I’m unsure of the now days prices for sure on most parts. I thought the same but gotta have em.Hopefully they be what I’m paying up for.Wow, that's a lot of money for 2 dust boots and 2 fork seals, lol. $42.05 for a fork seal, that's robbery.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

75b Frontend redo and deep clean

- Thread starter magoo66

- Start date

Yes pretty steep, but the parts they supply are premium, the darn shipping cost is also a painful reminder the rebuilding these old ladies easily adds up! Don’t look back

Its been a long time

Doesn't know nothing.

I just wouldn't pay that. As long as they're a standard size, good quality fork seals are readily available.Wow, that's a lot of money for 2 dust boots and 2 fork seals, lol. $42.05 for a fork seal, that's robbery.

As a matter of interest, anyone know the size of fork seals?

That happened to me twice with Shinko tires. I had to really clean and polish up the inner lip and use plenty of lube And put about 100 lbs of pressure to get it to pop out. Went with a set of Kenda’s for my last tires and no issues. Of course those were also steel rimsWow, I surely did a hurried half-assed job mounting a new tire shortly after I acquired this bike.

Stopped at W/M after work and processed about 30 reference photos I’d taken during disassembly.Always good to have handy I’ve learned through the years at assembly time.Started first steps of cleaning and polishing forks while waiting for rebuild parts to arrive and before disassembling.

Attachments

Forks get a lot of sludge built up inside over time. But since they don't get very hot in operation, when you drain the oil, that sludge stays in there. You really need to take them apart and actually swab the inside of the lower out. I made a "special tool" for this. It's nothing more than some ¼" rod with a little eye bent on the end. You thread a rag into it, dip it in solvent, and use it like a ramrod to clean out the lower leg .....

And when prying out the old seals, you need a way to protect the top of the soft aluminum fork leg. So, I made another little "special tool" for this as well. It's jut a small piece of aluminum angle with a couple slits cut in it and the center "finger" bent down. It sits all by itself atop the lower .....

And for prying the seals out, I modded an old square shank screwdriver by rounding the tip. The square shank keeps it from rolling one way or the other as you pry .....

And when prying out the old seals, you need a way to protect the top of the soft aluminum fork leg. So, I made another little "special tool" for this as well. It's jut a small piece of aluminum angle with a couple slits cut in it and the center "finger" bent down. It sits all by itself atop the lower .....

And for prying the seals out, I modded an old square shank screwdriver by rounding the tip. The square shank keeps it from rolling one way or the other as you pry .....

Nice idea and simple too

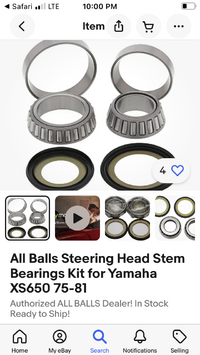

That is a good set! I used two of those and then used the XS Performance set last time. They worked fine but the bearings aren’t as heavy duty IIRC.

Good to know.Worked on many an xs but new to the roller bearing steering update.I’ve reviewed many other’s experiences with this subject here in the site and foresee no issues. ThanksThat is a good set! I used two of those and then used the XS Performance set last time. They worked fine but the bearings aren’t as heavy duty IIRC.

You will notice that the tapered bearings will add just a slight bit of difference. They will hold the stem out just a bit on the bottom resulting in some extra space on the forks so that the bucket ears may be a little loose. I always solved it with an o-ring added on the forks.

I guess what I’m saying is they don’t appear to seat as deeply as the OEM balls and races but it’s not an issue.

Just a note on that bearing install - on the bottom, use both the original rubber ring seal and the seal that comes with the bearings. On the top, you don't need any seal (you can leave it out). Gravity pulls the grease down so a seal on the very top doesn't do anything. Also, since you have it all apart, now is the time to install a grease fitting in the steering neck. This allows you to keep the bearings greased without having to take anything apart .....

You will need to plug the open bottom of the steering neck though, or the grease you pump in will just come out there (from the hole in the neck for the steering lock). I just used an old wine bottle cork. Initially, it will take quite a bit of grease to fill the neck and stem before any starts getting pushed into the bearings. You can reduce that amount a little by installing what we call a "grease saver". This is nothing more than a length of plastic hose from the hardware store slipped over the neck .....

The above pic is of a Special stem. It has an external fork lock so the stem can be covered. On your Standard, you won't be able to do that or you'll block the fork lock hole. You can only install one about 1/3 of the way up, but it'll help a little.

You will need to plug the open bottom of the steering neck though, or the grease you pump in will just come out there (from the hole in the neck for the steering lock). I just used an old wine bottle cork. Initially, it will take quite a bit of grease to fill the neck and stem before any starts getting pushed into the bearings. You can reduce that amount a little by installing what we call a "grease saver". This is nothing more than a length of plastic hose from the hardware store slipped over the neck .....

The above pic is of a Special stem. It has an external fork lock so the stem can be covered. On your Standard, you won't be able to do that or you'll block the fork lock hole. You can only install one about 1/3 of the way up, but it'll help a little.

The waiting on parts list is growing.Presents to me from me.Early Christmas.lol

All Balls also has a fork seal kit that's a lot cheaper, if it's not too late to cancel the Partzilla order.

They've worked fine for coming up on five yrs now on my bike.

https://www.allballsracing.com/56-177.html

All Balls also has a fork seal kit that's a lot cheaper, if it's not too late to cancel the Partzilla order.

They've worked fine for coming up on five yrs now on my bike.

https://www.allballsracing.com/56-177.html

View attachment 261252

Shipped yesterday from Partzilla. I’ll definitely keep these in mind in case I do in fact do another set. Thanks JimAll Balls also has a fork seal kit that's a lot cheaper, if it's not too late to cancel the Partzilla order.

They've worked fine for coming up on five yrs now on my bike.

https://www.allballsracing.com/56-177.html

View attachment 261252

Did the removal of factory clear from the forks this evening using the process I’ve always used for aluminum before the polishing process.Seemingly there is seldom a heavy MIL thickness but it’s always there and needs removed.An excess wipe off of stripper,a hot soapy water bath.Cleaning done for now and ready to rebuild.The parts wait continues.

Attachments

That stripper any good for other, more stubborn paint?

I shoulda tried that when I did my frame on my 1970 CB350. I spray bombed it with VHT Rollbar and Frame paint. It turned out pretty good, but its much more satin looking than I had hoped it would be.This is all I’ve used for over 50years on frames.Tried a few with the older acrylic enamel with hardener on some when requested when I ran my shop but seemingly customers would scratch or chip reassembling and expect it was easy to redo. I went back to rust oleum only and always have great results. I spray it on complete bare frame projects.For minor touch up or dressing up like this brushing works well.It’s forgiving and flows out fine. I only cut it with acetone.Not mineral spirits nor definitively not lacquer thinner.

It is Jim.This is all I’ve ever used even before I had the big commercial blasting set-ups I’d put it on for some heavier paint build up when I had small blasters.As a kid Mom refinished a mega bunch.All she used.Not that there isn’t better and probably less toxic available but this works fine.Learned young with stripper to not back and forth stroke when applying.One direction strokes only.

Should you do another and use the same R/O black in a rattle can,provided you’re doing over the prepped existing factory black and not bare metal, start with a couple coats of R/O flat black before cover spraying the gloss black.Re;You’ll not be as likely to get a run or many as we’re all after the shine and tend to add a bit extra to keep it shiny while applying.It works.I shoulda tried that when I did my frame on my 1970 CB350. I spray bombed it with VHT Rollbar and Frame paint. It turned out pretty good, but its much more satin looking than I had hoped it would be.