CeeAnton

XS650 Member

I have been re-assembling my bored, rephased XS650SJ. I have hit snag while degreeing the cam, and want to ask your advice.

Background: Valve job, head re-surfacing, and boring (to 700) by Hoos. 447 crank and cam 277 rephased by Hugh's. New pistons, rings, cam chain, cam guides (both). Head torqued down to spec +2lbs.

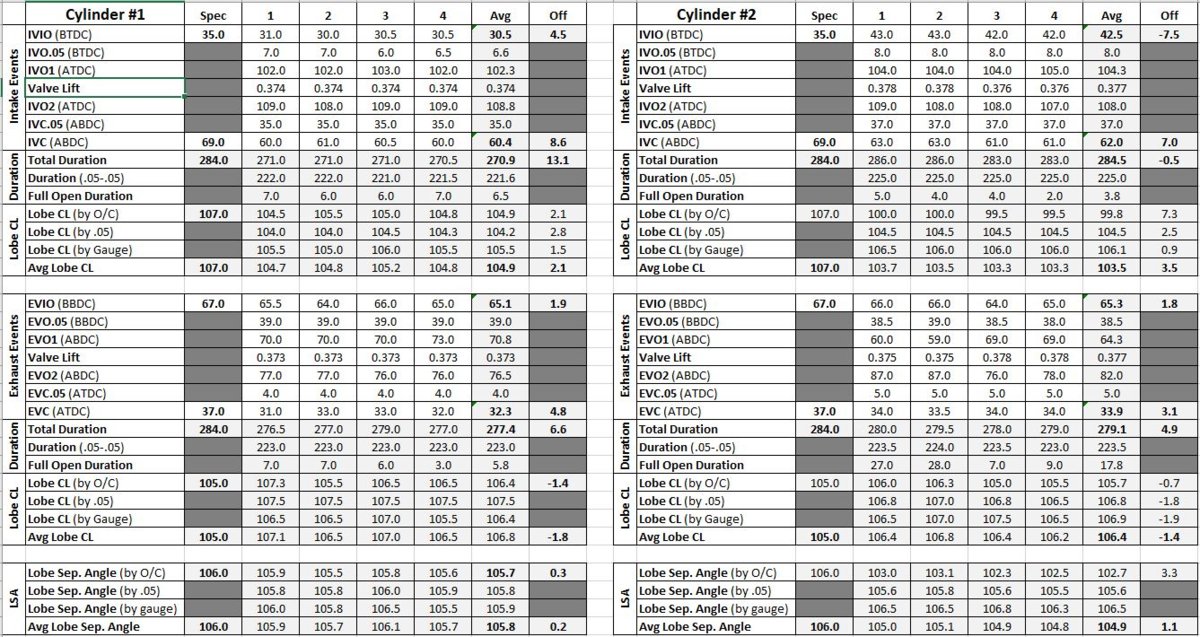

Procedure: TDC'd each side with a piston stop, inspection valve lash set to .012" (and verified/adjusted by dial indicator to make sure it was dead on.) For each valve: to account for any error (procedural or observational), I measured everything (degrees at initial valve opening/closing, .05 open/close, full open (where the gauge appears to stop, and then starts to move back down)) three times. Then I moved the dial indicator to different part of the valve retainer and re-measured three more times. I threw out the two measurements that were the most off the curve, averaged the four that were left, ran some calculations, and compared that average to the Clymer manual's spec numbers. I was pretty meticulous. So I'm not sure how some of the numbers are way off spec, and others are almost dead on, short of 1 odd cam lobe. (Attaching a pic of my results.)

1. Which of these numbers do I need to worry about?

2. How can I correct without throwing everything else off? It looks like I may need to the advance the cam 2 degrees...or should I bother for 2 degrees? I REALLY don't want to pull the rocker cover, if I don't have to.

3. I'm thinking that if I tighten the lash on Cylinder #2's IV 2-3 hundredths, and Cylinder #1's IV by a hundredth, it would pull the Valve Lift, Initial Open, and Fully closed numbers closer to spec without affecting Lobe CL. Does that sound right?

4. I can't find a spec on the valve lift for IV and EV. Does anyone know that those should be?

5. Do you see anything else here I should worry about?

Thanks all!!

Background: Valve job, head re-surfacing, and boring (to 700) by Hoos. 447 crank and cam 277 rephased by Hugh's. New pistons, rings, cam chain, cam guides (both). Head torqued down to spec +2lbs.

Procedure: TDC'd each side with a piston stop, inspection valve lash set to .012" (and verified/adjusted by dial indicator to make sure it was dead on.) For each valve: to account for any error (procedural or observational), I measured everything (degrees at initial valve opening/closing, .05 open/close, full open (where the gauge appears to stop, and then starts to move back down)) three times. Then I moved the dial indicator to different part of the valve retainer and re-measured three more times. I threw out the two measurements that were the most off the curve, averaged the four that were left, ran some calculations, and compared that average to the Clymer manual's spec numbers. I was pretty meticulous. So I'm not sure how some of the numbers are way off spec, and others are almost dead on, short of 1 odd cam lobe. (Attaching a pic of my results.)

1. Which of these numbers do I need to worry about?

2. How can I correct without throwing everything else off? It looks like I may need to the advance the cam 2 degrees...or should I bother for 2 degrees? I REALLY don't want to pull the rocker cover, if I don't have to.

3. I'm thinking that if I tighten the lash on Cylinder #2's IV 2-3 hundredths, and Cylinder #1's IV by a hundredth, it would pull the Valve Lift, Initial Open, and Fully closed numbers closer to spec without affecting Lobe CL. Does that sound right?

4. I can't find a spec on the valve lift for IV and EV. Does anyone know that those should be?

5. Do you see anything else here I should worry about?

Thanks all!!