@kopcicle tells me this is just a northerners thing but split standpipes are a common find on old bikes I'm fixing up.

Please forgive my sins as this is a Honda petcock but the same will work on your Yamaha.

I had already attempted a wrap with thin copper wire and solder but this pipe was ROUGH had 3 or 4 splits down most of it's length.

I had spent about 45 minutes digging out guck and making the riveted petcock work again. So really wanted the stand pipe to work.

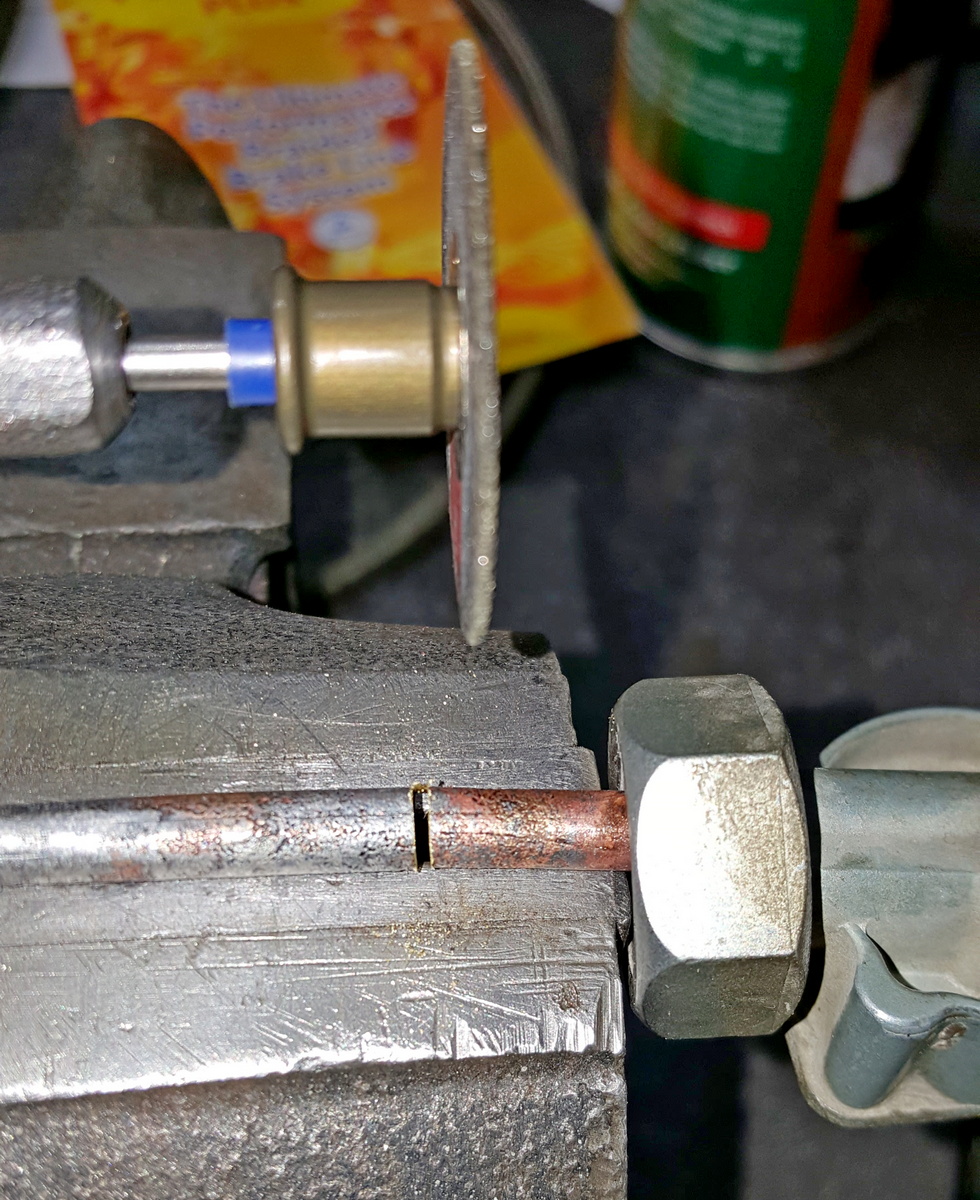

Cut it down to a stub using an abrasive cut off wheel, reduces stress, a tubing cutter or hand hacksaw might be too hard on the fragile original tube.... another plug for the dremel quick mount abrasive wheel set.

I've tried this before but finding a piece of copper tube that matches the OD of the standpipe is tough. This time the light bulb came on. EXPAND a slightly small copper tube.

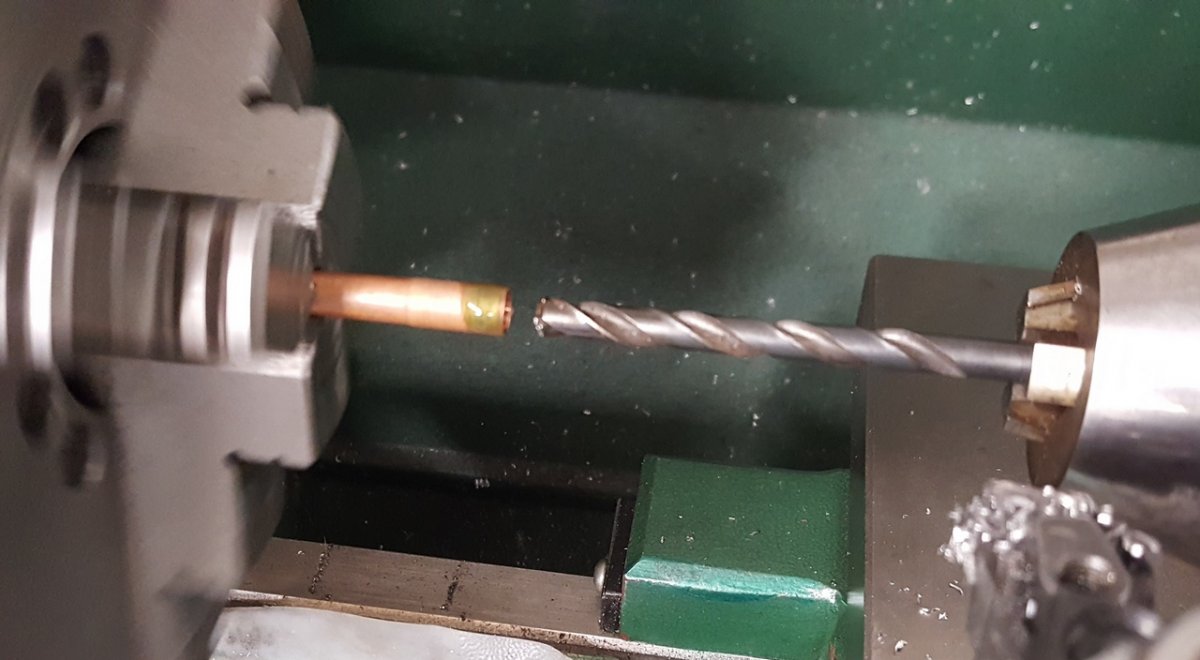

Done in the lathe, running in REVERSE, a bit of lube. Not trying to drill out the id but rather expanding it to slip over the stump of the existing standpipe. Selected a drill bit to match the standpipe OD, turned the lathe slowly in reverse and fed in the bit, it went easy as can be. You can see the expansion is already done in the pic. I think you could do this chucking the tubing in a battery drill and clamping the bit in a vice.

Cleaned both the pipes in and out with acetone, used plumbers tinning flux, which already has solder mixed with the flux, applied sparingly with a brush to both inside and outside of tubes, assembled, heated with a propane torch until the flux just turned silver, quickly cooled the petcock in water.

Done!

Then cut to length, measured before I started cutting

Please forgive my sins as this is a Honda petcock but the same will work on your Yamaha.

I had already attempted a wrap with thin copper wire and solder but this pipe was ROUGH had 3 or 4 splits down most of it's length.

I had spent about 45 minutes digging out guck and making the riveted petcock work again. So really wanted the stand pipe to work.

Cut it down to a stub using an abrasive cut off wheel, reduces stress, a tubing cutter or hand hacksaw might be too hard on the fragile original tube.... another plug for the dremel quick mount abrasive wheel set.

I've tried this before but finding a piece of copper tube that matches the OD of the standpipe is tough. This time the light bulb came on. EXPAND a slightly small copper tube.

Done in the lathe, running in REVERSE, a bit of lube. Not trying to drill out the id but rather expanding it to slip over the stump of the existing standpipe. Selected a drill bit to match the standpipe OD, turned the lathe slowly in reverse and fed in the bit, it went easy as can be. You can see the expansion is already done in the pic. I think you could do this chucking the tubing in a battery drill and clamping the bit in a vice.

Cleaned both the pipes in and out with acetone, used plumbers tinning flux, which already has solder mixed with the flux, applied sparingly with a brush to both inside and outside of tubes, assembled, heated with a propane torch until the flux just turned silver, quickly cooled the petcock in water.

Done!

Then cut to length, measured before I started cutting