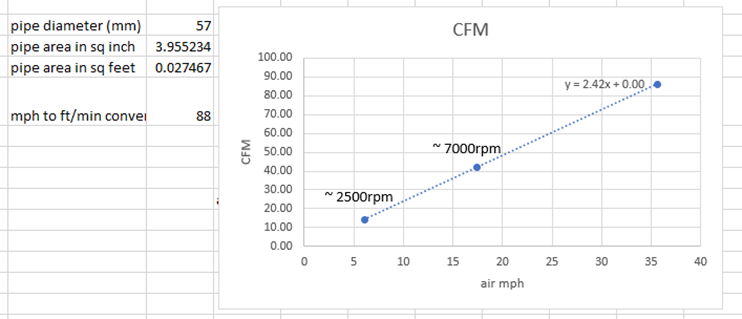

I wanted to understand the differences in flow for various intake options. So I have setup a simple experiment to compare the stock XS650E airbox to UNI pods and a few other configurations. The “flow bench” is made using an old anemometer and a “wind tunnel” out of PVC pipes that closely matched the air filter/box outlets and the anemometer fan enclosures’ inner diameter. A shop vac was used for the source of suction with washers to change the air flow through the setup.

The anemometer measured wind speed in miles per hour. “Tested” its accuracy hanging it out of the car window while driving on a clam day while setting cruise control for different mph settings. It reads as expected.

The cubic feet per minute (CFM) is calculated by multiplying the speed reading by mph to feet per minute conversion factor and then multiplying the product by the anemometer/pipe inner diameter cross sectional area in square feet:

In the test I compared three settings for the air flow that would be equivalent to the engine speed of ~2500rpm, ~7000rpm and vacuum inlet wide open, a theoretical ~ 14000 rpm.

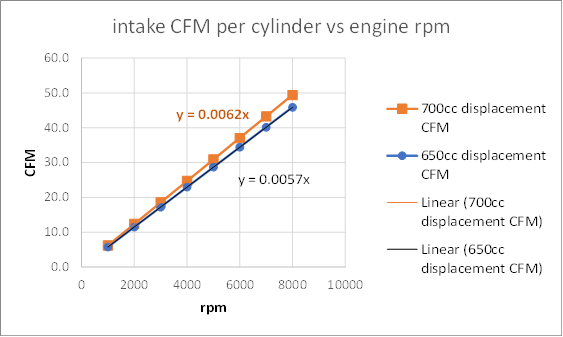

(To calculate intake CFM for one cylinder for a given engine speed use cylinder displacement value (325cc for a stock setup), convert to cubic inches( 21.36 ci) then intake CFM = (engine displacement * rpm)/(2*12inch^3)

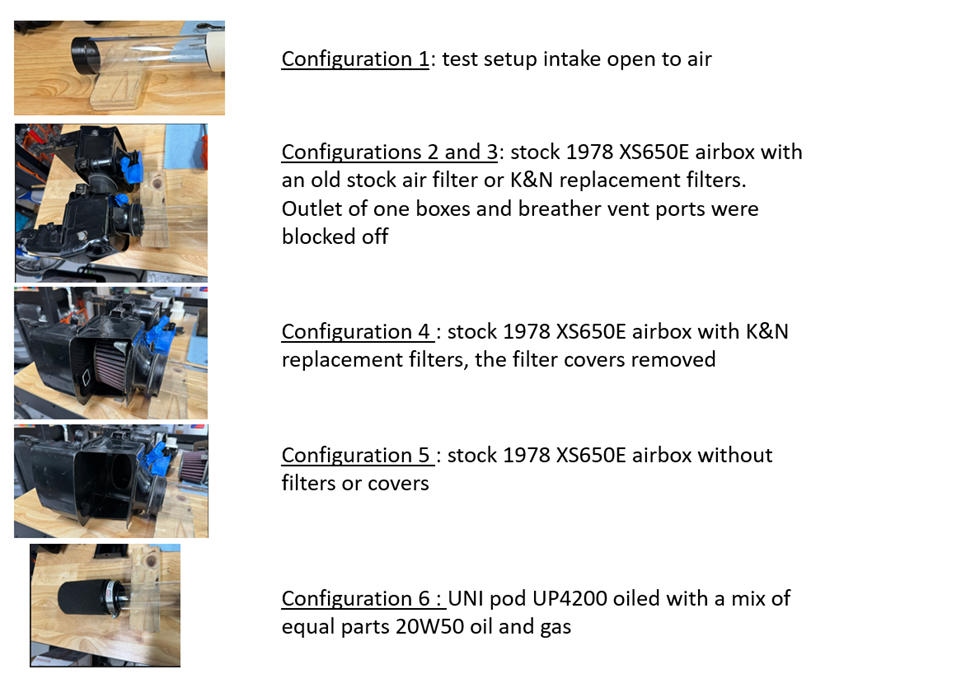

Here are the configurations tested:

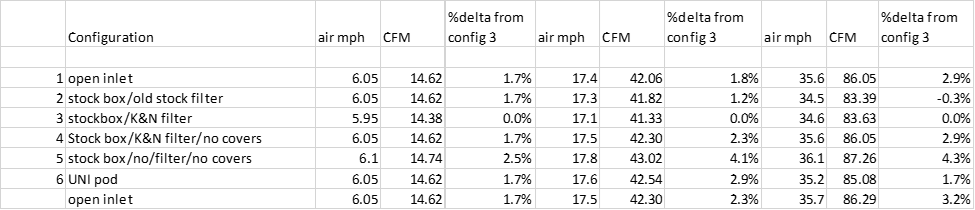

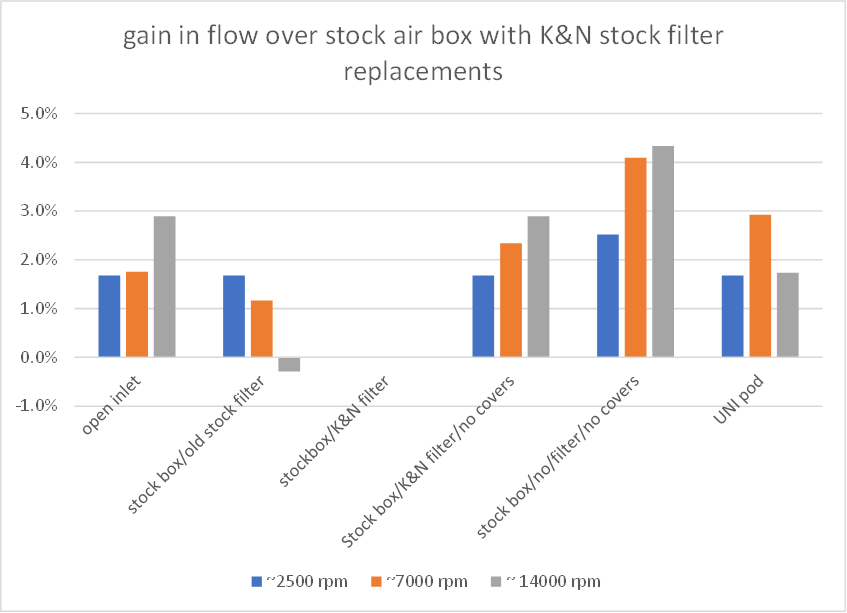

Here is the raw data and a bar chart for relative comparison of flow at different engine speeds:

Some comments and observations:

The stock filter I had is something I received with a spare airbox, it is very used and I have questions about its integrity. That is why it may be flowing better than K&N at low engine speed, but one can see how its relative performance is dropping with the flow rate. The K&N has been in my bike for some time. It is fairly clean and well oiled, but I did not clean it specifically for this test.

The anemometer may not have enough resolution to capture fully the differences in flow as it had only one decimal in the mph reading. Where the first decimal would flip between adjacent reading back and forth, I would add a 0.05 to the lowest number.

It is no surprise that the open inlet does not provide the best flow as usually there is turbulence at inlet. The open box provides the best flow. That also makes sense as the construction of the box incorporates a velocity stack-type funnel at the inlet that smoothers out the flow.

Both UNI pods and the stock box without the filter covers give a 2-3% boost in the air flow. It is a bit strange that the relative improvement of flow of the UNI pods repeatably dropped off at the highest intake velocity (though not very relevant for the operating range of XS 650).

The 2-3% improvement in air flow would necessitate a 2, maybe 3 steps up in the main jet size as the jet sizes correspond to the flow rates of the jets. (follow the discussion here: http://rd500lc.free.fr/technics/jet_size_en.htm). This jet size increase is inline with expectations

Modifying/opening up the filter covers of the stock box seems like an attractive option (to me at least).

The anemometer measured wind speed in miles per hour. “Tested” its accuracy hanging it out of the car window while driving on a clam day while setting cruise control for different mph settings. It reads as expected.

The cubic feet per minute (CFM) is calculated by multiplying the speed reading by mph to feet per minute conversion factor and then multiplying the product by the anemometer/pipe inner diameter cross sectional area in square feet:

In the test I compared three settings for the air flow that would be equivalent to the engine speed of ~2500rpm, ~7000rpm and vacuum inlet wide open, a theoretical ~ 14000 rpm.

(To calculate intake CFM for one cylinder for a given engine speed use cylinder displacement value (325cc for a stock setup), convert to cubic inches( 21.36 ci) then intake CFM = (engine displacement * rpm)/(2*12inch^3)

Here are the configurations tested:

Here is the raw data and a bar chart for relative comparison of flow at different engine speeds:

Some comments and observations:

The stock filter I had is something I received with a spare airbox, it is very used and I have questions about its integrity. That is why it may be flowing better than K&N at low engine speed, but one can see how its relative performance is dropping with the flow rate. The K&N has been in my bike for some time. It is fairly clean and well oiled, but I did not clean it specifically for this test.

The anemometer may not have enough resolution to capture fully the differences in flow as it had only one decimal in the mph reading. Where the first decimal would flip between adjacent reading back and forth, I would add a 0.05 to the lowest number.

It is no surprise that the open inlet does not provide the best flow as usually there is turbulence at inlet. The open box provides the best flow. That also makes sense as the construction of the box incorporates a velocity stack-type funnel at the inlet that smoothers out the flow.

Both UNI pods and the stock box without the filter covers give a 2-3% boost in the air flow. It is a bit strange that the relative improvement of flow of the UNI pods repeatably dropped off at the highest intake velocity (though not very relevant for the operating range of XS 650).

The 2-3% improvement in air flow would necessitate a 2, maybe 3 steps up in the main jet size as the jet sizes correspond to the flow rates of the jets. (follow the discussion here: http://rd500lc.free.fr/technics/jet_size_en.htm). This jet size increase is inline with expectations

Modifying/opening up the filter covers of the stock box seems like an attractive option (to me at least).

Last edited: