 800# electric hoist that runs on barn door track the length of my "mechanical bay". It's been handier than a pocket on a shirt, especially since at my age I'm much more likely to sign a check than resort to brute strength and ignorance like I did 30 years ago...

Well, I'm doing that with a snowblower...

Daughter had an 8/28 Crapsman with a 110v electric start Briggs and Scrapiron on it that I got on a horse trade with a sheared flywheel. Fixed that and she ran it for a couple of years but apparently the flywheel flopping around before I fixed it took out a crank seal and it leaked all the oil out and seized up.

I gave her my MTD e-start and took this one back. No future at all in rebuilding that POS Briggs with it's aluminum cylinder and no rod bearings. So I grabbed a Horror Fright Predator. Figured if I was gonna hafta retrofit things, I might as well go with MORE POWER! so I bought a 13 horse 12v e-start. Had to set the motor back a bit over an inch to get the pulleys to line up plus it has a larger mounting bolt pattern, so had to build a custom mount for it. In order to drill the holes to bolt the new motor mount to the chassis, it was easier to strip the chassis down to the frame and drill it on my press.

With the motor mounted to the chassis, reassembling the transmission was easier with the motor/chassis assembly hanging at shoulder height.

It's hanging from my Horror Fright 800# electric hoist that runs on barn door track the length of my "mechanical bay". It's been handier than a pocket on a shirt, especially since at my age I'm much more likely to sign a check than resort to brute strength and ignorance like I did 30 years ago...

Great idea with the door track gantry.

I may have to think about doing something like that! Have the Harbor Fright Bike lift but that would add a bit to my lifting capabilities. The 68 year old back is not what it used to be!

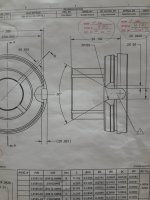

Today's project, this one's been on the list for a while...

Since I've got to turn some new acme screws for horizontal project figured I needed a way to get good, accurate angles for an acme threading tool. Got 0, 10 & 20deg for general turning tools, 45deg for chamfering, 14.5 & 30 for threading tools. We'll see if it works out.

Since I've got to turn some new acme screws for horizontal project figured I needed a way to get good, accurate angles for an acme threading tool. Got 0, 10 & 20deg for general turning tools, 45deg for chamfering, 14.5 & 30 for threading tools. We'll see if it works out.

Ho ho ho

Bet you can relate.

https://detroit.craigslist.org/mcb/tls/6770472833.html

Never seen one that looks like this. Kinda cool.

Never seen one that looks like this. Kinda cool.

Machine shop pics today.

"Motion Controller Encoder" motor couplings is what I've been making for awhile now. A variety of these very small precise components.

40+ hrs a week in these very tight work spaces. This is not really a topic to discuss at a Christmas party or at dinner, So just maybe a few of you all would enjoy this typical mornings work of tool replacement.

Both the usual insert and the very small .035" 3 fluted endmill which spins at 60,000 rpm. We don't use the electric motors max rpm of 80,000 !

Anyway, here are some pics

"Motion Controller Encoder" motor couplings is what I've been making for awhile now. A variety of these very small precise components.

40+ hrs a week in these very tight work spaces. This is not really a topic to discuss at a Christmas party or at dinner, So just maybe a few of you all would enjoy this typical mornings work of tool replacement.

Both the usual insert and the very small .035" 3 fluted endmill which spins at 60,000 rpm. We don't use the electric motors max rpm of 80,000 !

Anyway, here are some pics

Attachments

-

20181219_075022.jpg117 KB · Views: 169

20181219_075022.jpg117 KB · Views: 169 -

20181219_070954.jpg162.5 KB · Views: 202

20181219_070954.jpg162.5 KB · Views: 202 -

20181219_070605.jpg162.1 KB · Views: 165

20181219_070605.jpg162.1 KB · Views: 165 -

20181219_070307.jpg111.3 KB · Views: 190

20181219_070307.jpg111.3 KB · Views: 190 -

20181219_070356.jpg191.6 KB · Views: 187

20181219_070356.jpg191.6 KB · Views: 187 -

20181219_072120.jpg167.3 KB · Views: 175

20181219_072120.jpg167.3 KB · Views: 175 -

20181219_074544.jpg138.7 KB · Views: 165

20181219_074544.jpg138.7 KB · Views: 165 -

20181219_073750.jpg132.9 KB · Views: 179

20181219_073750.jpg132.9 KB · Views: 179

But but nobody understands me.

Know THAT feeling. Man that is some incredable work!

Know THAT feeling. Man that is some incredable work!

"Machinist" hmm, you mean you do this ?

So does this make me a machinist? Yea that is me with the arrow pointing to my head!

Way back in March of 1990!

That's one big Tonka toy!So does this make me a machinist? Yea that is me with the arrow pointing to my head!

View attachment 131770

Way back in March of 1990!

Right on, Now that must have been FUN !Yea that is me with the arrow pointing to my head!

Similar threads

- Replies

- 9

- Views

- 912

- Replies

- 24

- Views

- 7K