I've got a problem. Wake up America.

The new main jets look fine. (I did have a slight episode when I saw the "flats" on what I thought was the main jet.)

But the other jets are surely wrong?

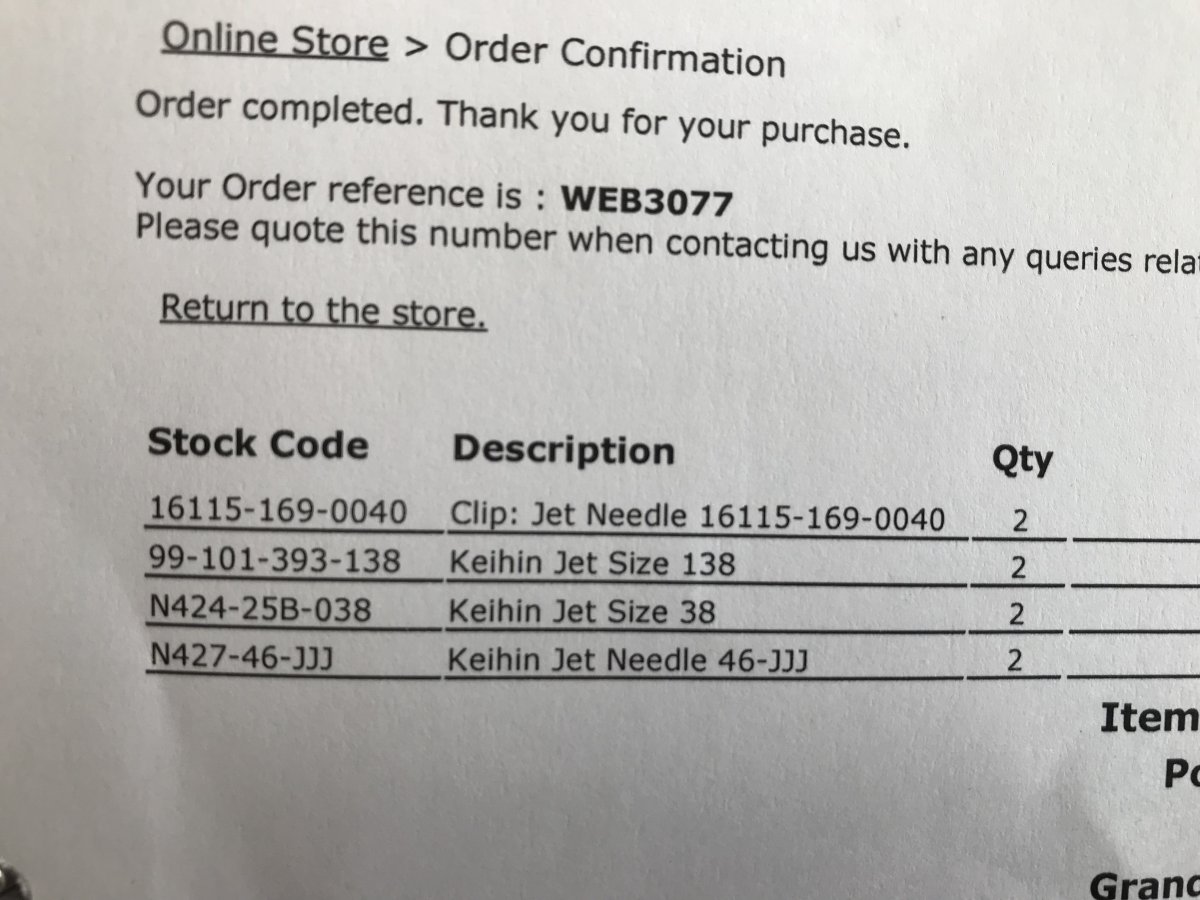

This is what I ordered. Has the supplier screwed up or have I?

N424 - 25B and then the size … 038

I've searched the EX500 thread and its mentioned a couple of times.

Have I got the wrong jet out? I can't see anything else brass with a slot.

The new main jets look fine. (I did have a slight episode when I saw the "flats" on what I thought was the main jet.)

But the other jets are surely wrong?

This is what I ordered. Has the supplier screwed up or have I?

N424 - 25B and then the size … 038

I've searched the EX500 thread and its mentioned a couple of times.

Have I got the wrong jet out? I can't see anything else brass with a slot.