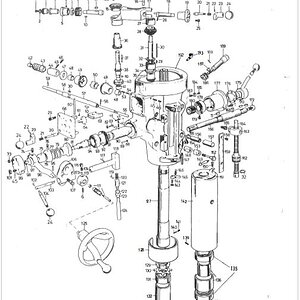

I decided to tackle the quill housing assembly next. I used the H & W assembly videos as a reference and started by installing the quill, quill sleeve (foreshadowing...) and related parts, followed by the power downfeed gears and drive components. This was more time consuming than I expected as there are several gear shafts and bevel gears that need to be installed so everything lines up while also setting the gear backlash. It's a balancing act between smoothness and minimizing backlash. It took a couple of tries, while also finding some parts that needed deburring and massaging to operate smoothly but I was eventually happy with the operation of the gears.

It doesn't look like much; the first picture is the two bevel gears which also has part of the handfeed and dog clutch. The second (upper right) is the gears located above for the three power feed speeds. Below and right of that is part of the power feed clutch which also carries one of the drive gears.

Next came the quill feed shaft, gear and the return spring. This shaft is used for both power feed, hand feed and fine hand feed. After installing and tensioning the spring, the quill would feed down about three inches and then stop, hmmmm. After a little poking around and observation and rewatching the video WITH brain engaged, it seems I installed the quill sleeve backwards and the sleeve was hitting the quill feed gear. Doh!

The sleeve is the round sheet metal part around the top of the quill. At the bottom of the picture is the cradle which is used to engage and transfer power for the power downfeed.

So... I had to remove the cradle, quill feed shaft, clutch and return spring to get the sleeve out! I flipped it around, but it still wasn't working smoothly so I had to massage it using the quill as a form and a dead blow hammer to help it back into shape and deburred all the sharp edges. I reinstalled it and it now works SMOOOTH! I reassembled everything and here we are...

Getting there, one SMALL step at a time.

It doesn't look like much; the first picture is the two bevel gears which also has part of the handfeed and dog clutch. The second (upper right) is the gears located above for the three power feed speeds. Below and right of that is part of the power feed clutch which also carries one of the drive gears.

Next came the quill feed shaft, gear and the return spring. This shaft is used for both power feed, hand feed and fine hand feed. After installing and tensioning the spring, the quill would feed down about three inches and then stop, hmmmm. After a little poking around and observation and rewatching the video WITH brain engaged, it seems I installed the quill sleeve backwards and the sleeve was hitting the quill feed gear. Doh!

The sleeve is the round sheet metal part around the top of the quill. At the bottom of the picture is the cradle which is used to engage and transfer power for the power downfeed.

So... I had to remove the cradle, quill feed shaft, clutch and return spring to get the sleeve out! I flipped it around, but it still wasn't working smoothly so I had to massage it using the quill as a form and a dead blow hammer to help it back into shape and deburred all the sharp edges. I reinstalled it and it now works SMOOOTH! I reassembled everything and here we are...

Getting there, one SMALL step at a time.

Last edited:

) pry bar 'round here somewheres. Iffn you could find a place to wedge it, you could rotate the earth backwards.

) pry bar 'round here somewheres. Iffn you could find a place to wedge it, you could rotate the earth backwards.