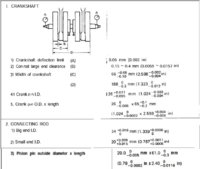

I didn't notice the assembled width dimensions in the manual, by chance do you know what they should be?

*nevermind, I didn't notice the manual shot you posted TooMany. My manual doesn't have that shot, so I'll have to measure again soon.

*nevermind, I didn't notice the manual shot you posted TooMany. My manual doesn't have that shot, so I'll have to measure again soon.

Attachments

Last edited: