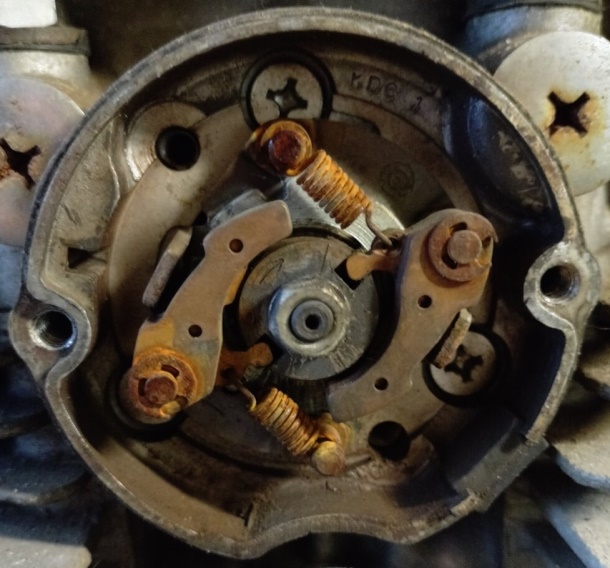

Looks like you've got it squared away now. Since the advance backing plate is just raw steel, you'll want to keep it lubed for protection against rust. I just brush a light coating of motor oil on it. Not too much, just make it shine. Any excess will just be flung off by centrifugal force as the unit spins and make a mess inside the housing. The first time I service one of these and have the weights off, I'll lightly grease the pivot posts when putting the weights back on. After that, to keep things lubed, I'll apply a little foaming chain lube to the posts after a ride while the bike is hot (better penetration). I also put a few drops on the springs as well. You're looking to avoid this scenario, lol .....

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

Advance bob weights and springs question?

- Thread starter Its been a long time

- Start date