Yeah, that’s pretty rad!

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

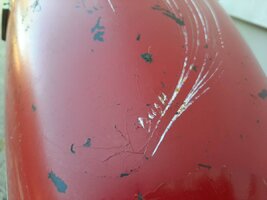

1973 Super Rustbucket Resurrection

- Thread starter DogBunny

- Start date