XS650D

XS650 Junkie

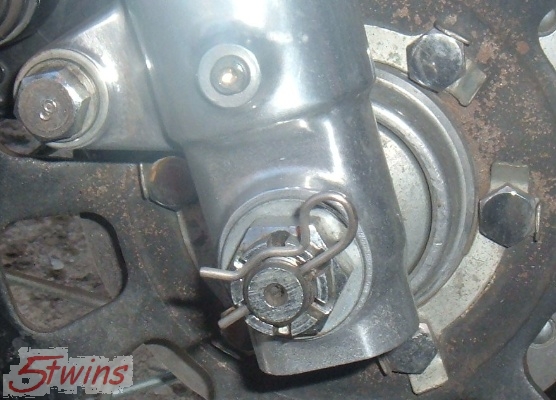

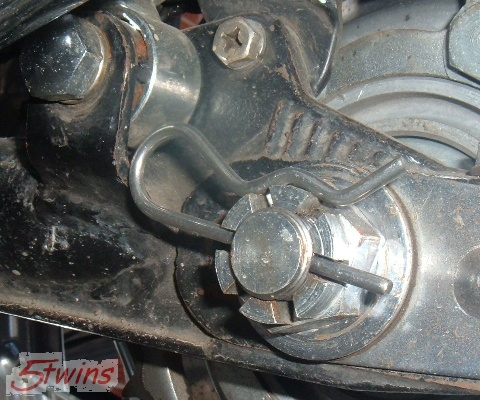

Just installed new tires and rear brake pads, pulled the rear brake pivot lever from the drum

to Lubricate when replacing pads and forgot to mark the location.Ive got everything hooked back up

but unsure if there is a certain setting for the pivot lever.There no setting mark.I have approx 1/2"off threads

showing at the end of the adjustment rod with approx 1" off freeplay at the Foot pedal.I guess I was

wondering if there was an optimum setting for best leverage.I realize the bushing in the lever pivots to account for adjustment as brake pads wear.Also while I'm at it is the bar that attaches to the drum and runs to the centre of bike,cantrecall the name.Should I be bolted tight or does it pivot as the suspension moves .

I guess its a brace of some kind.

to Lubricate when replacing pads and forgot to mark the location.Ive got everything hooked back up

but unsure if there is a certain setting for the pivot lever.There no setting mark.I have approx 1/2"off threads

showing at the end of the adjustment rod with approx 1" off freeplay at the Foot pedal.I guess I was

wondering if there was an optimum setting for best leverage.I realize the bushing in the lever pivots to account for adjustment as brake pads wear.Also while I'm at it is the bar that attaches to the drum and runs to the centre of bike,cantrecall the name.Should I be bolted tight or does it pivot as the suspension moves .

I guess its a brace of some kind.