I still have my shin-gutter’ 70 Victor Special.It now hides in the corner behind a curtain so I don’t get any ideas to start kicking on it now into my 60’s. I do kick it slowly a few times so it doesn’t seize just sitting. I had not noticed this post Jim. I like it.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

'68 BSA Victor Build..... Bloody 'el mate... You 'effin daft or sommat?!?

- Thread starter Jim

- Start date

Thought that was an old Victor I saw sulking in the back of one of your pics. Nice!!

Cheers Raymond.

They're still processing the order. I'm amazed at their shipping rates.

Not sure how they stay in business givin' away shipping an' all...

View attachment 237783

I order all my lambretta parts from the UK and I’m always amazed at the shipping cost. If it’s small stuff usually between £3-5

Shipped an exhaust for £20.

Kojack

XS650 Enthusiast

Anyone ever order from these guys? Good, bad?

Ordered some bits and bobs of hardware over the weekend. Prices look good... figure it was worth a shot.

https://draganfly.co.uk/

I've ordered from them a couple of times. Very good so far. Yes, they seem to have low shipping rates for some reason.

Apparently there was a glitch in the Royal Mail matrix for a spell. That sorted, all my bits showed up. Good quality and good prices. Two thumbs up from me.

Is that Magoo66?

Yup.Is that Magoo66?

“Busted”!lol.Made a room on the other end to hide projects from her,just in case.

Attachments

Steering stem nut: Round 2.

So, jus' to recap, the original nut was buggered courtesy a previous owner. Not just buggered, but a very sloppy fit at that. Ordered a NOS one from Ebay and it was also a sloppy fit. So much so that you could screw it on just by rocking it back and forth and have it walk it's way down the threads... no turning needed. And.... the diameter is too big. It wouldn't fit inside the top triple hole.

So first things first... the loose fit:

Like the original, it came with two slots cut into it...

Decided to add a slot at every flat on the nut. Ain't used my hacksaw in so long I couldn't find it for a bit...

Then I used the vise to close down between the slots until I got a nice snug fit on the steering stem. I say snug... actually went too tight and had to work it some before it would screw on and off by hand.

So that cured the sloppy fit, but now it's tapered and still too large in dia to fit the hole in the top triple...

My Atlas is still a bit sickly, but feelin' good enough to tackle this job. So he said anyway. I put some aluminum tape on the jaws so I didn't ruin the chrome. Centering was achieved by putting a dead center in the tailstock, screwing the nut down on the steering stem and tightening the nut in the chuck. Once I had the chuck good and tight, it was turn the chuck out one thread and loosen the tailstock one thread. Rinse and repeat until the nut finally unscrewed itself...

Oh... and I didn't have a tailstock center big enough for the hole in the steering stem... so I have to half ass one of those too from a bolt...

Used my homemade tool post grinder with a well worn 1/16" cutoff wheel....

Kept grinding it down a few thousands at a time with test fits in between passes until I got a snug interference fit. And that just naturally cut all the taper off it.

...and here we are. It's a little more than hand tight in the hole and on the stem, but is easily tightened with a socket.

Cleaned and reinstalled the bearing balls and put it all back together. Bearing tension is now easily adjusted with a socket and the upper triple is snug around the nut... I'm happy. Victor sez he's happy too.

Where there's a will, there's a way

So, jus' to recap, the original nut was buggered courtesy a previous owner. Not just buggered, but a very sloppy fit at that. Ordered a NOS one from Ebay and it was also a sloppy fit. So much so that you could screw it on just by rocking it back and forth and have it walk it's way down the threads... no turning needed. And.... the diameter is too big. It wouldn't fit inside the top triple hole.

So first things first... the loose fit:

Like the original, it came with two slots cut into it...

Decided to add a slot at every flat on the nut. Ain't used my hacksaw in so long I couldn't find it for a bit...

Then I used the vise to close down between the slots until I got a nice snug fit on the steering stem. I say snug... actually went too tight and had to work it some before it would screw on and off by hand.

So that cured the sloppy fit, but now it's tapered and still too large in dia to fit the hole in the top triple...

My Atlas is still a bit sickly, but feelin' good enough to tackle this job. So he said anyway. I put some aluminum tape on the jaws so I didn't ruin the chrome. Centering was achieved by putting a dead center in the tailstock, screwing the nut down on the steering stem and tightening the nut in the chuck. Once I had the chuck good and tight, it was turn the chuck out one thread and loosen the tailstock one thread. Rinse and repeat until the nut finally unscrewed itself...

Oh... and I didn't have a tailstock center big enough for the hole in the steering stem... so I have to half ass one of those too from a bolt...

Used my homemade tool post grinder with a well worn 1/16" cutoff wheel....

Kept grinding it down a few thousands at a time with test fits in between passes until I got a snug interference fit. And that just naturally cut all the taper off it.

...and here we are. It's a little more than hand tight in the hole and on the stem, but is easily tightened with a socket.

Cleaned and reinstalled the bearing balls and put it all back together. Bearing tension is now easily adjusted with a socket and the upper triple is snug around the nut... I'm happy. Victor sez he's happy too.

Where there's a will, there's a way

Last edited:

Very nicely done!

Thanks Bob!

...there's a long lost relative...Where there's a will,

Indeed! Sometimes it's just dogged determination and an unwillingness to quit. Well done sirWhere there's a will, there's a way

Thanks Jeff!

Simply geniusSteering stem nut: Round 2.

So, jus' to recap, the original nut was buggered courtesy a previous owner. Not just buggered, but a very sloppy fit at that. Ordered a NOS one from Ebay and it was also a sloppy fit. So much so that you could screw it on just by rocking it back and forth and have it walk it's way down the threads... no turning needed. And.... the diameter is too big. It wouldn't fit inside the top triple hole.

So first things first... the loose fit:

Like the original, it came with two slots cut into it...

View attachment 241084

Decided to add a slot at every flat on the nut. Ain't used my hacksaw in so long I couldn't find it for a bit...

View attachment 241085

Then I used the vise to close down between the slots until I got a nice snug fit on the steering stem. I say snug... actually went too tight and had to work it some before it would screw on and off by hand.

So that cured the sloppy fit, but now it's tapered and still too large in dia to fit the hole in the top triple...

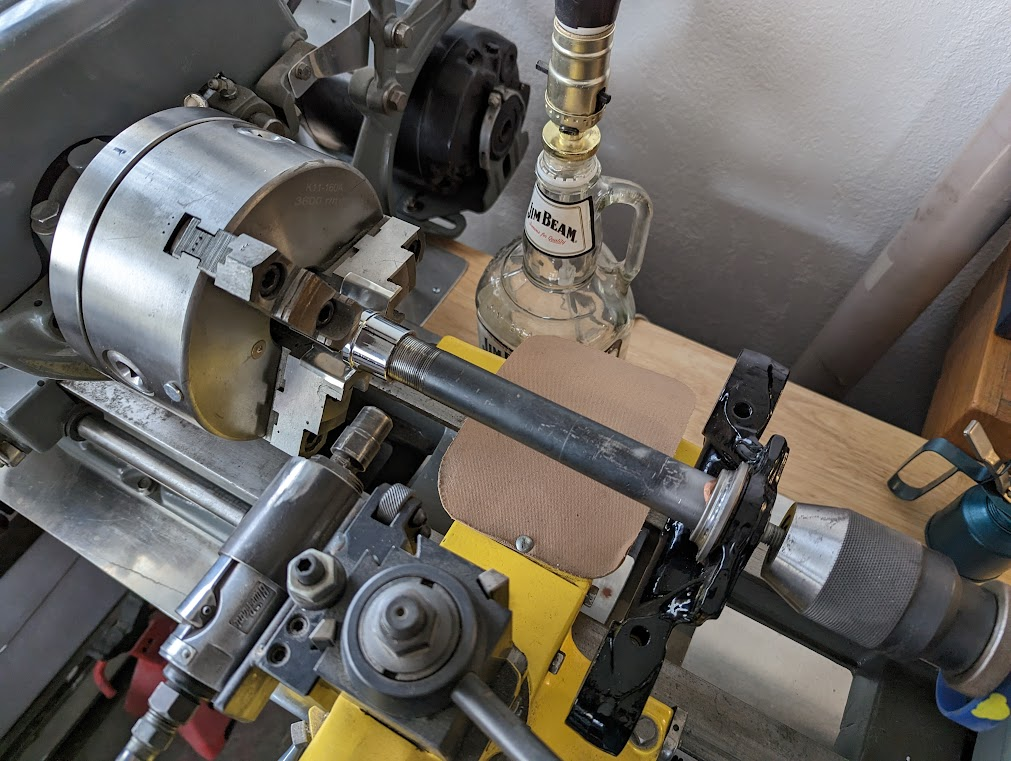

My Atlas is still a bit sickly, but feelin' good enough to tackle this job. So he said anyway. I put some aluminum tape on the jaws so I didn't ruin the chrome. Centering was achieved by putting a dead center in the tailstock, screwing the nut down on the steering stem and tightening the nut in the chuck. Once I had the chuck good and tight, it was turn the chuck out one thread and loosen the tailstock one thread. Rinse and repeat until the nut finally unscrewed itself...

View attachment 241086

View attachment 241088

Oh... and I didn't have a tailstock center big enough for the hole in the steering stem... so I have to half ass one of those too from a bolt...

View attachment 241087

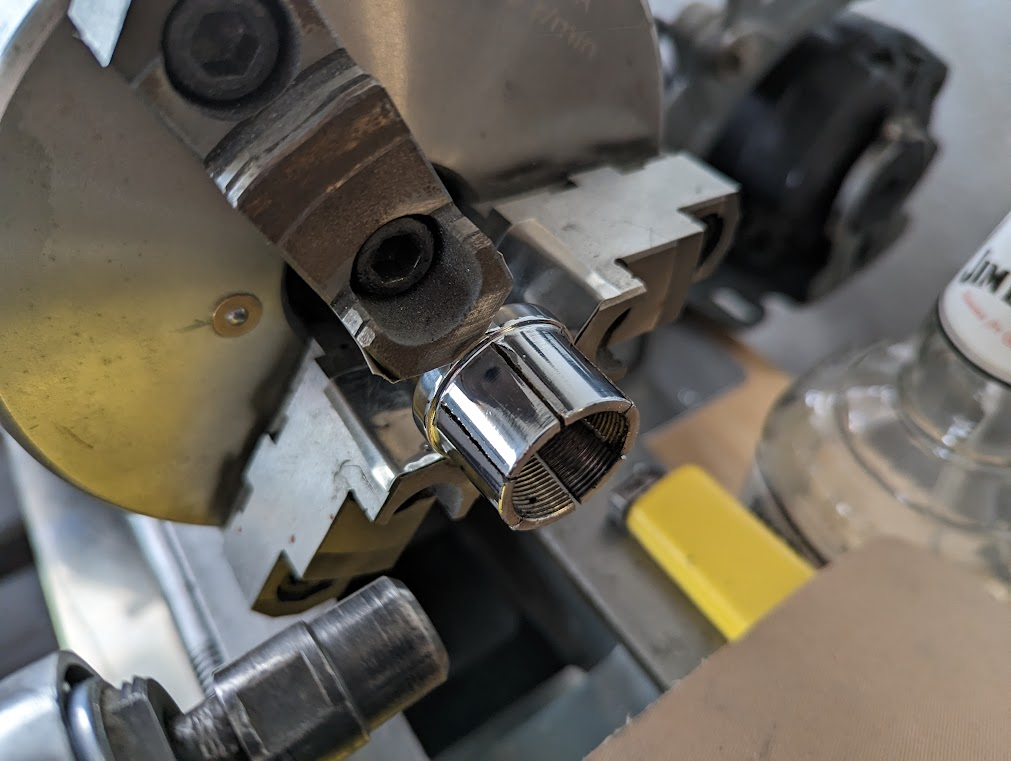

Used my homemade tool post grinder with a well worn 1/16" cutoff wheel....

View attachment 241089

Kept grinding it down a few thousands at a time with test fits in between passes until I got a snug interference fit. And that just naturally cut all the taper off it.

View attachment 241090

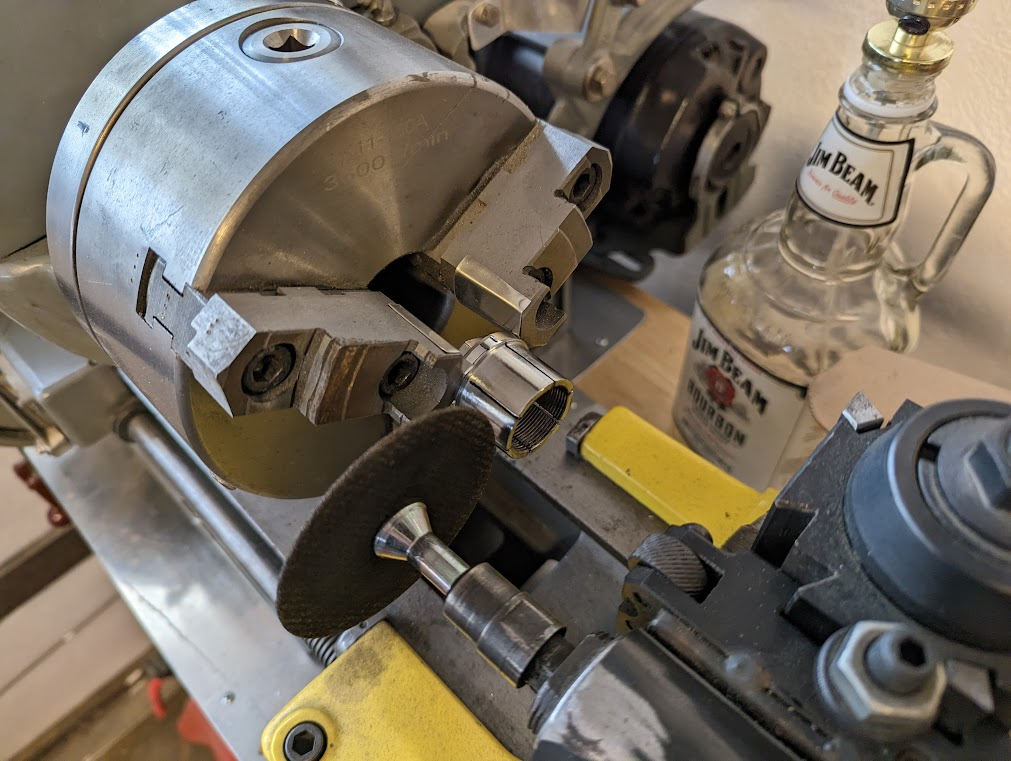

View attachment 241091

...and here we are. It's a little more than hand tight in the hole and on the stem, but is easily tightened with a socket.

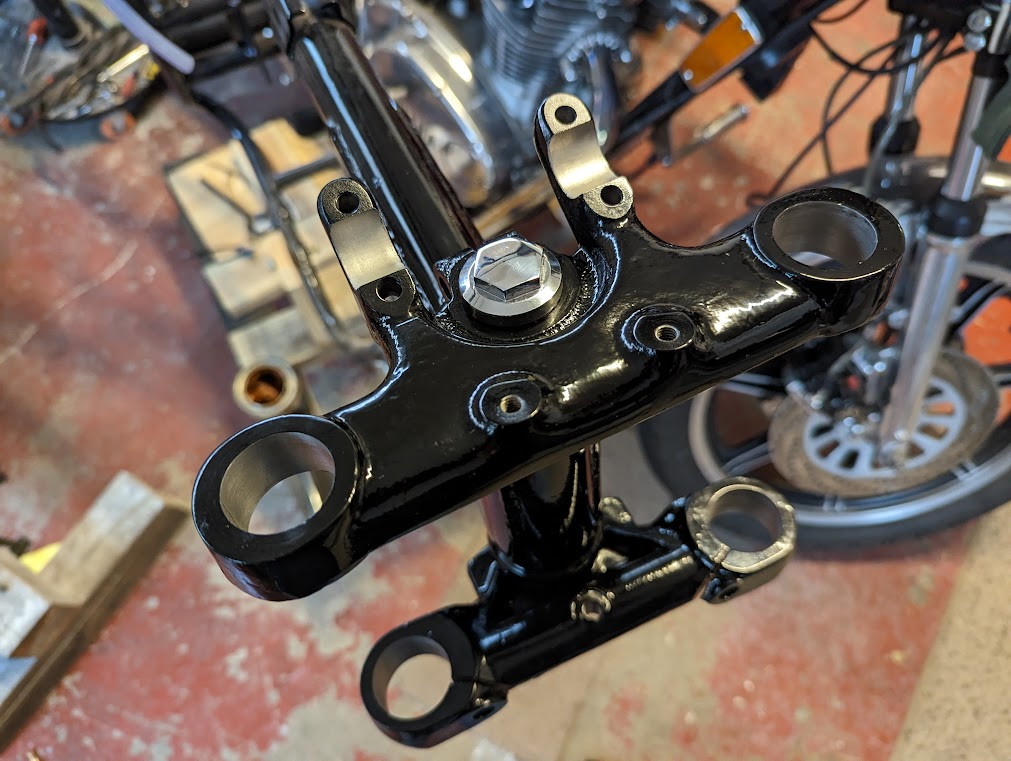

View attachment 241102

Cleaned and reinstalled the bearing balls and put it all back together. Bearing tension is now easily adjusted with a socket and the upper triple is snug around the nut... I'm happy. Victor sez he's happy too.

Where there's a will, there's a way

View attachment 241106

Machinist fella, you. "J. Dent - Creative Solutions to Unusual Problems"

Well I'm thinkin' Feked screwed up when they sent me the stuff I ordered. There's 3 rims to pick from.... chrome (mucho dinero). Polished stainless... again, pretty friggin' expensive... and unpolished stainless. They call it the "economy version."

Bein ' the cheap SOB that I am, I ordered the cheap one... then spent about 20 bucks on polish and felt pads for the grinder. Well, I finally pulled the wrapping off the front rim today and it's friggin' polished... had remnants of polish all over it. Turned my hands black in about 30 sec.

Cool beans!! Mind you, I'm not complaining a bit. Maybe they were out of the unpolished ones and sent me these so it didn't go backorder.... dunno. At any rate, I'm a happy camper.

I'd planned on spending the afternoon polishing. Phew... dodged that. So I went ahead and laced it up. One minor screwup.... there's a zerk that goes in the middle of the hub. Meant to put that back before I laced. Oh well... minor. I can still install it, it's just gonna be a bit of a pain. Now I gotta clean up and reinstall the bearings and I can test out my new wheel stand.

Bein ' the cheap SOB that I am, I ordered the cheap one... then spent about 20 bucks on polish and felt pads for the grinder. Well, I finally pulled the wrapping off the front rim today and it's friggin' polished... had remnants of polish all over it. Turned my hands black in about 30 sec.

Cool beans!! Mind you, I'm not complaining a bit. Maybe they were out of the unpolished ones and sent me these so it didn't go backorder.... dunno. At any rate, I'm a happy camper.

I'd planned on spending the afternoon polishing. Phew... dodged that. So I went ahead and laced it up. One minor screwup.... there's a zerk that goes in the middle of the hub. Meant to put that back before I laced. Oh well... minor. I can still install it, it's just gonna be a bit of a pain. Now I gotta clean up and reinstall the bearings and I can test out my new wheel stand.