ralpharama

XS650 Member

Hi as I mentioned in an earlier thread, I am restoring an XS650 engine that has been the victim of some serious abuse.

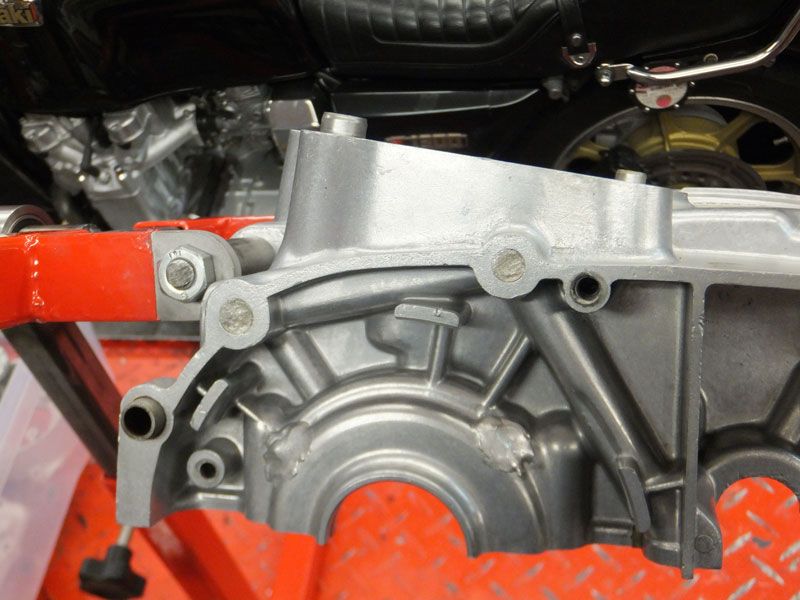

There are a number of holes in the top crankcase that look as if they have been filled with an epoxy putty and I'm wondering if they should have been. I have taken a few pix of them:-

On the first pic the holes look as if they were threaded holes?

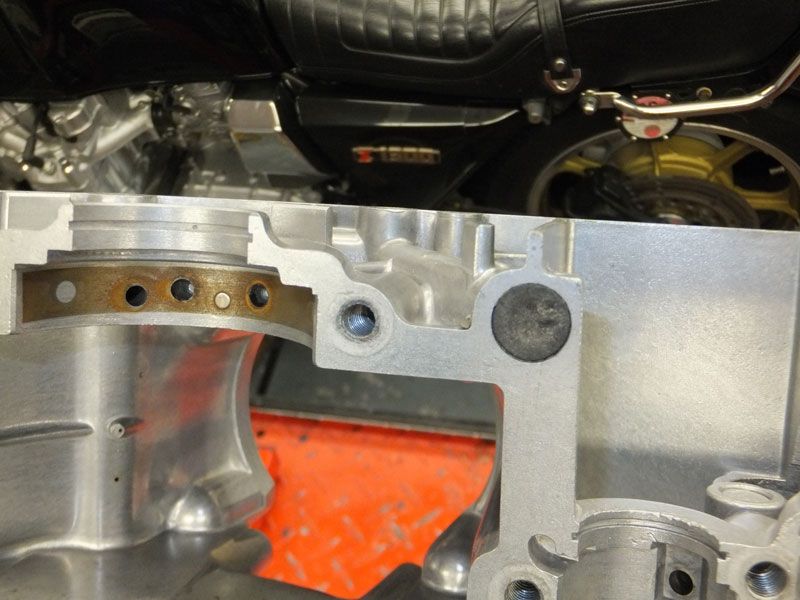

Also in the bottom case there appears to be what looks like and engine mounting bolt that has been sawn off

Should that be there? The engine was fitted in an old Uncle Bunts hard tail frame so it's possible it's not needed, but if that's the case why leave it?

Any pointers on these would be appreciated.

Cheers

There are a number of holes in the top crankcase that look as if they have been filled with an epoxy putty and I'm wondering if they should have been. I have taken a few pix of them:-

On the first pic the holes look as if they were threaded holes?

Also in the bottom case there appears to be what looks like and engine mounting bolt that has been sawn off

Should that be there? The engine was fitted in an old Uncle Bunts hard tail frame so it's possible it's not needed, but if that's the case why leave it?

Any pointers on these would be appreciated.

Cheers