I'm with the sleep on it!

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

'68 BSA Victor Build..... Bloody 'el mate... You 'effin daft or sommat?!?

- Thread starter Jim

- Start date

'TT'

To make a long story short, I mowed the lawn today, sanded down a gas tank, primed another tank and some bits.... helped a neighbor tune up his car.... anything but tackle the bracket. It finally came to me. Marked it up with a sharpie and cut it to size and used some scraps of wood to hold it in position...

Tacked it in place and fitted the sidecover. A few taps here and there and I was happy.

Welding it was a real bear. There's not room to get straight on it with a tig or mig gun.... at least not with my limited skills. A stick welder would have been ideal.... unfortunately I don't have one. Finally wound up using tig. It's solid, but man is it ugly. Cleaned it up with a die grinder... just glad it won't be visible with the sidecover in place.

On to the last piece of frame repair... the tab for the sidestand. The bracket it broke off of is brazed in place. Quiet the dilemma.

Tacked it in place and fitted the sidecover. A few taps here and there and I was happy.

Welding it was a real bear. There's not room to get straight on it with a tig or mig gun.... at least not with my limited skills. A stick welder would have been ideal.... unfortunately I don't have one. Finally wound up using tig. It's solid, but man is it ugly. Cleaned it up with a die grinder... just glad it won't be visible with the sidecover in place.

On to the last piece of frame repair... the tab for the sidestand. The bracket it broke off of is brazed in place. Quiet the dilemma.

Finally wound up using tig. It's solid, but man is it ugly. Cleaned it up with a die grinder...

We in the field like to say “looks good from my house!” Enjoying the progress Jim

Another old saw, 'pretty is as pretty does.'

It's strong, functional and outta sight. Heck, I don't even weld.

It's strong, functional and outta sight. Heck, I don't even weld.

Looks good to me too.....And I dont even weld!Another old saw, 'pretty is as pretty does.'

It's strong, functional and outta sight. Heck, I don't even weld.

And if I weld it's best if you don't look at it.Looks good to me too.....And I dont even weld!

Not sure if it's just me but have never been able to see what I'm doing with either the nonauto darkening shields of the Harbor Fright auto shield. Maybe I should try working in a darker room as the refection off the back of the shields give me the biggest problem

As I get older and my eyes get worse, I try to weld in direct sunlight if possible. Try it sometime.And if I weld it's best if you don't look at it.

Not sure if it's just me but have never been able to see what I'm doing with either the nonauto darkening shields of the Harbor Fright auto shield. Maybe I should try working in a darker room as the refection off the back of the shields give me the biggest problem

Sidestand tab.

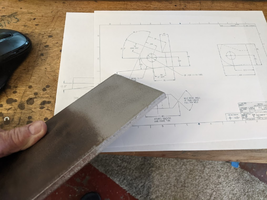

@RC4MAN took some measurements off his 250 frame (same frame for all practical purposes) and sent me some very detailed drawings of the tab. Thanks Rod!!!

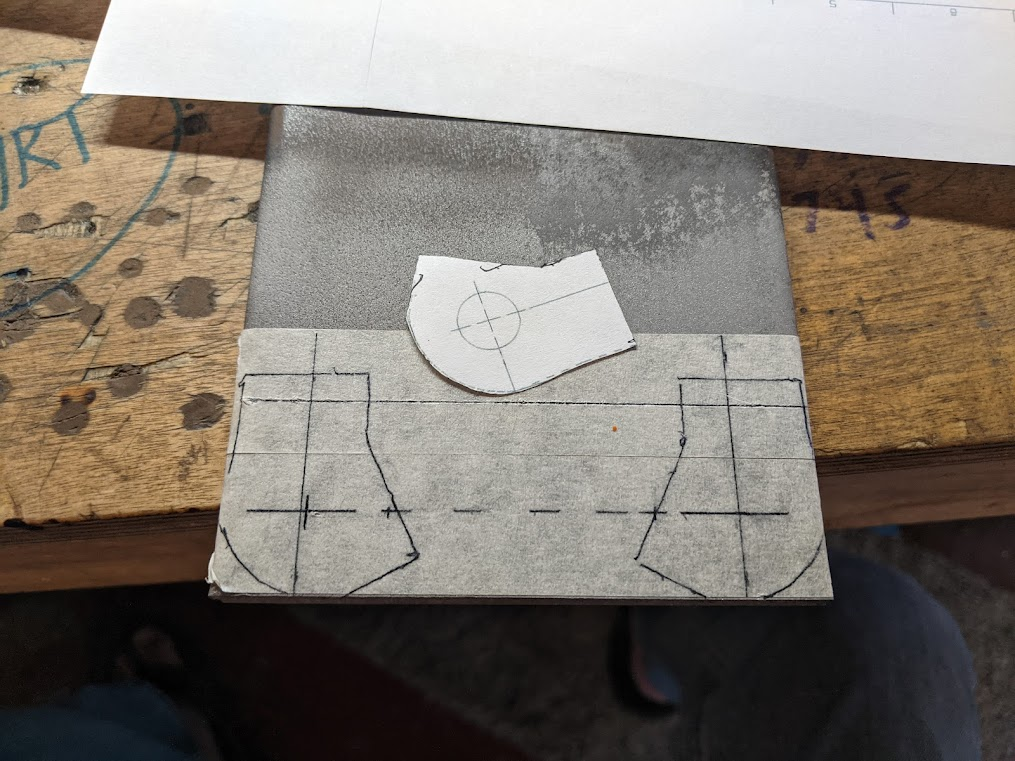

The tab is .630" thick. Couldn't find any scrap that thick and the metal shop I patronize would need to order it. Found some at .315"... exactly half thickness....

Blasted the rust off it, scaled my print 'till it matched the dimensions (84%) and cut out a pattern that I transferred to the metal.

Drilled the 7/16" holes and cut the halves out.

Vee'd the edges for good penetration.....

... and welded the two halves together.

Now I have a tab at the correct .630" thickness. Started truing up the edges... looks like it'll work just fine. Got a little more grinding and welding to do and then on to the "welding a brazed on bracket" back together dilemma....

@RC4MAN took some measurements off his 250 frame (same frame for all practical purposes) and sent me some very detailed drawings of the tab. Thanks Rod!!!

The tab is .630" thick. Couldn't find any scrap that thick and the metal shop I patronize would need to order it. Found some at .315"... exactly half thickness....

Blasted the rust off it, scaled my print 'till it matched the dimensions (84%) and cut out a pattern that I transferred to the metal.

Drilled the 7/16" holes and cut the halves out.

Vee'd the edges for good penetration.....

... and welded the two halves together.

Now I have a tab at the correct .630" thickness. Started truing up the edges... looks like it'll work just fine. Got a little more grinding and welding to do and then on to the "welding a brazed on bracket" back together dilemma....

Last edited:

Jim, I would keep a bucket of ice water around with a few rags in it. Make some marks on the bracket and frame for reference points in case it moves. When you go to tack on the bracket, wrap the brazed section in the ice cold wet rag and do your tacks. Remove the rag and see how the braze is holding up. You may not be able to run full beads, but rather oversized tack sections just to keep the heat down. May take a while but at least the bracket hopefully stays in place. Has worked for me on the job but YMMV.

Yeah, that's pretty much how I figure I'll play it.Jim, I would keep a bucket of ice water around with a few rags in it. Make some marks on the bracket and frame for reference points in case it moves. When you go to tack on the bracket, wrap the brazed section in the ice cold wet rag and do your tacks. Remove the rag and see how the braze is holding up. You may not be able to run full beads, but rather oversized tack sections just to keep the heat down. May take a while but at least the bracket hopefully stays in place. Has worked for me on the job but YMMV.

Yes, it is an A+ draft. I remember Mechanical Engineering from 1972-3 with compass, protractor, triangles, etc. My work never achieved that quality, and tedious it is. Blueprints become even more laborious.Now that is one impressive doodle!Sometimes I feel like such a hack! Btw, nice fab work Jim!

View attachment 215717

'TT'

Well, @RC4MAN 's drawings were spot on. Took a slight amount of tweaking and the sidestand fits the tab about perfect... both up and down stops make good contact. Went ahead and cut a vee in the end of it...

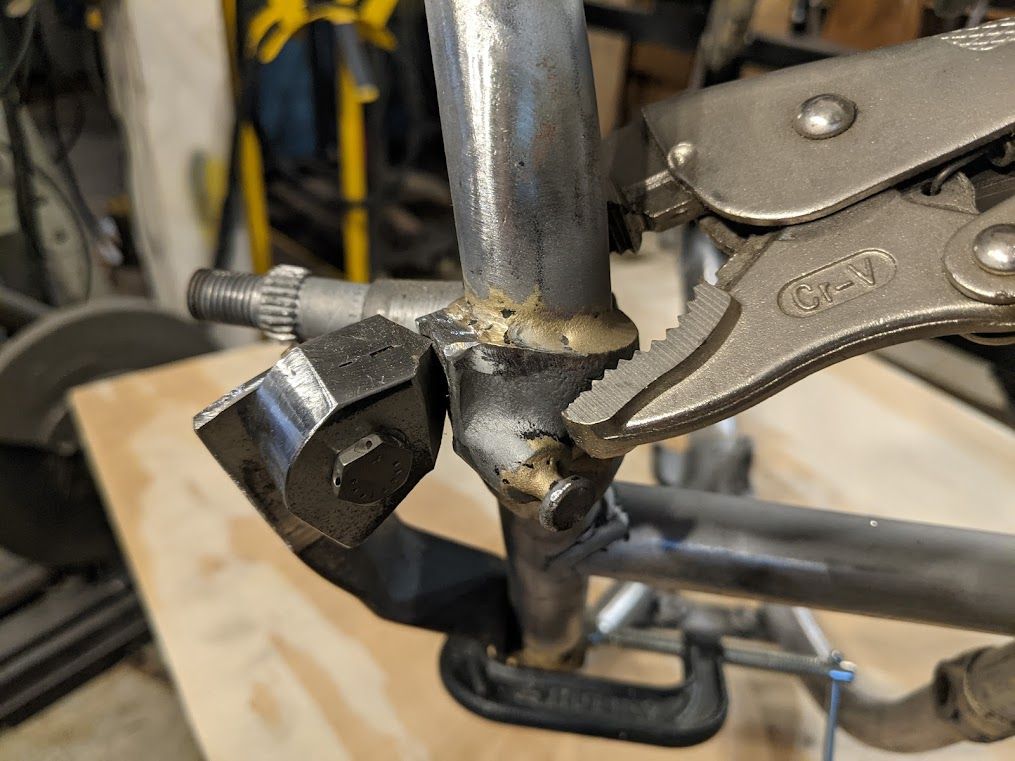

On the frame where it broke off there's a slight remnant of the original.... enough of a line I could use to line up one axis. Went above that and cut a groove in the bracket for the tab to sit in... That's camera parallax you're seeing, the lines are parallel.

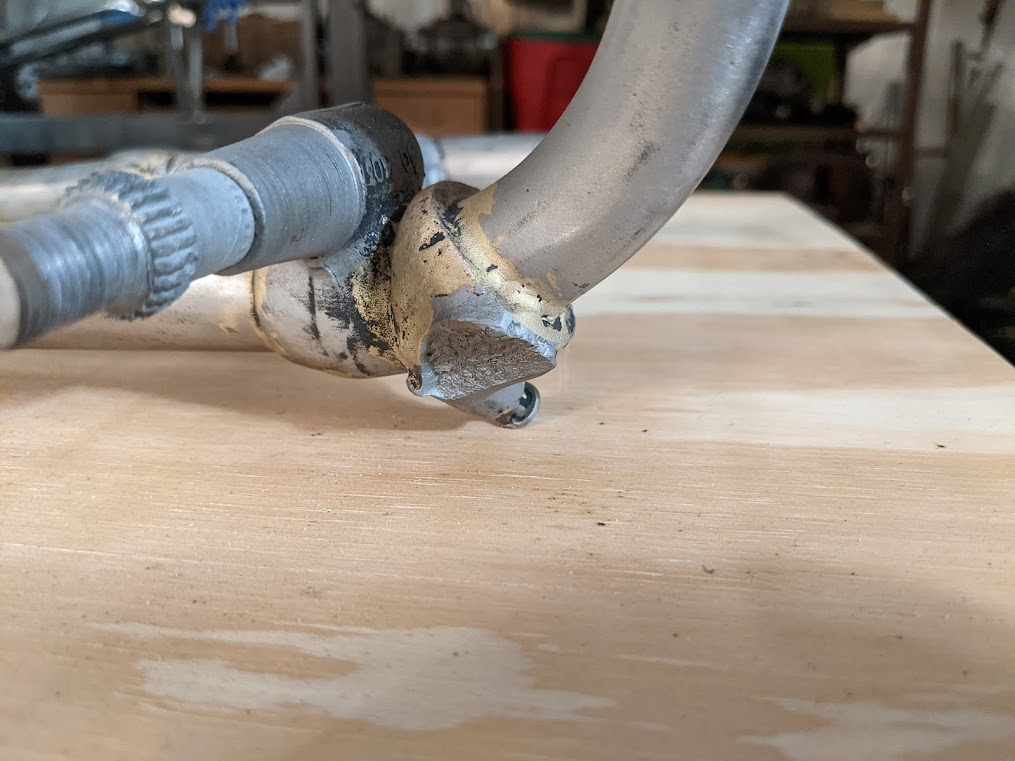

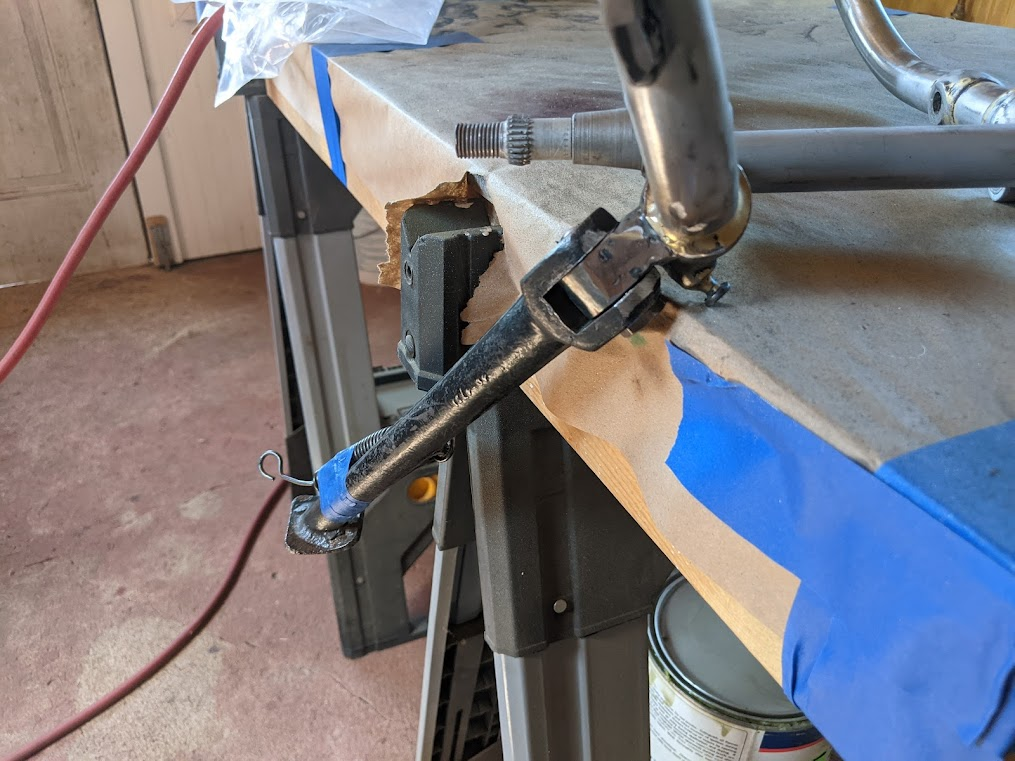

I bent up what looks like part of a Rube Goldberg contraption to hold the tab in position.

You can see in that last pic that I ground the brass back some so it didn't interfere with welding. The fore aft angle is set by the groove I cut. The Rube-ish strap sets the left right angle. Per Rod's drawings it's supposed to be 35°. I hit 35.8°.... close enough for the girls I go out with...

Also... just to hedge my bets, I clamped a vise grip on the brazed on bracket to act as a heat sink. Near as I can tell, that did it's job and then some.

First tack went right up against the brass, but never melted it.

I took my sweet time with it..... one pass and let it cool.... another pass and let it cool.

... add nauseum...

Until both sides of the vee were filled in.

Got some very slight undercutting on the last pass, but we're dealing with a 5/8" thick tab here... I can live with it.

Overall it went a lot smoother than I expected. There was a few times when I got it too hot and some brass started melting. It makes the prettiest purple flame you ever saw when it happens.... but overall I think the welds are good and solid.... and the brazed bracket never moved... I'm happy.

Like the DT frame, a lot of 50+ yr old oil started wicking out of every crevice, so I'm gonna take it out back and sandblast the bottom bits again.

But... that's the last repair on the frame. Clean it all up and it's paint time. Woohoo!!!

On the frame where it broke off there's a slight remnant of the original.... enough of a line I could use to line up one axis. Went above that and cut a groove in the bracket for the tab to sit in... That's camera parallax you're seeing, the lines are parallel.

I bent up what looks like part of a Rube Goldberg contraption to hold the tab in position.

You can see in that last pic that I ground the brass back some so it didn't interfere with welding. The fore aft angle is set by the groove I cut. The Rube-ish strap sets the left right angle. Per Rod's drawings it's supposed to be 35°. I hit 35.8°.... close enough for the girls I go out with...

Also... just to hedge my bets, I clamped a vise grip on the brazed on bracket to act as a heat sink. Near as I can tell, that did it's job and then some.

First tack went right up against the brass, but never melted it.

I took my sweet time with it..... one pass and let it cool.... another pass and let it cool.

... add nauseum...

Until both sides of the vee were filled in.

Got some very slight undercutting on the last pass, but we're dealing with a 5/8" thick tab here... I can live with it.

Overall it went a lot smoother than I expected. There was a few times when I got it too hot and some brass started melting. It makes the prettiest purple flame you ever saw when it happens.... but overall I think the welds are good and solid.... and the brazed bracket never moved... I'm happy.

Like the DT frame, a lot of 50+ yr old oil started wicking out of every crevice, so I'm gonna take it out back and sandblast the bottom bits again.

But... that's the last repair on the frame. Clean it all up and it's paint time. Woohoo!!!

Last edited:

Really good work. It's great to see somebody prepared to put so much time and thought and draw on their experience to fix up an old motorbike.

When you rock up, flip the side-stand down, step off the bike, nobody's going to say Oh look, what a good bracket! But some of us will always appreciate an old bike that would have been scrap years ago without somebody saving it.

When you rock up, flip the side-stand down, step off the bike, nobody's going to say Oh look, what a good bracket! But some of us will always appreciate an old bike that would have been scrap years ago without somebody saving it.

Spot on Raymond, the work that Jim produces and the knowledge and skills he has makes me envious. My walk through retail life didn’t endow me with his abilities (wish I did an engineering career now); but I meddle through the challenges of restoration, and call on the skilled when needed at a price. Great work Jim.

I do have a mechanical (engineering) career, and I don't possess his skills either.My walk through retail life didn’t endow me with his abilities (wish I did an engineering career now);

Nice work Jim! I think that came out great! One small part with a lot of engineering behind it! And now you won’t have to lean your bike against a tree when you park it !

Really good work. It's great to see somebody prepared to put so much time and thought and draw on their experience to fix up an old motorbike.

When you rock up, flip the side-stand down, step off the bike, nobody's going to say Oh look, what a good bracket! But some of us will always appreciate an old bike that would have been scrap years ago without somebody saving it.

Spot on Raymond, the work that Jim produces and the knowledge and skills he has makes me envious. My walk through retail life didn’t endow me with his abilities (wish I did an engineering career now); but I meddle through the challenges of restoration, and call on the skilled when needed at a price. Great work Jim.

I do have a mechanical (engineering) career, and I don't possess his skills either.

Thanks guys.... appreciate it.

Nice work Jim! I think that came out great! One small part with a lot of engineering behind it! And now you won’t have to lean your bike against a tree when you park it !

.... or a wood pile.

Well, I went to test fit the sidestand, and it didn't fit...

.

.

.

.

Nah... jus' yankin' yer chain, fit like it was made for it.

Wiped off all the oil residue that wicked it way out with some lacquer thinner, sandblasted all the bottom bits again and wiped everything down again.

I picked up some new epoxy primer that I wanted to try out. I've had real good luck with their candy's and clearcoat so.... at 140 bucks a gallon, I figured it's worth a shot....

It mixed well, has no induction time and has up to 24hrs for recoat... I like it. Two medium coats...

Forgot how much a pain in the ass frames are to paint. I'll let it sit overnight. Tomorrow is two coats gloss black and a coat of clear.

.

.

.

.

Nah... jus' yankin' yer chain, fit like it was made for it.

Wiped off all the oil residue that wicked it way out with some lacquer thinner, sandblasted all the bottom bits again and wiped everything down again.

I picked up some new epoxy primer that I wanted to try out. I've had real good luck with their candy's and clearcoat so.... at 140 bucks a gallon, I figured it's worth a shot....

It mixed well, has no induction time and has up to 24hrs for recoat... I like it. Two medium coats...

Forgot how much a pain in the ass frames are to paint. I'll let it sit overnight. Tomorrow is two coats gloss black and a coat of clear.

Last edited: