nhsteve

XS650 Addict

I just finished a rebuild on a '74. Bought not running, no compression on RH cylinder. Pull motor, rebuild top end (long story in there, not pertinent to my 'issue'), reassemble. No major headaches during rebuild. As I had suspicions of 'stuff' in the base (none found), I split the cases and vapor blasted cases, cylinder, head, cam cover, etc. (had to remove shift drum assembly to do this).

Reassembly of all this held no drama. Continue on with rebuild. Lots of new bits (it is to be my son's bike, so I want it solid).

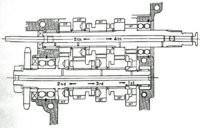

My issue: bike shifts fine between first 3 gears, any way, all day, as long as I stay in those 3. If I shift up to 4th or 5th, also no problem. Shift 5th to 4th, no problem. Shift 4th to 3rd, no problem. At this point, the shifter will not go from 3rd to 2nd. At all. Period. I had to get to the side of the road, shut it off, play with the shifter by hand, get it back into 2nd, then neutral, and I was off again. Shift distances "A" and "AA" shown in the manual are equal, things are tight.

I can duplicate this on the lift/centerstand by moving the back wheel (1" chain slack) and shifting between the first 3 gears fine. Shifting up never seems to be a problem. It is only from 3rd to 2nd that seems to be an issue. Suspecting a bent 3rd gear shift fork I have replaced it, but the original barely seems marked at all. Any damage is certainly not obvious.

Moving the shift drum assembly with no gearshafts in place I can shift the first 3 positions ok. When I push and go further, something binds so bad that I need to disassemble things again to free them up.

Sorry for the long explanation. This is really kicking me at the moment. Anyone seen this? Bent shift drum? Shift rod?

I have a later motor for parts I intend to disassemble and compare.

Reassembly of all this held no drama. Continue on with rebuild. Lots of new bits (it is to be my son's bike, so I want it solid).

My issue: bike shifts fine between first 3 gears, any way, all day, as long as I stay in those 3. If I shift up to 4th or 5th, also no problem. Shift 5th to 4th, no problem. Shift 4th to 3rd, no problem. At this point, the shifter will not go from 3rd to 2nd. At all. Period. I had to get to the side of the road, shut it off, play with the shifter by hand, get it back into 2nd, then neutral, and I was off again. Shift distances "A" and "AA" shown in the manual are equal, things are tight.

I can duplicate this on the lift/centerstand by moving the back wheel (1" chain slack) and shifting between the first 3 gears fine. Shifting up never seems to be a problem. It is only from 3rd to 2nd that seems to be an issue. Suspecting a bent 3rd gear shift fork I have replaced it, but the original barely seems marked at all. Any damage is certainly not obvious.

Moving the shift drum assembly with no gearshafts in place I can shift the first 3 positions ok. When I push and go further, something binds so bad that I need to disassemble things again to free them up.

Sorry for the long explanation. This is really kicking me at the moment. Anyone seen this? Bent shift drum? Shift rod?

I have a later motor for parts I intend to disassemble and compare.