-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Running badly; thoughts?

- Thread starter delagem

- Start date

Went back to the top listened to the start run video a few times,

thoughts.

we haven't seen the whole bike, carbs, air filters, exhaust etc.

Video sound is not the greatest, but my 1000 mile diagnosis is that it sounds like it's going lean.

idle sounds great.

your pickup test seems like they are fine.

can you "horse the RPM up" with choke or cadging the throttle? Are both intake air barbs capped? might remove the vacuum line from the LH carb, cap and fire with petcock in prime.

Are there "extra fuel filters? Any rust in tank?

try to get it past 2500 rpm, ideally let it stall trying, pull the plugs, what do you see?

open the float bowl drains run a line to a clean container turn petcock to prime watch fuel flow. look for good flow, crud. Then it's into the carbs.

From the carb tech thread http://www.xs650.com/threads/carbs-carburetors.43/

A thread devoted specifically to BS34's as found on the XS650 80-84

http://www.xs650.com/threads/carburettors-from-the-grave.34737

The BS34's have a small "final" fuel screen inside the carb body above the float valve seat!

Rather obscure but exhaust blockage? there are occasional instances of a collapsed stock inner exhaust pipe wall, to be honest I no longer remember what years this happened on.

thoughts.

we haven't seen the whole bike, carbs, air filters, exhaust etc.

Video sound is not the greatest, but my 1000 mile diagnosis is that it sounds like it's going lean.

idle sounds great.

your pickup test seems like they are fine.

can you "horse the RPM up" with choke or cadging the throttle? Are both intake air barbs capped? might remove the vacuum line from the LH carb, cap and fire with petcock in prime.

Are there "extra fuel filters? Any rust in tank?

try to get it past 2500 rpm, ideally let it stall trying, pull the plugs, what do you see?

open the float bowl drains run a line to a clean container turn petcock to prime watch fuel flow. look for good flow, crud. Then it's into the carbs.

From the carb tech thread http://www.xs650.com/threads/carbs-carburetors.43/

A thread devoted specifically to BS34's as found on the XS650 80-84

http://www.xs650.com/threads/carburettors-from-the-grave.34737

The BS34's have a small "final" fuel screen inside the carb body above the float valve seat!

Rather obscure but exhaust blockage? there are occasional instances of a collapsed stock inner exhaust pipe wall, to be honest I no longer remember what years this happened on.

Last edited:

As found; cracked vacuum barb covers letting in air.

It's popular to grab spray carb cleaner; spritz front of carbs, intakes while motor is idling, motor speeding up indicates air leaks, commonly found; cracked intake rubber manifold. bad/missing head/manifold gasket, leaking throttle shaft seals.

The fuel filter and a rather typical bad float valve o-ring.

If intake is pretty much stock, the needle jet shim washer mod is de-rigueur.

Cheesy pod filters block ports on intakes causing run issues.

check that the jetting is stock, or reasonable for exhaust changes.

Are the rubber plugs on the pilot jets?

pilot jet, needle jet, blocked, dirty, plugged.

Last edited:

Is the choke lever off, "chokes" (enricheners) fully seated? The slides won't rise with the choke on or leaking.

The needle jet is often overlooked and not removed for inspection/cleaning. My buddy swore to me up and down that he had thoroughly cleaned his carbs, totally taken them apart, and replaced practically every part in them. When I finally got a look at them, I found he hadn't touched the needle jets. When I removed them, they were black as the ace of spades and all gummed up down the sides. He was getting just fuel through the jet and no air was being added through the side bleed holes.

The main jet and washer holds it in place, VERY carefully tap it up and out of the carb body tricky work, there is a pin and slot that keep it oriented in the carb body don't start banging on the pin, varnish can have it stuck in there pretty good. If it's fighting you; use a heat gun to soften the varnish, then a copper wire through every blasted one of those little holes till daylight shows plain and round through em all. LOL

Last edited:

I went to shoot a video of the bike stumbling at 2,400 rpm and full throttle, and get a plug chop while doing so. (I know that's not a real plug chop, but it'd show how the bike was running at least).

So first I cleaned all the carbon off the plugs. They are new looking on the outside, but had a lot of black soot on them. I REALLY scrubbed them. Brake cleaner, brass wire brush, ether, more wire brushing, blow dry. Put the plugs in, zoom! Right up to 6,000. Still stumbling all over itself, but running.

I haven't touched the carbs. According to my son, the bike ran well when he bought it a few weeks ago. Tank looks very good inside. I think at this point that going thru the carbs properly will be my next move.

Funny, my first post in this thread:

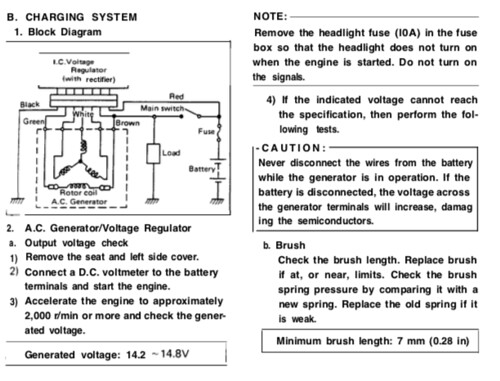

I think that charge issue was a red herring. It had me looking for electrical due to an imaginary charge issue. I found the following statement in the service manual:

Screen Shot 2018-06-03 at 12.58.41 PM by michael delage, on Flickr

Screen Shot 2018-06-03 at 12.58.41 PM by michael delage, on Flickr

The voltage test is only valid if the headlight fuse is pulled!

I've got just the tool for those jets:

WYPO_4.MZEU1_bf0dc2192c by michael delage, on Flickr

WYPO_4.MZEU1_bf0dc2192c by michael delage, on Flickr

So first I cleaned all the carbon off the plugs. They are new looking on the outside, but had a lot of black soot on them. I REALLY scrubbed them. Brake cleaner, brass wire brush, ether, more wire brushing, blow dry. Put the plugs in, zoom! Right up to 6,000. Still stumbling all over itself, but running.

I haven't touched the carbs. According to my son, the bike ran well when he bought it a few weeks ago. Tank looks very good inside. I think at this point that going thru the carbs properly will be my next move.

Funny, my first post in this thread:

So, what am I missing? I know 90% of all electrical are carburetor related, but the fact that the battery doesn't charge has to be significant, right? Any suggestions?

Michael

I think that charge issue was a red herring. It had me looking for electrical due to an imaginary charge issue. I found the following statement in the service manual:

The voltage test is only valid if the headlight fuse is pulled!

I've got just the tool for those jets:

Actually, the needle jet taps into the carb body's main bore from the bottom of the carb for removal. It doesn't come out of the bottom of the carb, it comes out of the top.

Buy new spark plugs, sounds like yours are badly carbon fouled. The standard BP7ES NGK these bikes run can be had right from most auto parts stores for about $2 each. Buy a 4-pack. Check and close the gaps up to about .030". They'll come gapped much bigger than that for car use but our old bikes can't fire big gaps like that. In fact, check the plugs you have now, maybe they're gapped too big too.

Buy new spark plugs, sounds like yours are badly carbon fouled. The standard BP7ES NGK these bikes run can be had right from most auto parts stores for about $2 each. Buy a 4-pack. Check and close the gaps up to about .030". They'll come gapped much bigger than that for car use but our old bikes can't fire big gaps like that. In fact, check the plugs you have now, maybe they're gapped too big too.

Last edited:

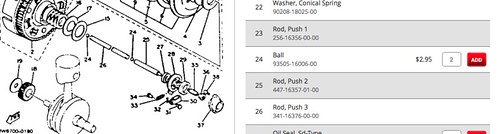

Putting things back together. Better check my balls. 1,2,...3? Huh?

IMG_1114 by michael delage, on Flickr

IMG_1114 by michael delage, on Flickr

From the fiche for 1983 Yamaha XS650SK, quantity 2:

Screen Shot 2018-06-03 at 1.15.39 PM by michael delage, on Flickr

Screen Shot 2018-06-03 at 1.15.39 PM by michael delage, on Flickr

Looks like somebody's attempt at fixing the clutch. Guessing the frictions are going to be under spec... Ugh.

From the fiche for 1983 Yamaha XS650SK, quantity 2:

Looks like somebody's attempt at fixing the clutch. Guessing the frictions are going to be under spec... Ugh.

Maybe not. There actually is a third ball, inside the worm. It's not shown on the drawings because it it considered a part of that assembly, actually crimped in place. But, over time, the pushrod wears the crimps away and the ball can come out.

FWIW I don't believe in steel wire jet cleaning too easy to remove brass changing design size.

5t I had caught and corrected my mis-statement re needle jet removal.

5t I had caught and corrected my mis-statement re needle jet removal.

Heavy soot on plugs with BS34's points at leaking float valve, o-rings. These carbs are set pretty lean from the factory. Regardless; off with it's carbs is wise at this point.

Last edited:

Yes, good. I don't like poking jets either. I find a good soaking and properly directed compressed air (with the right blow gun tip) usually does the trick. The tapered rubber tip is what I use most but I also have an assortment of needle tips .....

As expected, re-running the test with the headlight fuse pulled, at idle is 12.8v, and at 2,000rpm is 13.8; much closer to the 14.2-14.8v specified in the manual. I think we're good here.

As a side note: one brush appears OEM, one is Chiwanese aftermarket. What a difference in spring tension! Chiwanese spring is easily 1/2 the tension of the OEM looking brush. I wouldn't be surprised if that alone accounts for the missing 0.7 of a volt I'm still seeing.

Timing isn't too far off. Here is idle, 1,200rpms; should be inside the horseshoe. We are just a smidge outside. Probably could live with it, might slot the pickup screw holes to make it "right". Dunno. Thoughts? It's obviously not the primary issue here.

IMG_1116 by michael delage, on Flickr

IMG_1116 by michael delage, on Flickr

I like those burner tip cleaners because I deal a lot with KTM carburetors, and their ridiculously small sized idle jets; I've got an ultrasonic tank if they aren't that bad. Honestly, the long term plan was to throw a set of 39 FCR's into this bike in any case.

Thank you for the help, everyone! Never would have made it this far without the ideas here. To be continued...

As a side note: one brush appears OEM, one is Chiwanese aftermarket. What a difference in spring tension! Chiwanese spring is easily 1/2 the tension of the OEM looking brush. I wouldn't be surprised if that alone accounts for the missing 0.7 of a volt I'm still seeing.

Timing isn't too far off. Here is idle, 1,200rpms; should be inside the horseshoe. We are just a smidge outside. Probably could live with it, might slot the pickup screw holes to make it "right". Dunno. Thoughts? It's obviously not the primary issue here.

I like those burner tip cleaners because I deal a lot with KTM carburetors, and their ridiculously small sized idle jets; I've got an ultrasonic tank if they aren't that bad. Honestly, the long term plan was to throw a set of 39 FCR's into this bike in any case.

Thank you for the help, everyone! Never would have made it this far without the ideas here. To be continued...

Last edited:

Does anyone have a good idea for adding an inline fuel filter? Yamaha have done a commendable job of running a line direct from the fuel tap to the carb "T". But there's just no slack for an inline filter. Does anyone have a photo of how to add one?

If you are going to insist it go between the carbs you may find a 90-degree filter works better.

If you don't mind it being in the open or outside, turn the "t" down and come in from the bottom outside.

That leaves the filter in a position easier to observe and change.

Sorry, I don't have pics available. I think NJ posted some several years back.

If you don't mind it being in the open or outside, turn the "t" down and come in from the bottom outside.

That leaves the filter in a position easier to observe and change.

Sorry, I don't have pics available. I think NJ posted some several years back.

Thought I'd bring this back to the top, with a resolution.

It turns out that the aftermarket alternator rotor (MikesXS I believe) fitted by the previous owner was creating enough interference with the ignition trigger magnet to prevent the bike from running properly.

I fitted one of Jim's OEM rotor rewinds (Thank you Jim!) and the problem seems to have been resolved. Jim's theory, I believe, is that there isn't much copper in the outer face of the rotor. This copper acts as a shield. The lack of it allows the magnetic field from the rotor to interfere with the trigger magnet. The problem would eventually go away when the bike ran for a few minutes, and the battery stopped demanding so much amps to recharge.

Thank you to everyone for your help with this!

Now where did I leave that sidecar...?

It turns out that the aftermarket alternator rotor (MikesXS I believe) fitted by the previous owner was creating enough interference with the ignition trigger magnet to prevent the bike from running properly.

I fitted one of Jim's OEM rotor rewinds (Thank you Jim!) and the problem seems to have been resolved. Jim's theory, I believe, is that there isn't much copper in the outer face of the rotor. This copper acts as a shield. The lack of it allows the magnetic field from the rotor to interfere with the trigger magnet. The problem would eventually go away when the bike ran for a few minutes, and the battery stopped demanding so much amps to recharge.

Thank you to everyone for your help with this!

Now where did I leave that sidecar...?

I'm glad the rotor fixed. If it were me.... I'd revisit the TDC mark and check the timing again now that you have a known good timing mark to go by. Never trusted those Chinese timing marks....

Similar threads

- Replies

- 6

- Views

- 502

- Replies

- 4

- Views

- 889