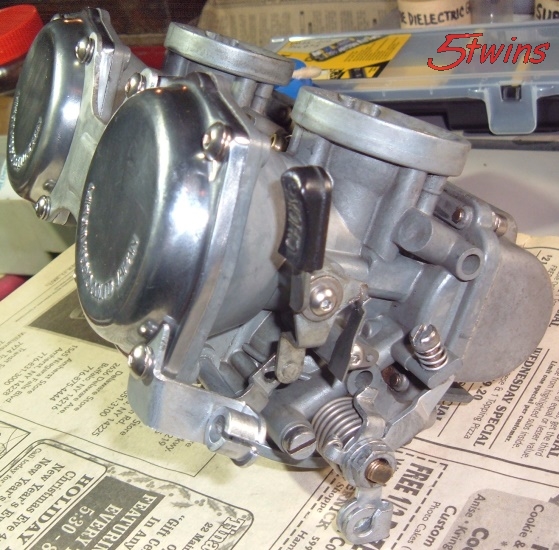

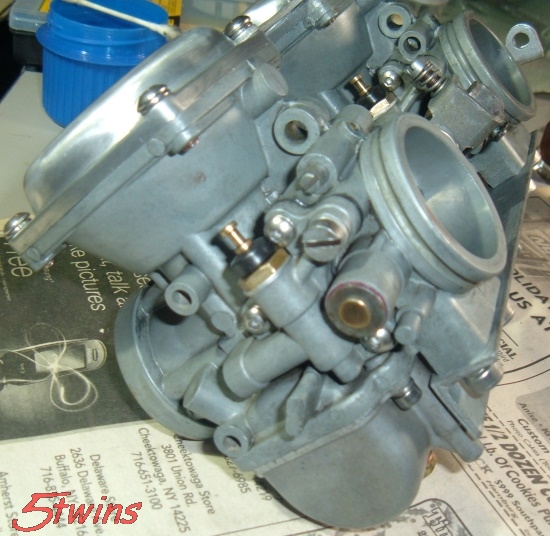

One of the things I do when rebuilding a set of carbs is replace all the original Phillips screws with stainless Allens. I used to use regular Allens everywhere but have changed now to buttonhead Allens on the tops and sides, and regular Allens on just the bowls and that angle bracket across the bottom. I think the smaller, more rounded off buttonheads look better and blend in better with the carb body .....

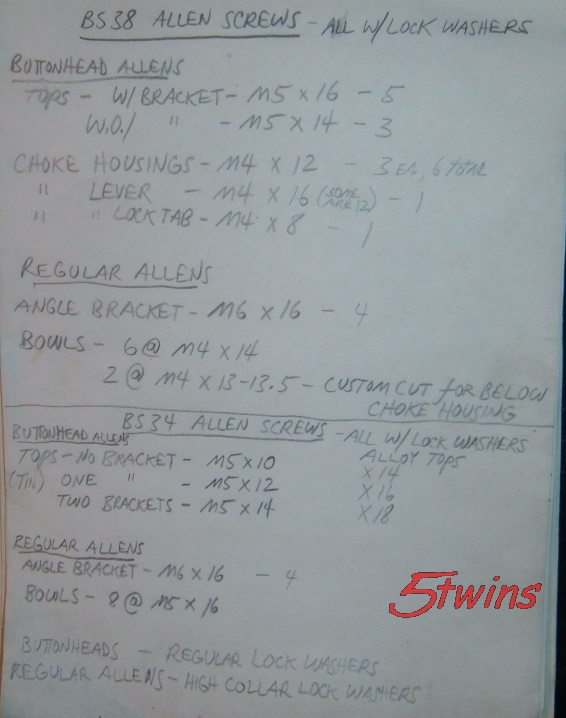

So, with all the carb work I've been doing over the last few months, I thought it was time I made up a list so I don't have to re-measure stuff all the time, lol ..... and here it is .....

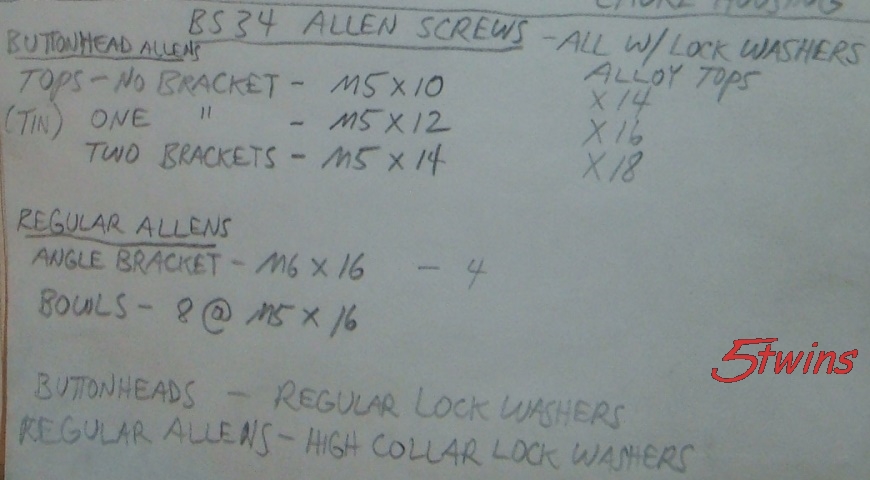

..... and some closer shots of the BS38 and BS34 sections .....

(sneaking this in here, ggg)

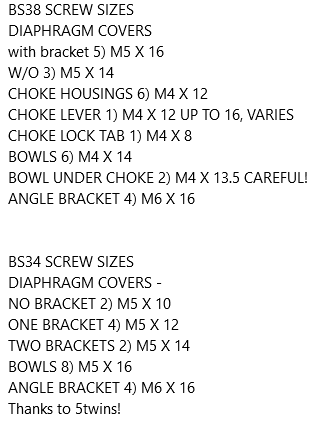

BS38 SCREW SIZES

DIAPHRAGM COVERS

with bracket 5) M5 X 16

W/O 3) M5 X 14

CHOKE HOUSINGS 6) M4 X 12

CHOKE LEVER 1) M4 X 12 UP TO 16, VARIES

CHOKE LOCK TAB 1) M4 X 8

BOWLS 6) M4 X 14

BOWL UNDER CHOKE 2) M4 X 13.5 CAREFUL!

ANGLE BRACKET 4) M6 X 16

BS34 SCREW SIZES

DIAPHRAGM COVERS -

NO BRACKET 2) M5 X 10

ONE BRACKET 4) M5 X 12

TWO BRACKETS 2) M5 X 14

BOWLS 8) M5 X 16

ANGLE BRACKET 4) M6 X 16

Thanks to 5twins!

same info as a JPG

Some notes and explanations will follow in the next post.

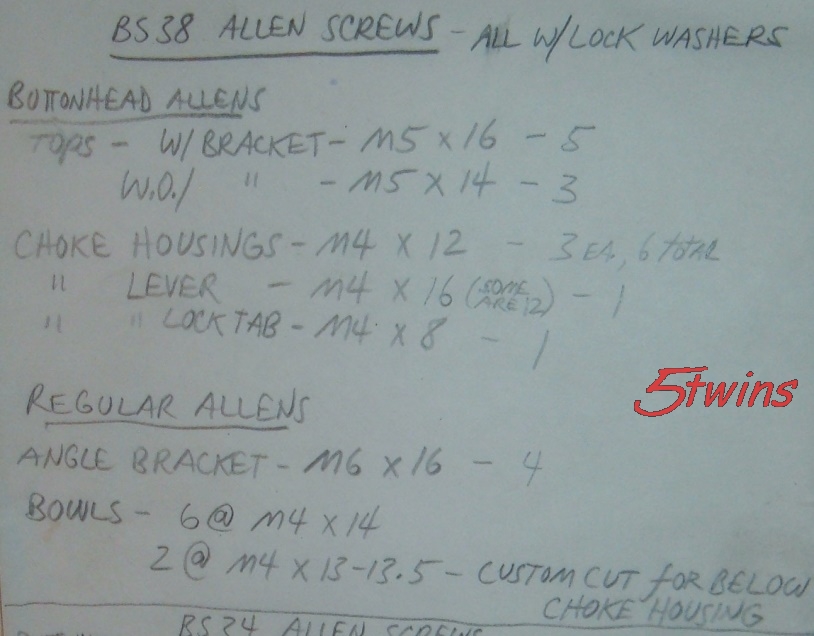

So, with all the carb work I've been doing over the last few months, I thought it was time I made up a list so I don't have to re-measure stuff all the time, lol ..... and here it is .....

..... and some closer shots of the BS38 and BS34 sections .....

(sneaking this in here, ggg)

BS38 SCREW SIZES

DIAPHRAGM COVERS

with bracket 5) M5 X 16

W/O 3) M5 X 14

CHOKE HOUSINGS 6) M4 X 12

CHOKE LEVER 1) M4 X 12 UP TO 16, VARIES

CHOKE LOCK TAB 1) M4 X 8

BOWLS 6) M4 X 14

BOWL UNDER CHOKE 2) M4 X 13.5 CAREFUL!

ANGLE BRACKET 4) M6 X 16

BS34 SCREW SIZES

DIAPHRAGM COVERS -

NO BRACKET 2) M5 X 10

ONE BRACKET 4) M5 X 12

TWO BRACKETS 2) M5 X 14

BOWLS 8) M5 X 16

ANGLE BRACKET 4) M6 X 16

Thanks to 5twins!

same info as a JPG

Some notes and explanations will follow in the next post.

Last edited by a moderator: