The police use them to dredge for bodies in rivers and lakes.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mystery Tool - what is it?

- Thread starter nighthog

- Start date

Then they told me what it was for. The New Jersey State Police commissioned 200 of those heavy trebbles and the tackle store made some extras. The police use them to dredge for bodies in rivers and lakes.

Just another reason to stay away from NJ!

Well, you wouldn't want your lakes and rivers to fill up with dead bodies, would you?Just another reason to stay away from NJ!

The police use them to dredge for bodies in rivers and lakes.

Just another reason to stay away from NJ!

“Whadya think? We gonna stack em up in the back room? We gotta put em somewhere.”

What this Jersey town needs is a good sheriff.

Okay enough, time to get this derailed train back on track!

I tried locating a service manual online to explain this but so far no luck so this is probably going to be a rather wordy explanation, I do tend to get carried away with details at times!

I'm going to try to explain what that Mystery Tool I posted is, this one:

As I believe I mentioned before it is considered a wrench. So what do you use a wrench for? Tuning a nut, right?

I'm going to assume you people know what a spanner nut is, if not they are the ones you use to adjust the steering head bearings on your XS650. Well there are other applications and some much bigger than those little ones.

One place they have been used is to adjust the rear wheel bearings on some off-highway trucks. Picture a spanner nut that is around 8 inches outside diameter threaded on an axle housing that has a thread size of about 6 inches.

As you can imagine that would take a bit larger tool than whatever you use to adjust the steering head on the Yamaha. Also the torque needed is considerably high than I would want on the steering of said Yamaha! Now to make it fun this nut is about a foot down inside a housing with a diameter of at the most 24 inches so not easy to crank on the nut.

Well the housing this nut is down inside of is the wheel for the truck so it turns on the wheel bearing the nut is adjusting. So now you have a nut that needs to be turned and a wheel that will turn, hummmm how can these two things work to your advantage?

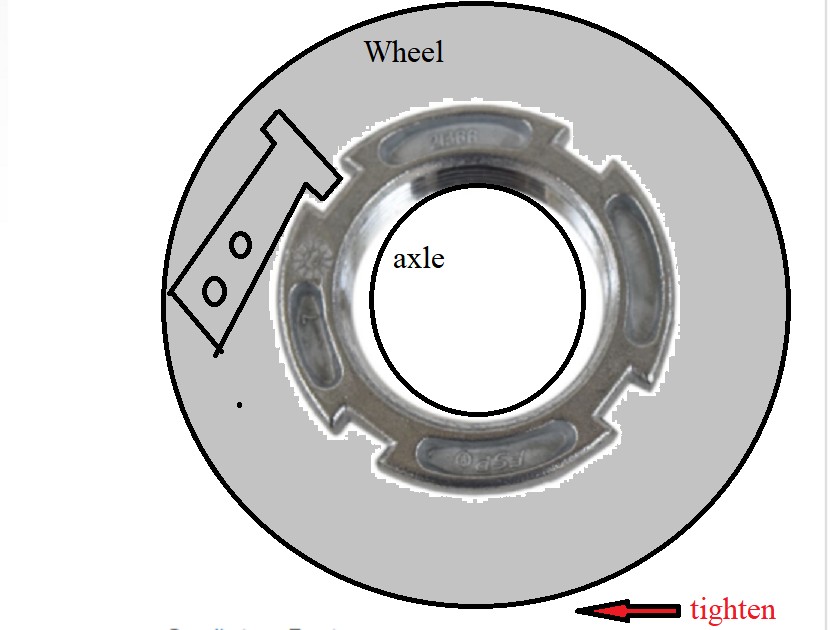

Like I said I could not find a manual online to show it but here is a rough sketch that might explain it:

Not obvious in this poor sketch is the fact that there is a threaded hole in the wheel for a 3/4 inch bolt that goes through the "wrench" and acts a a pivot point. Turning the wheel with the "wrench" bolted to it and engaged in one of the notches of the spanner nut there for turns the nut! Wheel could be turned by putting a bar in spoke like parts of the casting or wheel studs.

The reason for two holes in the "wrench" is simply because the tool was made to fit more than one size nut for different trucks.

One thing I really was hoping to find the correct service manual for was to show the "Torque spec." they gave and how they measured it. Don't recall the actual torque but the method to measure it was something like "A 180 pound man hanging on a 8 foot bar"! If I ever dig up that service manual I'll try to remember to scan that page in for here!

Almost for got to tell you what the wrench is called, it's a "Fishtail Wrench"!

I tried locating a service manual online to explain this but so far no luck so this is probably going to be a rather wordy explanation, I do tend to get carried away with details at times!

I'm going to try to explain what that Mystery Tool I posted is, this one:

As I believe I mentioned before it is considered a wrench. So what do you use a wrench for? Tuning a nut, right?

I'm going to assume you people know what a spanner nut is, if not they are the ones you use to adjust the steering head bearings on your XS650. Well there are other applications and some much bigger than those little ones.

One place they have been used is to adjust the rear wheel bearings on some off-highway trucks. Picture a spanner nut that is around 8 inches outside diameter threaded on an axle housing that has a thread size of about 6 inches.

As you can imagine that would take a bit larger tool than whatever you use to adjust the steering head on the Yamaha. Also the torque needed is considerably high than I would want on the steering of said Yamaha! Now to make it fun this nut is about a foot down inside a housing with a diameter of at the most 24 inches so not easy to crank on the nut.

Well the housing this nut is down inside of is the wheel for the truck so it turns on the wheel bearing the nut is adjusting. So now you have a nut that needs to be turned and a wheel that will turn, hummmm how can these two things work to your advantage?

Like I said I could not find a manual online to show it but here is a rough sketch that might explain it:

Not obvious in this poor sketch is the fact that there is a threaded hole in the wheel for a 3/4 inch bolt that goes through the "wrench" and acts a a pivot point. Turning the wheel with the "wrench" bolted to it and engaged in one of the notches of the spanner nut there for turns the nut! Wheel could be turned by putting a bar in spoke like parts of the casting or wheel studs.

The reason for two holes in the "wrench" is simply because the tool was made to fit more than one size nut for different trucks.

One thing I really was hoping to find the correct service manual for was to show the "Torque spec." they gave and how they measured it. Don't recall the actual torque but the method to measure it was something like "A 180 pound man hanging on a 8 foot bar"! If I ever dig up that service manual I'll try to remember to scan that page in for here!

Almost for got to tell you what the wrench is called, it's a "Fishtail Wrench"!

Nice one! I'd got as far as recognising that the holes were different diameters, but had no clue after that. That was a really good head scratcher!

I like it !Okay enough, time to get this derailed train back on track!

I tried locating a service manual online to explain this but so far no luck so this is probably going to be a rather wordy explanation, I do tend to get carried away with details at times!

I'm going to try to explain what that Mystery Tool I posted is, this one:

View attachment 138419

As I believe I mentioned before it is considered a wrench. So what do you use a wrench for? Tuning a nut, right?

I'm going to assume you people know what a spanner nut is, if not they are the ones you use to adjust the steering head bearings on your XS650. Well there are other applications and some much bigger than those little ones.

One place they have been used is to adjust the rear wheel bearings on some off-highway trucks. Picture a spanner nut that is around 8 inches outside diameter threaded on an axle housing that has a thread size of about 6 inches.

As you can imagine that would take a bit larger tool than whatever you use to adjust the steering head on the Yamaha. Also the torque needed is considerably high than I would want on the steering of said Yamaha! Now to make it fun this nut is about a foot down inside a housing with a diameter of at the most 24 inches so not easy to crank on the nut.

Well the housing this nut is down inside of is the wheel for the truck so it turns on the wheel bearing the nut is adjusting. So now you have a nut that needs to be turned and a wheel that will turn, hummmm how can these two things work to your advantage?

Like I said I could not find a manual online to show it but here is a rough sketch that might explain it:

View attachment 138415

Not obvious in this poor sketch is the fact that there is a threaded hole in the wheel for a 3/4 inch bolt that goes through the "wrench" and acts a a pivot point. Turning the wheel with the "wrench" bolted to it and engaged in one of the notches of the spanner nut there for turns the nut! Wheel could be turned by putting a bar in spoke like parts of the casting or wheel studs.

The reason for two holes in the "wrench" is simply because the tool was made to fit more than one size nut for different trucks.

One thing I really was hoping to find the correct service manual for was to show the "Torque spec." they gave and how they measured it. Don't recall the actual torque but the method to measure it was something like "A 180 pound man hanging on a 8 foot bar"! If I ever dig up that service manual I'll try to remember to scan that page in for here!

Almost for got to tell you what the wrench is called, it's a "Fishtail Wrench"!

Always brightens my day to learn something new about old tools and their application !

Thanks, Ken.

.

.

I could see where someone smacked it with a hammer to loosen a nut.Nice one! I'd got as far as recognising that the holes were different diameters, but had no clue after that. That was a really good head scratcher!

Next up......

Not sure is that JIC or SAE can't be sure if it 45º or 37º, looks to be a -06 or maybe -08 ?

37..... -08

Whada you guys got your own language? I’m still trying to figure it out.

My bad. Just double checked... it's a dash 6

I used a ruler on the screen and figured it was a little small for a -06 but might just be the resolution on my screen.37..... -08

For my first couple years working in the shop did not know of such a tool and actually made a couple homemade ones. Then one day they were unloading some odds and ends from a closed shop in another part of the company and this greasy rolled up bag fell into my hands. Did not take but a few seconds to understand what they were and in to my possession. I did leave them at the shop when I retired but kind of think that might not have been a good idea as I'm not sure anyone but me knew what they were used for. Recall that set went from -04 right up to -24 or -32

........sure is that JIC or SAE. AN.

That's right should have thought about it as you were aircraft not heavy equipment as I recall.........sure is thatJICorSAE. AN.

Any one other than Jim know what the AN stands for?

Next up......

View attachment 138492

Hi Jim,

it screws into a spark plug hole and stops the piston where the spark should happen.

Nope. Although I'll give ya that it does resemble a piston bump stop.Hi Jim,

it screws into a spark plug hole and stops the piston where the spark should happen.

Similar threads

- Replies

- 785

- Views

- 81K

- Replies

- 106

- Views

- 18K